![]()

2022-03-14

181

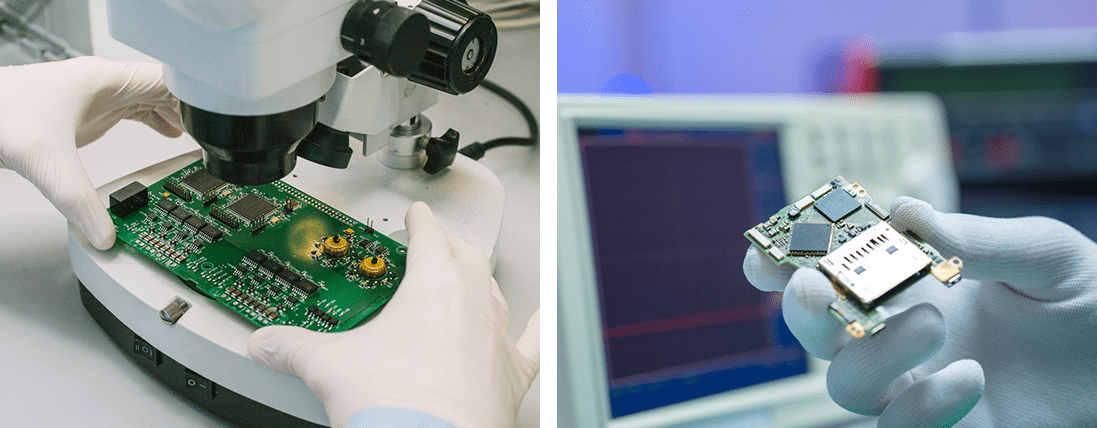

Automated X-ray Inspection (AXI)

Testing the layer offset with X-ray technology is very important in the manufacture of

multilayer circuit boards. X-ray images are the best (and only) way to identify and

correct layer displacements in the pressing process.

Drill holes in multilayer circuit boards are also optimized using X-ray images.

Any minor deviations in the geometry of the circuit board image compared to the

geometry of the drill hole coordinates will be identified. By changing a correction

factor within a clearly defined tolerance range, it can be ensured that the optimum

drill reference point will be determined for each axis, with an optimal interpolation

for all layers. These corrections take place in the µm range!

Automated X-ray inspection is used in a

wide range of industries and applications, predominantly with two major goals:

-

Process optimization, i.e. the results of the inspection are used

to optimize following processing steps,

-

Anomaly detection, i.e. the result of the inspection serve as a

criterion to reject a part (for scrap or re-work).

Principle of Operation

While optical inspection produces full color images of the surface of the object, x-ray inspection transmits x-rays through the object and records gray scale images of the shadows cast. The image is then processed by image processing software that detects the position and size/ shape of expected features (for process optimization) or presence/ absence of unexpected/ unintended objects or features (for anomaly detection).

X-rays are generated by an x-ray tube, usually located directly above or below the object under inspection. A detector located the opposite side of the object records an image of the x-rays transmitted through the object. The detector either converts the x-rays first into visible light which is imaged by an optical camera, or detects directly using an x-ray sensor array. The object under inspection may be imaged at higher magnification by moving the object closer to the x-ray tube, or at lower magnification closer to the detector.

Since the image is produced due to the different absorption of x-rays when passing through the object, it can reveal structures inside the object that are hidden from outside view.

Well-known PCB supplier

Well-known PCB supplier