Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

In today’s fast-moving tech landscape, choosing the right aluminum PCB manufacturer is more than just a supply chain decision—it’s a business-critical move that can directly impact the success of your product. As electronics become more compact and powerful, the demand for effective thermal management solutions grows exponentially. Aluminum PCBs, known for their excellent heat dissipation capabilities, have become the go-to solution for applications in LED lighting, automotive electronics, telecommunications, and industrial controls.

But here’s the truth many overlook: PCB manufacturing is not a one-time event. Passing inspection once doesn’t guarantee the next batch will meet the same standard. That’s why evaluating a manufacturer based on consistent, long-term performance—not just a single delivery—is essential.

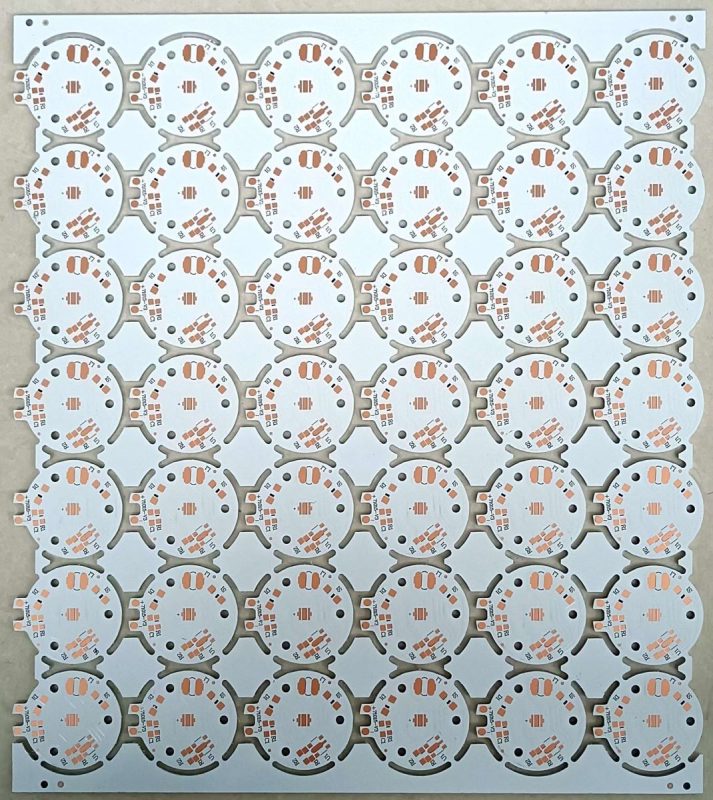

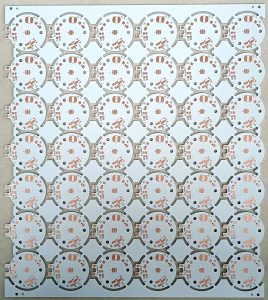

Aluminum PCB Manufacturer

Not all PCB defects are visible to the naked eye. Some issues can be caught during basic inspection at the client’s site. Others, however, lie dormant—only revealing themselves after assembly is completed, or worse, after weeks or months of real-world use. When this happens, the damage is done. Time is lost. Costs pile up. Rework becomes inevitable.

Even more dangerous are delayed failures—subtle PCB defects that only show up after prolonged product usage. And by the time you discover the root cause, you may have already produced and shipped dozens of batches, with thousands of units in customers’ hands across the globe.

What do you do then?

How do you trace the defective batches?

Can you recall the faulty units?

How do you protect your brand and credibility?

What about the impact on your downstream production or end-user satisfaction?

These are real risks. And they come with real consequences.

This is why choosing a professional, responsible, and communicative PCB manufacturer is not optional—it’s mission-critical. The consequences of working with an unreliable supplier can be devastating: delays, hidden defects, warranty claims, and worst of all, a damaged brand reputation.

A great aluminum PCB manufacturer is not just a vendor. They’re a partner—one who takes ownership of every board, every layer, every trace.

They understand your pressure, your timelines, your engineering constraints. They’re proactive in problem-solving and transparent in their processes. They help you avoid problems before they happen—not just react after the damage is done.

Aluminum PCBs are used in high-power environments because of their ability to transfer heat efficiently. A qualified manufacturer must understand the science behind thermal conductivity and material selection to design boards that support long-term performance.

Look for a track record of success in industries like automotive, LED lighting, power supply, and industrial electronics. This shows the manufacturer’s ability to meet strict tolerance, heat, and performance requirements.

Great manufacturers understand how the choice of aluminum substrate, copper weight, dielectric layer, and surface finish all impact board performance. They offer guidance, not just production.

Aluminum PCBs often require advanced CNC and routing equipment to handle the material’s rigidity and thermal demands. Manufacturers should be equipped with clean, modern, high-speed drilling machines for maximum precision.

Consistent trace quality, smooth vias, and accurate solder masks are critical for reliability. Only top-tier manufacturers offer cleanroom environments and tight process controls to maintain quality across batches.

Whether it’s impedance control, thermal cycling, or AOI inspections, internal quality control systems must be robust, repeatable, and transparent. QC is not an afterthought—it’s a core part of the process.

International certifications prove that the manufacturer adheres to globally recognized quality, safety, and environmental standards. Don’t settle for suppliers without ISO9001, UL, and RoHS compliance.

For specialized applications like automotive, medical, and defense electronics, the manufacturer should meet TS16949, IPC standards, and other relevant industry requirements.

From quick-turn prototyping to high-volume orders, flexibility is key. A quality partner can adjust to your scaling needs while keeping lead times short.

Need ENIG, OSP, HASL, or immersion silver? A great manufacturer will offer a range of finish options and suggest the right one based on function and cost.

Fast quoting, transparent updates, and real-time communication save you time and reduce uncertainty.

A manufacturer should offer DFM (Design for Manufacturability) feedback, help you solve layout challenges, and work with you to optimize for cost and performance.

When issues do arise, a professional partner helps troubleshoot and provides documentation, analysis, and improvements—building trust, not deflection.

Price matters. But value matters more. A professional PCB manufacturer offers competitive pricing without cutting corners. They apply value engineering techniques to reduce unnecessary cost while ensuring the product meets specs.

No ISO/UL certifications

Poor or no QC documentation

Inconsistent delivery times

Lack of engineering support

Delayed or unclear communication

Avoid these, and you avoid most major risks.

Jerico Multylayer PCB doesn’t just understand what makes a qualified aluminum PCB manufacturer—we live by those standards.

We recognize that one good batch doesn’t prove reliability. We know that some defects only show up after assembly—or months into usage—and we design our processes to catch these issues before they reach your production line.

From raw material inspection to final delivery, our processes are optimized for consistency, traceability, and accountability. And when something goes wrong, we work with you, not against you.

Our goal is simple:

To be your strongest partner, not just your supplier.

A truly great aluminum PCB manufacturer is more than a factory.

They’re your engineering ally, your quality gatekeeper, and your risk-reducing partner.

Choose wisely—and your product will reflect that decision in every circuit, every test, and every satisfied customer.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote