Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

In the world of electronics, the importance of printed circuit boards (PCBs) cannot be overstated. These essential components form the foundation of almost every modern device, from smartphones to industrial machines. When it comes to creating PCBs, selecting the right material is critical to ensuring both performance and longevity. The material choice impacts everything from signal integrity to durability. This article explores the top types of PCB materials, discussing their properties, advantages, and best-use applications. By understanding the various options, manufacturers can make informed decisions about the materials that will best suit their projects.

Types of PCB Materials

PCB materials play a crucial role in determining the overall functionality and reliability of a printed circuit board. The choice of material affects the thermal performance, signal integrity, and mechanical strength of the board. In this section, we will introduce the primary types of PCB materials used in the manufacturing process, including their properties and key uses. The most common materials include FR4, CEM1, CEM3, polyimide, aluminum, ceramic, and Rogers.

What’s the real story? Each type of PCB material has its own set of strengths and weaknesses, which makes it suited to different applications. The ideal material depends on the specific requirements of the product being developed, including environmental conditions, signal frequency, and thermal management.

| PCB Material | Common Uses | Characteristics |

|---|---|---|

| FR4 | Consumer electronics, computers | Strong, durable, cost-effective, and widely used |

| CEM1 | Single-sided PCBs | Lightweight, low-cost, good insulation |

| CEM3 | Multi-layer PCBs | Enhanced strength, good for moderate complexity |

| Polyimide | Flexible PCBs | Heat-resistant, flexible, high-performance |

| Aluminum | LED boards, power electronics | Excellent heat dissipation properties |

| Ceramic | High-temperature and high-frequency applications | Stable at high temperatures, excellent electrical insulation |

| Rogers | High-frequency applications | Low loss, stable performance at high speeds |

FR4, short for “Flame Retardant 4,” is the most commonly used PCB material. It is made from woven fiberglass cloth and an epoxy resin binder. This combination offers excellent electrical insulation, mechanical strength, and resistance to heat and environmental stress. But here’s the kicker—FR4 is not just about durability; it’s also about versatility. It can be used in both rigid and flexible PCBs, making it suitable for a wide range of applications, from consumer electronics to automotive systems.

FR4 is favored by manufacturers due to its affordability and well-balanced properties. Its widespread use can be attributed to its ability to handle moderate to high-frequency signals and its compatibility with standard PCB manufacturing processes. What’s more, FR4 is available in various thicknesses and configurations, allowing designers to select the optimal material for their specific needs.

| Advantage of FR4 | Description |

|---|---|

| Cost-effective | Affordable compared to other high-performance materials |

| Durability | Provides good mechanical strength and heat resistance |

| Versatility | Suitable for a variety of applications and configurations |

CEM1 is a composite material primarily used for single-sided PCBs. It consists of paper-based phenolic or epoxy resin with a copper-clad layer. Compared to FR4, CEM1 is generally cheaper and lighter, making it an attractive option for basic, low-cost applications. However, it has a lower mechanical strength and is less durable than FR4. CEM1’s insulating properties are sufficient for applications that do not require complex or multi-layer designs.

What’s the real story? While CEM1 may not be suitable for high-performance devices, it’s a great option for simple, cost-sensitive projects. It’s commonly found in consumer products where durability is not as critical, like simple household electronics.

| CEM1 Properties | Characteristics |

|---|---|

| Cost | Lower cost compared to FR4 |

| Strength | Weaker than FR4, suitable for simple applications |

| Durability | Not as durable as FR4, suitable for single-sided PCBs |

CEM3 is a composite material similar to CEM1 but with improved mechanical properties. It is made from woven glass fabric impregnated with epoxy resin, which offers better strength than CEM1. CEM3 is typically used in more complex applications, such as multi-layer PCBs. It’s a popular choice for moderate-complexity designs and offers a balance of performance and cost. Compared to FR4, CEM3 provides better mechanical strength and can be used for applications that require higher layer counts and more intricate designs.

This is where it gets interesting: CEM3 offers the best of both worlds—cost-effectiveness and performance. Its ability to handle more complex designs without significantly increasing production costs makes it an attractive option for industries like telecommunications and industrial electronics.

| CEM3 Features | Benefits |

|---|---|

| Mechanical Strength | Superior to CEM1, suitable for multi-layer designs |

| Cost | More cost-effective than FR4 for medium-complexity projects |

| Application | Used in moderate-complexity electronic devices |

Polyimide is a high-performance polymer material that is widely used for flexible PCBs. Its exceptional thermal stability, high dielectric strength, and flexibility make it ideal for applications where the PCB needs to bend or fit into tight spaces. Polyimide’s ability to withstand high temperatures without losing its properties makes it a go-to choice for applications such as wearable electronics, automotive, and medical devices.

But here’s the kicker—polyimide doesn’t just offer flexibility; it also delivers reliability. It can handle complex designs with fine traces and is resistant to environmental factors like humidity, chemicals, and mechanical stress. Polyimide is the material of choice for electronics that need to endure extreme conditions while maintaining performance.

| Polyimide Features | Applications |

|---|---|

| Flexibility | Ideal for wearable electronics and flexible circuits |

| Durability | High thermal stability, resistant to environmental stress |

| Performance | Used in high-frequency, high-performance devices |

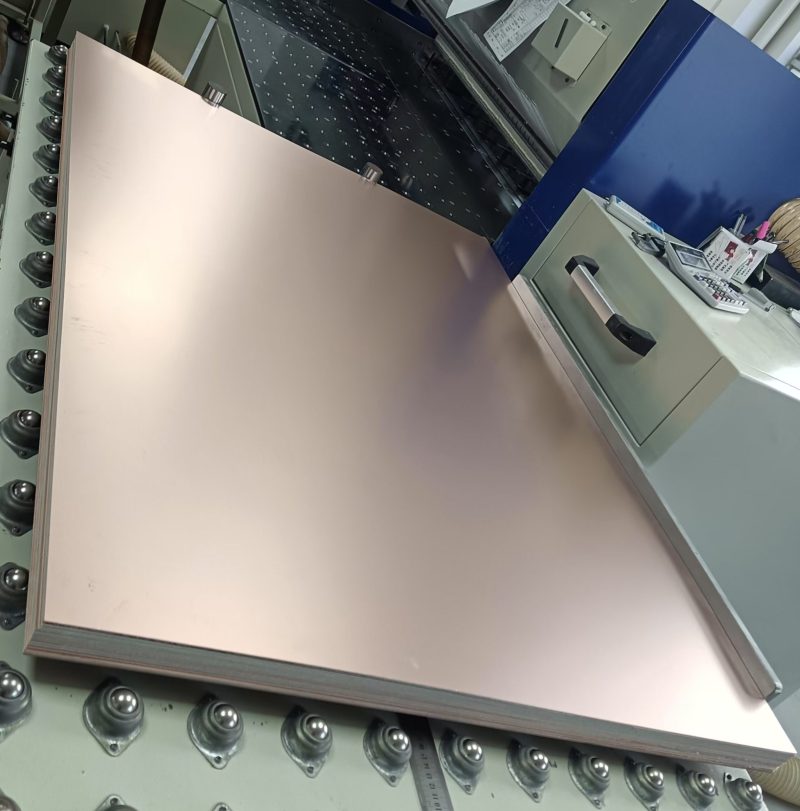

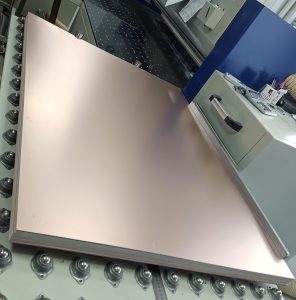

Aluminum PCBs are designed specifically for applications that generate a significant amount of heat, such as LED lighting and power electronics. The primary benefit of using aluminum in PCB construction is its excellent heat dissipation properties. Unlike traditional PCBs, which use FR4 or other insulating materials, aluminum PCBs incorporate a metal-based core, which helps to rapidly transfer heat away from sensitive components, preventing overheating and improving overall performance.

What’s the real story? Aluminum PCBs are becoming more common in high-power applications, where thermal management is critical. Whether it’s for LED light bulbs or power converters, aluminum PCBs offer a reliable solution for managing heat in high-performance environments.

| Aluminum PCB Benefits | Description |

|---|---|

| Heat Dissipation | Excellent at managing heat in high-power applications |

| Durability | Offers better thermal and mechanical stability |

| Applications | Commonly used in LED lighting and power electronics |

Rogers PCB materials are known for their superior performance in high-frequency and high-speed applications. These materials are engineered to minimize signal loss and maintain integrity at high frequencies, which makes them ideal for applications like telecommunications, aerospace, and defense. Rogers PCBs are designed with low dielectric loss and stable electrical properties, which ensure consistent performance even in challenging environments.

Ready for the good part? Rogers PCBs are not just about low signal loss; they are also optimized for high-frequency signals, making them the go-to choice for advanced electronics that require reliable performance under demanding conditions.

| Rogers PCB Features | Applications |

|---|---|

| Low Signal Loss | Ideal for high-frequency applications like telecommunications |

| Stable Electrical Properties | Ensures consistent performance in extreme environments |

| High-Performance | Used in aerospace, defense, and high-tech industries |

Ceramic PCBs are used primarily in high-temperature environments, where traditional PCB materials would fail. Made from a ceramic substrate with metal traces, these PCBs offer excellent thermal conductivity and electrical insulation. Ceramic PCBs are often used in automotive, military, and aerospace applications where performance and reliability under high thermal stress are paramount.

What’s the real story? Ceramic PCBs are highly specialized and provide a unique solution for applications that require both electrical insulation and heat resistance. They can withstand extremely high temperatures, making them invaluable in mission-critical systems.

| Ceramic PCB Features | Benefits |

|---|---|

| Thermal Conductivity | Excellent at transferring heat away from components |

| Electrical Insulation | Provides reliable electrical insulation under high temperatures |

| Applications | Common in aerospace, automotive, and military systems |

Q1: What is FR4?

A1: FR4 is a widely used PCB material made from fiberglass and epoxy resin. It provides excellent electrical insulation and is suitable for a variety of applications.

Q2: How is CEM3 different from CEM1?

A2: CEM3 offers better mechanical strength and is used for more complex designs than CEM1, which is typically used for simpler, single-sided PCBs.

Q3: Why is polyimide ideal for flexible PCBs?

A3: Polyimide is chosen for flexible PCBs due to its high thermal stability, flexibility, and ability to withstand environmental stress, making it perfect for wearable electronics.

Q4: What are the advantages of using aluminum PCBs?

A4: Aluminum PCBs are excellent at dissipating heat, making them ideal for high-power applications like LED lighting and power electronics.

Q5: How does Rogers PCB material perform in high-frequency applications?

A5: Rogers PCB materials minimize signal loss and maintain electrical integrity, making them ideal for high-frequency applications such as telecommunications and aerospace.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote