Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

Express PCB: The Ultimate Guide to Fast and Reliable PCB Solutions

If you’re navigating the fast-paced world of electronics, you’ve probably heard about express PCB. But what’s the real story? Express PCB has become a vital service for manufacturers and engineers who need circuit boards fast. With product life cycles getting shorter and competition intensifying, having the ability to go from concept to prototype in days is a game-changer. This article will walk you through everything you need to know about express PCB—from its importance and history to its application and the latest industry trends. Whether you’re an OEM, an electronics manufacturer, or a B2B buyer, this comprehensive guide will help you understand express PCB solutions and how to leverage them for maximum business impact. Ready for the good part? Let’s dive in.

Express PCB

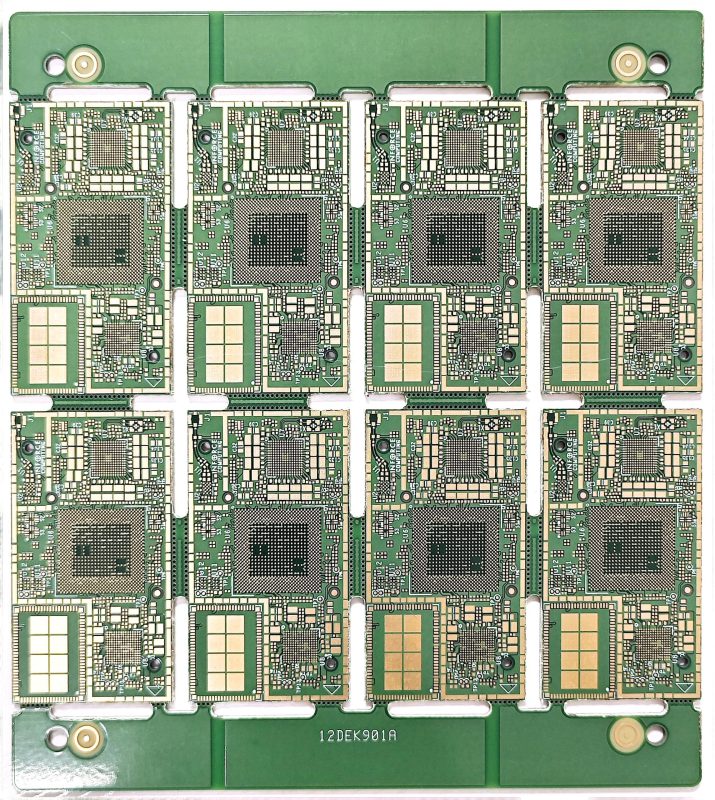

What’s under the hood of express PCB manufacturing? Here’s where it gets interesting—express PCB utilizes advanced production lines, automated quoting, and real-time order tracking. Unlike traditional PCB manufacturing, which can take weeks, express PCB cuts lead times down to just days or even hours. Here’s the kicker: express PCB companies use dedicated rapid-turn equipment and streamlined workflows to bypass bottlenecks. For example, a client needing a prototype for a new IoT device can submit a Gerber file, receive an instant quote, and see production begin in minutes. Let’s not forget the critical steps: quick file checks, optimized panelization, and parallel processing across multiple shifts. Express PCB is all about speed, but never at the expense of quality. In fact, modern express PCB lines are packed with inline AOI systems and real-time process controls. Companies like Shuoqiang Circuit have built their reputation on delivering not just quickly, but with the reliability that B2B clients demand. So, what’s the result? Consistent, high-quality boards that are delivered on time, every time.

| Parameter | Express PCB | Traditional PCB |

|---|---|---|

| Turnaround Time | 1-3 days | 7-21 days |

| Production Workflow | Streamlined | Multi-step |

| File Review | Automated/Instant | Manual |

| Quality Control | Inline/Automated | Final Stage |

| Minimum Order Quantity | 1+ | 5+ |

| Suitability | Prototypes, Urgent | Mass Production |

| Pricing | Premium | Standard |

Why are so many companies making the switch to express PCB? Here’s the scoop: speed is only the beginning. Express PCB services dramatically reduce time-to-market, giving you a powerful edge in competitive industries. But here’s the kicker: they’re also cost-effective, especially for prototyping and low-volume runs. Imagine an R&D team needing a quick spin on a new controller board—express PCB allows them to iterate fast, catch design flaws, and accelerate development cycles. And there’s more: express PCB provides incredible flexibility. Need last-minute changes? No problem. Express PCB suppliers are set up to accommodate urgent revisions and can handle everything from quick-turn prototypes to short-run production without missing a beat. For example, a European automotive supplier shaved weeks off their development schedule by using express PCB for their EV platform testing. The real-world impact? Faster design validation, fewer project delays, and improved innovation pipelines. And for B2B clients, that’s not just good business—it’s essential for survival.

| Benefit | Description | Example Use Case |

|---|---|---|

| Fast Turnaround | Boards delivered in 1-3 days | IoT prototyping |

| Design Flexibility | Easy design modifications and iterations | Medical device R&D |

| Cost-Effective | Ideal for prototypes and low-volume production | Consumer electronics |

| Enhanced Reliability | Inline testing and real-time quality controls | Automotive systems |

| Competitive Edge | Reduced time-to-market boosts business competitiveness | Startups & OEMs |

So, what types of express PCB services can you expect? The answer is: more than you might think. Express PCB isn’t just for simple boards—today’s services support a full range of PCB types, from basic single-sided to complex multilayer, flex, rigid-flex, and even high-density interconnect (HDI) boards. But here’s where it gets interesting: leading providers can deliver multilayer prototypes with blind/buried vias or impedance control in days. Want an aluminum-backed LED board in a rush? Express PCB has you covered. Specialized services might also include SMT assembly, stencil cutting, or component sourcing as part of a one-stop solution. For example, a robotics company recently ordered both four-layer rigid-flex boards and standard FR4 prototypes for simultaneous delivery to different departments. The flexibility is remarkable. Ready for the best part? Many suppliers now allow you to combine different PCB types within a single express order, making the process even more efficient and cost-effective.

| PCB Type | Features | Typical Applications |

|---|---|---|

| Single-Sided | Simple, fast, low-cost | Power supplies, toys |

| Double-Sided | More complex circuits | IoT devices, consumer goods |

| Multilayer | High layer count, compact | Servers, industrial controls |

| Flex/Rigid-Flex | Bendable, space-saving | Wearables, automotive |

| HDI | High density, microvias | Smartphones, tablets |

| Aluminum PCB | Heat dissipation | LED lighting, power modules |

Let’s talk materials—because they make all the difference in express PCB. The backbone is FR4, but express PCB services offer a variety of substrate options depending on your requirements. What’s the real story? Top suppliers maintain a stock of high-quality materials for rapid access: FR4, aluminum, polyimide, Rogers, and more. Copper thickness matters, too—express PCB can accommodate everything from standard 1oz to heavy copper for power electronics. Don’t forget surface finishes: HASL, ENIG, OSP, and silver are commonly available, even for rush jobs. But here’s the kicker: the choice of materials directly impacts performance, cost, and speed. For example, a telecom OEM using Rogers substrate for RF boards relies on express PCB to minimize dielectric loss and maximize signal integrity. Express PCB companies invest in robust inventory and quality assurance systems, ensuring that the right materials are always on hand—no matter how urgent the order.

| Material | Description | Use Case | Turnaround Time |

|---|---|---|---|

| FR4 | Standard, reliable | General electronics | 1-3 days |

| Aluminum | High thermal transfer | LED, power modules | 2-4 days |

| Polyimide | Flexible circuits | Wearables, flex PCBs | 2-5 days |

| Rogers | High-frequency | RF, telecom | 3-5 days |

| Heavy Copper | High current | Power supply | 3-6 days |

Ready to get the best results from express PCB? Here’s where careful design pays off. Start with the right file format—Gerber, ODB++, and Altium files are the industry standard. But here’s the kicker: express PCB thrives on “design for manufacturability” (DFM). Keep your design clear, avoid unnecessary complexity, and stick to recommended trace widths and spacing. Want to speed up processing? Use standard board sizes and avoid exotic stackups. What’s more, many suppliers offer free DFM checks to flag potential issues before production begins. For example, an embedded system engineer reduced lead time by 40% simply by using the express PCB supplier’s DFM checklist before submission. And don’t overlook documentation: clear BOMs, drill files, and fabrication notes help prevent costly delays. So, what’s the secret? Collaborate early with your express PCB supplier, take advantage of their design support, and keep communication lines open throughout the process.

| Design Tip | Benefit |

|---|---|

| Use Standard Formats | Faster processing, fewer errors |

| Follow DFM Practices | Improved manufacturability, speed |

| Keep Designs Simple | Reduced lead time, lower costs |

| Document Thoroughly | Prevents miscommunication, rework |

| Review with Supplier | Early issue detection, better results |

Selecting your express PCB partner is a strategic decision. But how do you separate the best from the rest? Start by evaluating experience and technical capability—does the supplier have a track record of meeting tight deadlines for complex boards? Here’s where it gets interesting: check certifications (ISO, UL, RoHS), customer testimonials, and after-sales support. What’s the real story? Communication is key. Leading suppliers offer direct engineer access, rapid feedback on queries, and transparent order tracking. Consider a real-world example: an industrial automation firm saved thousands by switching to a supplier with dedicated process engineers who proactively resolved Gerber issues. Price matters, but don’t be fooled by rock-bottom quotes that sacrifice quality or reliability. Ready for the good part? The best express PCB suppliers act as partners—sharing design insights, offering flexible pricing, and scaling production as your business grows.

| Criteria | Why It Matters | Example |

|---|---|---|

| Certifications | Quality assurance, compliance | ISO9001, UL |

| Technical Support | Fast troubleshooting, design help | Direct engineer access |

| Lead Time Guarantee | Meet deadlines, reduce risk | 1-3 day turnaround |

| Communication | Smooth process, fewer mistakes | Instant messaging |

| Pricing Transparency | Avoid hidden costs | Clear online quotes |

Ordering express PCB should be as easy as a few clicks—and with modern platforms, it is. But here’s where it gets interesting: leading suppliers provide instant online quoting tools. Upload your Gerber files, select your specs, and get a price within seconds. Need a custom stackup or non-standard finish? Many systems allow for advanced options without slowing you down. What’s the real story? After quoting, ordering is seamless—just confirm the order, select shipping, and choose a payment method. Some suppliers even offer automated design rule checks before you pay, catching errors upfront. For example, a Canadian medical device company used an express PCB platform to order five separate prototypes in under 20 minutes—tracking every stage online. Ready for the good part? Real-time order tracking and proactive email updates keep you informed, so you never have to wonder where your boards are.

| Step | Action Required | Typical Timeframe |

|---|---|---|

| Instant Quoting | Upload files, select specs | <1 minute |

| Automated DRC/DFM | System checks for errors | <5 minutes |

| Order Confirmation | Confirm specs, shipping, payment | <5 minutes |

| Production Start | Board goes into fabrication | Immediate |

| Real-Time Tracking | Monitor every production stage | Throughout order cycle |

When should you use express PCB for prototyping? The answer is simple: whenever speed matters. Express PCB is a prototyping powerhouse, enabling engineers and product teams to validate new designs quickly and cost-effectively. Here’s the kicker: it’s not just about getting a board—it’s about building, testing, and refining ideas before committing to volume production. For example, an American wearable tech startup went from concept to first working prototype in under 72 hours using express PCB. Ready for the good part? Multiple prototype iterations can be completed in a single week, slashing months off development timelines. And with low minimum order quantities, you can afford to experiment—try three variations, test them all, and choose the winner. What’s more, most express PCB suppliers also offer SMT assembly services for prototypes, further accelerating your time-to-market.

| Advantage | Impact | Real-World Example |

|---|---|---|

| Speed | Rapid design validation | Wearable tech prototyping |

| Flexibility | Easy to revise, test multiple ideas | Consumer electronics R&D |

| Low MOQs | Affordable experimentation | Startups, universities |

| Assembly Support | Complete functional prototypes fast | IoT device launches |

| Cost Savings | Minimized wasted development | Automotive platform design |

Here’s where express-PCB really shines—production capabilities have evolved far beyond basic prototypes. Today’s express-PCB suppliers support everything from small runs of custom boards to medium-volume production. What’s the real story? Minimum order quantities can be as low as one, while maximum batch sizes often reach several hundred boards per run. Want panelization for better assembly? Express PCB platforms let you set up multi-design panels and even add stencil orders for SMT. Lead times remain impressively short—even for multilayer or specialty PCBs. For example, an Indian e-commerce firm regularly orders 100+ two-layer boards with assembly, delivered in three days. But here’s the kicker: express-PCB production uses advanced scheduling and process controls to maximize efficiency without sacrificing quality. This capability is a game-changer for businesses with tight launch schedules or rapidly changing product requirements.

| Option | Description | Lead Time | MOQ |

|---|---|---|---|

| Single PCB | Individual boards | 1-2 days | 1 |

| Batch Production | Small/medium runs | 2-4 days | 5-500 |

| Panelization | Multiple designs on one panel | 2-4 days | 5+ |

| Assembly (SMT/THT) | Components added to boards | 3-7 days | 1+ |

| Specialty Boards | HDI, flex, etc. | 3-7 days | 1+ |

Here’s a fact: speed is worthless without quality. Express-PCB suppliers have invested heavily in automated optical inspection (AOI), flying probe testing, and in-line electrical tests to guarantee reliability—even under the tightest deadlines. But here’s where it gets interesting: these quality checks happen in real time, not just at the end of production. Inline process monitoring, SPC data collection, and digital traceability are standard. For instance, a European medical device OEM reported a 50% reduction in field failures after switching to a supplier with advanced QA systems. Ready for the good part? Express PCB partners provide certificates of conformity, test reports, and traceable batch records—so you can meet regulatory requirements and customer expectations with ease.

| Test Type | Purpose | Typical Application |

|---|---|---|

| Automated Optical | Solder mask, silkscreen inspection | All PCB types |

| Flying Probe | Electrical connectivity verification | Prototypes, low volume |

| ICT (In-Circuit) | Functional/component testing | Volume production |

| X-ray Inspection | BGA, hidden solder joint checks | HDI, complex boards |

| Final Visual | Final appearance, label verification | All PCB types |

Here’s the million-dollar question: what drives express-PCB pricing? It’s all about balancing speed, complexity, and order size. Express PCB typically comes at a premium—after all, you’re paying for priority access to machines, skilled labor, and top-tier materials. But here’s the kicker: costs are transparent, with online tools breaking down every component—material, processing, finish, and shipping. For example, a Japanese robotics firm analyzed costs across five suppliers and found express PCB saved money overall by reducing design errors and time-to-market. What’s more, you can save by optimizing designs (simple stackups, standard sizes), ordering in logical batches, or choosing cost-effective finishes. Don’t overlook hidden savings, either—fewer field failures and less rework can more than offset upfront price differences. Bottom line: express-PCB offers real value for money, especially in high-stakes, fast-moving markets.

| Factor | Influence on Price | Cost Control Tip |

|---|---|---|

| Turnaround Time | Faster = higher cost | Plan ahead when possible |

| Board Complexity | Layers, vias, special materials | Use standard features |

| Order Volume | Larger runs = lower per-unit cost | Batch orders if possible |

| Surface Finish | ENIG, OSP, HASL, etc. | Choose finishes wisely |

| Testing Requirements | AOI, flying probe, ICT | Standard tests suffice for many |

Express-PCB isn’t just for one industry—it’s everywhere innovation happens. Here’s the kicker: from medical devices and automotive ECUs to industrial controls and consumer electronics, express-PCB helps companies get products to market ahead of the competition. Take, for example, a German industrial automation company that accelerated development cycles with quick-turn boards for sensor modules. In consumer tech, express PCB enables rapid prototyping for smart home devices, wearables, and gaming accessories. And let’s not forget critical industries: express PCB is used for patient monitors, diagnostic devices, and even aerospace test systems, where speed and reliability are non-negotiable. Ready for the good part? As businesses pivot to digital and IoT solutions, the role of express PCB is only growing. No matter your sector, fast, flexible PCB supply can make or break your next product launch.

| Industry | Express PCB Uses | Example Products |

|---|---|---|

| Consumer Electronics | Prototypes, pilot runs | Smart wearables, gadgets |

| Industrial | Control boards, sensor modules | Robotics, automation |

| Medical | Diagnostic, monitoring devices | ECG, portable analyzers |

| Automotive | ECUs, BMS, display modules | EVs, ADAS, dashboard |

| Aerospace | Avionics test systems, sensors | Test rigs, satellite boards |

Let’s be honest—things don’t always go as planned. But here’s the good news: express PCB suppliers excel at fast troubleshooting and resolution. What’s the real story? Common issues include file mismatches, panelization errors, or unexpected design changes mid-production. But don’t worry—most express PCB partners provide dedicated support lines, online chat, and instant engineering feedback. For example, a

Russian e-mobility startup resolved a critical Gerber error in under an hour, thanks to proactive supplier support. Here’s where it gets interesting: many platforms allow you to pause, revise, or even cancel orders before fabrication starts—minimizing losses. Best practices? Always double-check files, keep communication lines open, and partner with suppliers who value transparency. Ready for the good part? With the right express-PCB partner, even the occasional hiccup becomes a valuable learning experience.

| Issue | Root Cause | Resolution Approach |

|---|---|---|

| File Format Error | Unsupported or corrupt files | Use recommended formats |

| Panelization Problems | Incorrect outline or design setup | Use supplier’s templates |

| Design Change Mid-Order | Late revisions | Communicate ASAP |

| Shipping Delays | Courier or customs issues | Choose reliable shipping |

| Quality Defects | Process or material errors | Comprehensive QA/testing |

What does the future hold for express-PCB? Here’s where it gets exciting: the industry is embracing automation, AI, and digital twins to boost speed, reduce errors, and enable “smart” production. What’s the real story? On-demand PCB manufacturing—think same-day production, direct-to-fab IoT interfaces, and AI-driven DFM feedback—will become standard. Sustainability is also taking center stage, with eco-friendly materials, closed-loop recycling, and energy-efficient factories leading the way. For example, global brands now demand carbon footprint tracking and green PCB options even for rapid-turn orders. Ready for the good part? As 5G, automotive electronics, and smart medical devices grow, express-PCB providers are investing in even more flexible capabilities—shorter runs, more board types, and seamless integration with digital product design tools. The future? Faster, smarter, greener, and more collaborative.

| Trend | Description | Expected Impact |

|---|---|---|

| Automation/AI | Smart scheduling, instant feedback | Shorter cycles, fewer errors |

| Digital Integration | Cloud, IoT, design software links | Seamless process |

| Sustainability | Green materials, energy efficiency | Eco-friendly products |

| Product Customization | More board types, flexible runs | Broader market access |

| Globalization | Multi-region fast delivery | Wider reach, more options |

Let’s wrap it up. Express-PCB has transformed the way companies design, prototype, and launch electronic products. From lightning-fast turnaround times and unparalleled flexibility to advanced quality assurance and broad material options, express PCB is no longer a luxury—it’s a necessity in today’s hyper-competitive markets. But here’s the kicker: the real value comes from choosing the right express PCB partner, optimizing your designs for manufacturability, and leveraging express services for everything from prototyping to full production. Whether you’re a startup, an OEM, or a global manufacturer, the ability to iterate quickly and deliver quality products on schedule can set you apart from the competition. As technology continues to evolve, expect express PCB solutions to become even more integral to your success. The future is fast—don’t get left behind.

Q1: What is express-PCB?

Express PCB refers to printed circuit board manufacturing services that provide fast, efficient turnaround times, ideal for rapid prototyping and urgent production needs.

Q2: How does express-PCB manufacturing work?

Express PCB manufacturing uses streamlined processes, advanced machinery, and dedicated workflows to deliver high-quality PCBs in much shorter timelines compared to standard production.

Q3: What are the main advantages of using express-PCB services?

The primary benefits include speed, flexibility, cost-effective prototyping, and support for tight project deadlines.

Q4: Can express-PCB services handle complex or multilayer designs?

Yes, many express-PCB providers can fabricate complex, multilayer, and even specialized boards like HDI or rigid-flex, though costs and lead times may vary.

Q5: How do I select the best express-PCB supplier for my project?

Evaluate suppliers based on speed, quality, communication, certifications, customer reviews, and the ability to handle your specific design requirements.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote