10. Material Choices for High-Frequency PCBs

Let’s turn up the speed—literally.

High-frequency applications, especially in telecom and RF, demand specialized materials that minimize signal loss and ensure signal integrity. But what’s the real story? Standard FR4 just doesn’t cut it when GHz speeds are involved.

Instead, you’ll find materials like:

● Rogers laminates: These offer low dielectric loss and tight Dk tolerances, ideal for RF and microwave circuits.

● Teflon (PTFE): Has outstanding electrical properties and is often used for satellite, radar, and aerospace boards.

● Ceramic composites: Provide exceptional heat resistance and are used in military and space-grade systems.

Three practical examples:

-

A 5G antenna board made with Rogers 4003C to reduce insertion loss at 3.5GHz.

-

A satellite communication board using PTFE to maintain signal integrity over long distances.

-

An industrial IoT gateway using a ceramic hybrid laminate to manage thermal loads and EMI.

| High-Frequency Material | Dielectric Constant (Dk) | Best Use Cases |

|---|---|---|

| Rogers 4003C | 3.55 | 5G, automotive radar |

| Teflon (PTFE) | ~2.1–2.5 | Aerospace, RF devices |

| Ceramic Hybrid | ~6.5–10+ | High-temp, military |

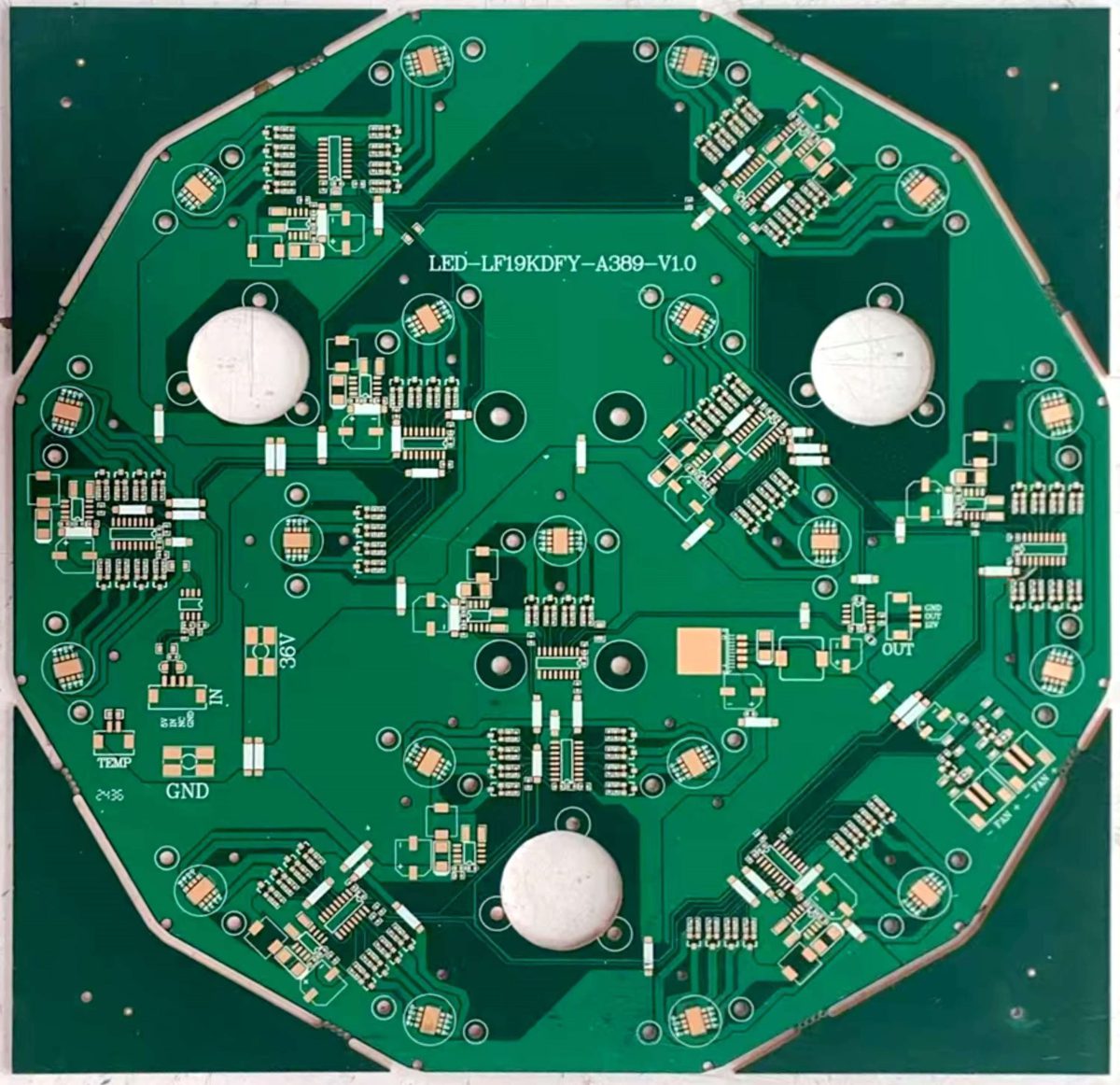

11. Thermal Management Materials

Now it’s getting hot—literally.

Thermal performance is mission-critical in power electronics, LED lighting, automotive ECUs, and high-speed data systems. But here’s the kicker… without proper materials, PCBs can warp, degrade, or even fail catastrophically under thermal stress.

Enter thermal management solutions:

● Aluminum-core PCBs: Combine a thermally conductive core with traditional copper to efficiently spread heat away from components.

● Thermal vias: Copper-plated through-holes connecting layers that conduct heat vertically toward heatsinks or external chassis.

● Ceramic PCBs: Offer unmatched thermal conductivity and are ideal for high-power, high-density modules.

Three use cases:

-

An LED floodlight uses an aluminum-backed PCB to maintain light output consistency and lifespan.

-

An EV battery monitoring system employs thermal vias to disperse heat from the BMS ICs.

-

A server-grade VRM (voltage regulator module) includes ceramic-filled prepreg to reduce hotspots.

| Thermal Material Type | Thermal Conductivity (W/mK) | Common Use |

|---|---|---|

| Aluminum Core | ~1–5 | LEDs, power supplies |

| Thermal Vias | Variable | BGA, MOSFETs, processors |

| Ceramic Substrate | ~20–200 | RF amplifiers, power ICs |

12. Environmental and RoHS-Compliant Materials

It’s time to get green—literally and legally.

The electronics industry is under increasing pressure to eliminate hazardous materials. That means your PCB materials must now comply with standards like RoHS, REACH, and WEEE. But here’s where it gets interesting… compliance is about more than ticking boxes—it’s about futureproofing your brand.

Key considerations:

● Halogen-Free Laminates: Reduce smoke and toxicity during combustion, especially in consumer and public-space devices.

● Lead-Free Finishes: ENIG and lead-free HASL are now preferred over traditional SnPb HASL in most regions.

● Low-VOC Solder Masks: Some eco-conscious manufacturers are switching to environmentally safe curing agents and resins.

Examples of compliant applications:

-

A children’s toy PCB uses halogen-free FR4 and OSP finish to meet EU RoHS requirements.

-

A telecom server motherboard features REACH-compliant epoxy and ENIG finish for global shipment.

-

A smart home device manufacturer requires UL94-V0 halogen-free material for all PCB enclosures.

| Compliance Type | Banned/Regulated Elements | Material Alternatives |

|---|---|---|

| RoHS | Pb, Hg, Cd, Cr6+, PBB, PBDE | Lead-free HASL, halogen-free FR4 |

| REACH | SVHC (Substances of Very High Concern) | Low-toxicity resins |

| WEEE | Product recyclability | Modular PCB design |

13. Specialty Materials for Unique Applications

Sometimes, standard materials just won’t do.

Special applications demand special materials—and printed circuit boards can be tailored for extreme conditions, high complexity, or unusual form factors. Ready for the good part?

● HDI PCBs: Use microvias, stacked vias, and ultra-thin prepregs for compact designs like smartphones, tablets, and wearable tech.

● Rigid-Flex Materials: Combine rigid FR4 sections with flexible polyimide tails for dynamic applications like medical catheters or aerospace panels.

● Space/Aero-Grade Materials: Use low-outgassing compounds, thermally stable resins, and advanced laminates like Teflon-glass composites.

Three practical examples:

-

A defense drone control PCB integrates rigid-flex with polyimide and stacked microvias.

-

A high-speed digital camera uses HDI material to support its dense 20-layer FPGA board.

-

A Mars rover PCB uses space-grade laminate that resists extreme UV and vacuum conditions.

| Specialty PCB Type | Key Material Used | Application |

|---|---|---|

| HDI PCB | Laser-drilled vias, thin cores | Smartphones, wearables |

| Rigid-Flex PCB | FR4 + Polyimide | Aerospace, surgical tools |

| Aerospace/Military | Low outgassing epoxy/glass | Satellites, aircraft |

14. Impact of Material Selection on PCB Cost

Let’s talk numbers—what does it all cost?

Material selection is the number one cost variable in PCB manufacturing. But here’s the kicker… the cheapest material isn’t always the most cost-effective. Poor choices can lead to field failures, redesigns, and lost customer trust.

Main cost influencers:

● Base Material: FR4 is the most affordable. Rogers, polyimide, and ceramics are more expensive but offer superior performance.

● Copper Weight: Thicker copper costs more per square inch. High-power designs will increase copper demand significantly.

● Surface Finish: HASL is cheap, ENIG is premium. The choice affects both cost and assembly success.

● Layer Count: Each added layer requires extra dielectric and copper, increasing both material and processing time.

| Material Factor | Low-Cost Option | Premium Option | % Cost Difference |

|---|---|---|---|

| Substrate | FR4 | Rogers, ceramic | +30–200% |

| Finish | HASL | ENIG, immersion Ag | +20–60% |

| Copper Weight | 1 oz | 3–4 oz | +25–50% |

| Layers | 2 | 8–12 | +100–300% |

15. Summary of PCB Material Layers and Their Role

Let’s wrap it all up with a bow.

Every layer in a printed circuit board plays a role—mechanical, electrical, thermal, or visual. From the substrate that forms its skeleton to the silkscreen that communicates its identity, understanding what a PCB is made of empowers you to design smarter, source better, and manufacture more reliably.

Remember: the ideal mix of materials depends on your product’s demands. There’s no one-size-fits-all approach, but with this breakdown, you can speak confidently with engineers, suppliers, and clients alike.

Use this as your cheat sheet during sourcing conversations or technical meetings—it’s the foundation for building exceptional, cost-effective, and compliant PCBs.

| PCB Layer | Function | Common Materials |

|---|---|---|

| Substrate | Mechanical foundation | FR4, polyimide, ceramic |

| Copper Layer | Signal and power paths | 0.5–6 oz copper foil |

| Dielectric | Electrical insulation | Epoxy, PTFE, ceramic |

| Solder Mask | Oxidation and bridging protection | LPI epoxy mask |

| Silkscreen | Component guidance | White/black epoxy ink |

| Surface Finish | Solderability and longevity | ENIG, HASL, OSP |

FAQ Section

-

Q1: What is PCB made of?

A PCB is made of layers including a non-conductive substrate (like FR4), copper foil, a solder mask layer, silkscreen markings, and sometimes a surface finish like ENIG or HASL. -

Q2: How does the substrate material affect a PCB?

The substrate determines the board’s strength, flexibility, heat resistance, and dielectric properties, influencing overall performance and application suitability. -

Q3: What is the purpose of the solder mask in a PCB?

The solder mask protects copper traces from oxidation, prevents solder bridging during assembly, and gives the PCB its color (usually green). -

Q4: Why are there different surface finishes on PCBs?

Surface finishes like ENIG, HASL, or OSP protect copper pads and improve solderability, with each type suiting different assembly and storage needs. -

Q5: Are PCBs environmentally friendly?

Modern PCBs can be made with RoHS- and REACH-compliant materials, using halogen-free laminates and lead-free finishes to reduce environmental impact.

Well-known PCB supplier

Well-known PCB supplier

Quote

Quote