Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

Blank PCB—the foundation for every electronics project—plays a critical role for engineers, buyers, and innovators. If you’re struggling to prototype or manufacture new designs, the blank PCB is where your solution starts. But here’s the kicker… it’s not just an empty board. It’s the first step in transforming a schematic into a tangible product, making it vital for rapid prototyping, R&D, and custom projects.

Blank PCBs serve:

Engineers testing circuit ideas

Students learning soldering

Makers building custom gadgets

Choosing the right blank PCB can make or break your prototype or first production run. Their structure, finish, and size directly impact assembly, reliability, and cost.

| WHAT IS A BLANK PCB? | KEY FEATURES | TYPICAL USERS |

|---|---|---|

| Definition | Unpopulated, copper-clad board | Engineers, students, hobbyists |

| Core Purpose | Prototyping, assembly foundation | R&D, education, DIY |

| Role | Start point for design | New product, learning |

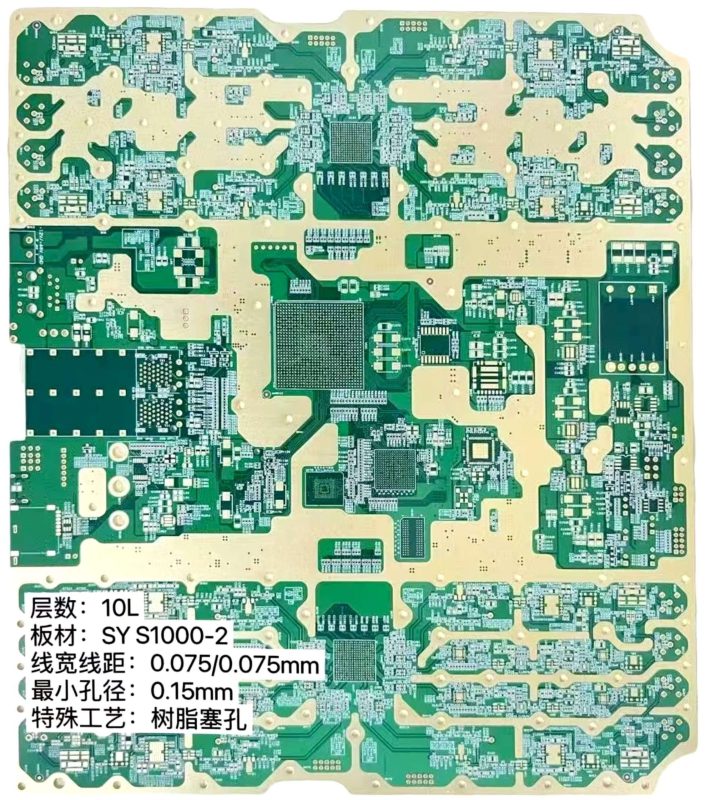

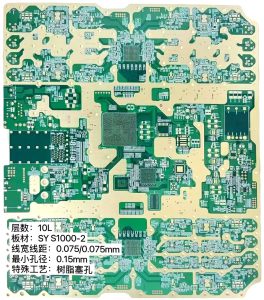

Blank PCB

Blank PCB production is a blend of chemistry, precision engineering, and quality control. Ready for the good part? It starts with large copper-clad laminate panels. These are cleaned, coated with photoresist, exposed to light, and etched to create precise patterns. CNC or laser drills make holes, then cleaning and AOI inspection catch defects.

Factories:

Use automated lines for volume production

Employ manual steps for specialty or small-batch jobs

Add anti-oxidation or OSP finishes to protect copper

Quality checks throughout keep scrap low and performance high.

| MANUFACTURING STEP | DESCRIPTION | QUALITY CONTROL |

|---|---|---|

| Photoimaging | Pattern transfer | Visual, AOI |

| Etching | Removes copper | Thickness check |

| Drilling | Holes/vias | Hole accuracy |

| Finishing | Protective coat | Solderability, cleanliness |

Blank PCBs can be made from a variety of materials—each with unique performance and price. What’s the real story? FR-4 is the standard for most electronics due to flame resistance and mechanical strength. CEM-1/CEM-3 provide cheaper alternatives for simple devices. Polyimide enables flexibility and temperature endurance. Aluminum core boards help dissipate heat.

Typical choices:

FR-4 for consumer and industrial electronics

CEM-1 for basic toys or gadgets

Aluminum for LED lighting and power boards

| MATERIAL | ADVANTAGE | COMMON USE |

|---|---|---|

| FR-4 | Strong, flameproof | Appliances, routers |

| CEM-1 | Low-cost | Entry gadgets |

| Polyimide | Flexible, high temp | Aerospace, wearables |

| Aluminum | Heat dissipation | LED, power |

Not all blank PCBs are the same. This is where it gets interesting… Single-sided blank PCBs have copper on one face for basic circuits. Double-sided boards support complex layouts with two copper layers. Multilayer boards offer higher performance by stacking multiple layers for signal routing and ground planes. Flexible and rigid-flex boards support wearables and complex assemblies.

| PCB TYPE | LAYER COUNT | USE CASES |

|---|---|---|

| Single-sided | 1 | Toys, calculators |

| Double-sided | 2 | Power controls |

| Multilayer | 4+ | Telecom, servers |

| Flexible | 1-6 | Sensors, wearables |

| Rigid-flex | 2-20 | Robotics, aerospace |

Sizing your blank PCB right saves cost and reduces waste. But here’s the kicker… Standard sizes make for cheap, efficient production, but custom shapes and thicknesses are available for special needs.

Panel sizes: 18”x24”, 12”x18” (or custom)

Thickness: 0.6mm to 2.4mm

Copper: 0.5oz to 3oz

When ordering, specify:

Material

Board thickness

Copper weight

Number of layers

Finish

Drill patterns

| PARAMETER | OPTIONS | DESIGN IMPACT |

|---|---|---|

| Size | Std/custom | Fit, waste, cost |

| Thickness | 0.6–2.4mm | Strength, flexibility |

| Copper | 0.5–3oz | Current, heat |

| Finish | HASL, OSP | Assembly, shelf |

Blank PCBs are everywhere in innovation and education. Ready for the good part? Their top uses include prototyping, STEM education, and hobby electronics.

Engineers quickly build and iterate on prototypes

Educators teach soldering and circuit basics

Makers hack, repair, and experiment

| APPLICATION | SECTOR | BENEFIT |

|---|---|---|

| Prototyping | Engineering | Fast iteration |

| Education | Schools | Hands-on learning |

| Maker/DIY | Home | Custom builds |

Blank PCBs aren’t “one size fits all.” What’s the real story? Always choose based on electrical, environmental, and assembly needs.

Select material for strength, heat, or cost

Choose copper weight for power handling

Pick size and finish for assembly process

Evaluate suppliers on quality, delivery, and service.

| FACTOR | WHY IT MATTERS | SELECTION TIP |

|---|---|---|

| Material | Durability | Match to use |

| Copper | Handles current | Don’t underspec |

| Supplier | Quality | Check reviews |

The blank PCB is just a starting point. But here’s the kicker… Add components and you get a finished “printed” PCB (PCBA).

Blank PCB: Only copper traces, no components

Printed PCB: Components soldered, ready to use

| ATTRIBUTE | BLANK PCB | PRINTED PCB |

|---|---|---|

| Components | None | Soldered |

| Purpose | Prototyping | Final product |

| Users | R&D, labs | End-user, OEM |

The surface finish of a blank PCB affects assembly, shelf life, and performance. Ready for the good part? The top choices are HASL, ENIG, and OSP.

HASL: Cheap, easy soldering, not for fine-pitch

ENIG: Flat, durable, top for high-end

OSP: Lead-free, for cost-sensitive projects

| FINISH | ADVANTAGE | BEST USE |

|---|---|---|

| HASL | Cheap, easy | Toys, appliances |

| ENIG | Flat, reliable | Telecom, servers |

| OSP | Eco-friendly | Consumer, DIY |

Damage in transit can ruin a whole order. But here’s the kicker… Proper packaging is vital.

Vacuum sealed, anti-static bags for bulk

Foam or sleeves for small runs

Custom crates for aerospace/medical

Best practices:

Label everything

Use desiccants for moisture

Edge protectors for shipping

| PACKAGING | BENEFIT | BEST FOR |

|---|---|---|

| Vacuum sealed | No dust/moisture | Factories |

| Foam/sleeve | Impact proof | Small batches |

| Custom crate | Traceability | Aerospace |

Certifications set reliable suppliers apart. What’s the real story? The main standards are IPC-6012 (fabrication), UL 94 V-0 (flammability), RoHS/REACH (environment), ISO 9001 (quality).

IPC-6012: Applies to all markets

UL 94 V-0: Needed for safety in consumer/industrial

RoHS/REACH: Required for global export

| CERTIFICATION | COVERAGE | REQUIRED FOR |

|---|---|---|

| IPC-6012 | Fab, test | Most electronics |

| UL 94 V-0 | Flammability | Consumer/industrial |

| RoHS | Environmental | Exports |

Blank PCB costs depend on size, material, layers, finish, and volume. But here’s the kicker… Small, simple boards cost pennies in bulk. Advanced or custom PCBs can cost dollars per unit.

Standard size, finish = low cost

More layers, premium finish = higher cost

Small quantities or rush = added price

| FACTOR | LOW-END | HIGH-END |

|---|---|---|

| Size | Small | Large, custom |

| Layers | 1 | 10+ |

| Finish | OSP | ENIG |

| Volume | 10 pcs | 10,000 pcs |

Improper storage kills solderability and causes corrosion. What’s the real story? Store in sealed bags, cool, and dry. Avoid dust, oils, and humidity.

Use gloves

Store flat to avoid warping

Rotate inventory

| STORAGE | WHY | RISK IF IGNORED |

|---|---|---|

| Low humidity | Prevents oxidation | Corrosion |

| Flat storage | Avoids warping | Bowing |

| Gloves | Avoids oils | Bad soldering |

Blank-PCBs let engineers test ideas fast. Ready for the good part? Use breadboards, hand soldering, or reflow for quick assembly.

Quick iteration

Supports SMT or through-hole

Great for STEM education

| TOOL | BENEFIT | USE CASE |

|---|---|---|

| Breadboard | Fast | Proof of concept |

| SMT adapter | Small builds | IoT, wearables |

| Manual soldering | Cheap | Student labs |

The blank PCB sector is evolving fast. This is where it gets interesting… New trends: eco-friendly substrates, direct-to-fab online ordering, miniaturization, and smarter logistics.

Greener materials (halogen-free, bio-resin)

Finer pitches, smaller boards

Online platforms for rapid quote and order

| TREND | MARKET IMPACT | CUSTOMER BENEFIT |

|---|---|---|

| Green materials | Meet regs | Access, value |

| Miniaturization | Wearables | Small devices |

| Online ordering | Fast turnaround | R&D, startups |

Blank-PCBs are the backbone of hardware development and rapid prototyping. Ready for the good part? Select the right type, finish, and supplier to streamline your design cycle and control costs. Always check quality, certifications, and storage conditions for best results. Blank PCBs enable creative engineering and fast progress from idea to product.

Q1: What is a blank-PCB?

A blank PCB is an unpopulated circuit board with copper traces, but no components.

Q2: How does blank-PCB manufacturing work?

Manufacturing covers photoimaging, etching, drilling, and surface finishing before any assembly.

Q3: What materials are used in blank-PCBs?

Common choices include FR-4, CEM-1, polyimide, and aluminum depending on application.

Q4: How should blank-PCBs be stored?

Keep in dry, anti-static packaging away from sunlight and humidity for best shelf life.

Q5: What impacts blank-PCB cost?

Main factors are board size, layers, finish, order volume, and material used.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote