Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

In the world of electronics, printed circuit boards (PCBs) are crucial components that help power and connect various devices. One of the most important types of PCBs is the blank PCB board, which forms the foundation for countless electronic devices. Understanding blank PCBs is essential for manufacturers, designers, and engineers looking to create high-quality, efficient electronic products. This article delves deep into blank PCB boards, covering everything from their definition and manufacturing process to their applications and the factors that influence their selection.

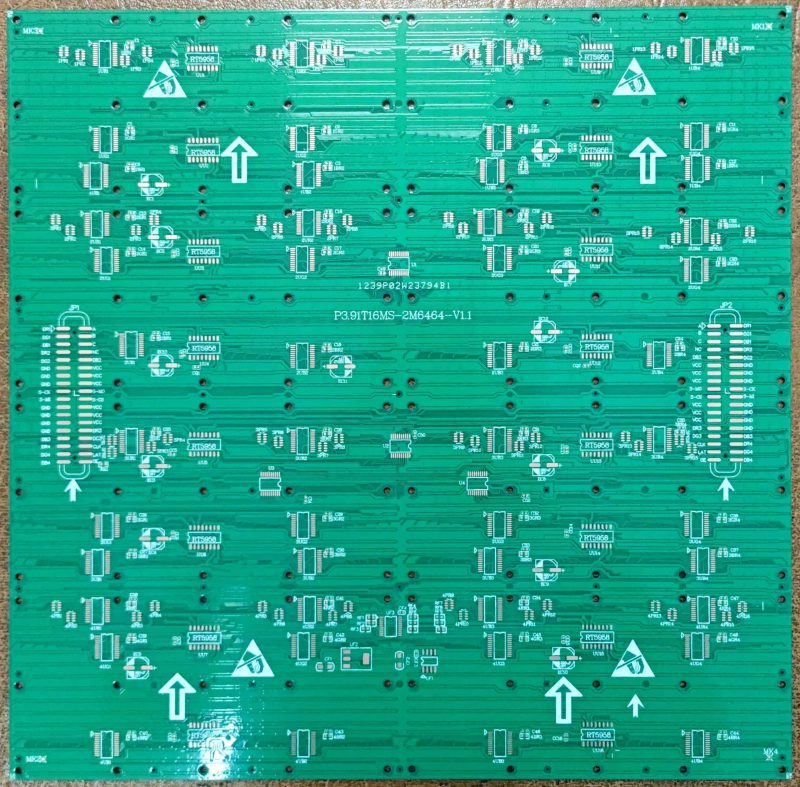

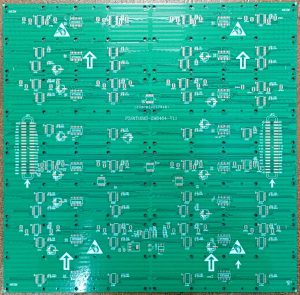

Blank PCB Boards

A blank PCB board is essentially a bare circuit board that has not yet been populated with electronic components. At its core, it consists of a substrate, typically made from materials like FR4, a copper layer, and various traces and pads that will eventually be used to connect the components. But here’s the kicker—this “blank” board is far from simple; it’s the start of a complex electronic assembly.

Blank PCBs come in various forms depending on the design and application, including single-layer, double-layer, and multi-layer boards. The core function of a blank PCB is to serve as the foundation for the electronic components that will be soldered onto it. These boards are manufactured to exacting standards to ensure the integrity of the components and the overall functionality of the finished electronic product.

What’s more, blank PCB boards come in various shapes and sizes, allowing for flexibility in design. They are typically used in a wide range of applications from consumer electronics to automotive systems, making them an integral part of modern technology.

| Feature of Blank PCB | Description |

|---|---|

| Substrate Material | Typically made from FR4, CEM1, or other materials. |

| Layers | Can be single-layer, double-layer, or multi-layer. |

| Function | Serves as the base for attaching electronic components. |

Blank PCBs are produced through a multi-step process that involves precision and quality control. First, the material for the substrate is selected, with FR4 being the most common choice due to its durability and electrical insulation properties. The substrate is then coated with a thin layer of copper, which will eventually form the traces on the PCB.

Once the substrate is prepared, the next step involves etching, where unwanted copper is removed to leave behind the traces that will carry the electrical signals. These traces are essential for connecting the various components that will later be soldered onto the board. The etching process is followed by drilling, which creates holes for components like resistors, capacitors, and connectors.

What’s the real story? The precision required at each step is crucial for the final functionality of the PCB. Small errors in the process can lead to defects that affect the performance of the entire circuit.

Finally, after drilling, the PCB undergoes a cleaning and surface finish process. The cleaned surface is then ready for the addition of components, completing the transition from a blank PCB to a fully functional circuit board.

| Manufacturing Step | Description |

|---|---|

| Substrate Preparation | Selection and preparation of the base material. |

| Copper Coating | Thin copper layer is added to the substrate. |

| Etching | Unwanted copper is removed to form electrical traces. |

| Drilling | Holes are drilled for components. |

When it comes to blank PCB boards, variety is key. These boards come in various configurations, each suited to different applications. The most common types are:

Single-sided PCBs: These are the simplest form of PCB, with all the components placed on one side of the board. Single-sided boards are often used in low-complexity applications.

Double-sided PCBs: These boards have traces on both sides, allowing for more complex designs. Double-sided PCBs are used in applications that require more connections but still maintain simplicity in design.

Multi-layer PCBs: Multi-layer PCBs consist of several layers of copper traces separated by insulating materials. These boards are used for high-density circuits that require many connections.

Flexible PCBs: These are made from flexible materials and can be bent or twisted into various shapes, making them ideal for compact or wearable devices.

Rigid-flex PCBs: Combining the features of both rigid and flexible PCBs, these are used in applications where space is limited, and both flexibility and durability are required.

This is where it gets interesting: each type of blank PCB offers distinct advantages depending on the specific requirements of the end product. For instance, multi-layer PCBs are more expensive but are necessary for advanced devices like smartphones and medical equipment.

| PCB Type | Characteristics | Application |

|---|---|---|

| Single-sided | Simple, one-sided traces | Basic consumer electronics |

| Double-sided | Traces on both sides | Moderate complexity designs |

| Multi-layer | Several layers of copper traces | High-density, advanced devices |

| Flexible | Made from flexible materials | Wearables, compact devices |

| Rigid-flex | Combines rigidity and flexibility | Space-constrained applications |

Blank PCBs are made from a variety of materials, each chosen for its specific properties. The most commonly used materials for blank PCBs are:

FR4: A fiberglass-based material that is the industry standard for most blank PCBs due to its strong insulation properties, durability, and low cost.

CEM1 and CEM3: These are composite materials often used for lower-cost, single-sided PCBs. They offer good electrical insulation and are lightweight.

Polyimide: Often used for flexible PCBs, polyimide provides both flexibility and thermal stability.

Aluminum: Used for heat dissipation in specific applications, such as LED PCBs, aluminum offers excellent thermal management properties.

Ready for the good part? The choice of material can significantly impact the performance and cost of the final product. For example, FR4 is typically chosen for its balance of price and performance, while aluminum is chosen when heat management is a critical factor.

| Material | Characteristics | Application |

|---|---|---|

| FR4 | Strong, durable, cost-effective | Standard applications |

| CEM1 | Lightweight, good insulation | Basic single-sided PCBs |

| Polyimide | Flexible, thermal stability | Flexible PCBs |

| Aluminum | Excellent heat dissipation | LED PCBs, power electronics |

FR4 is the most widely used material for blank PCBs, and for good reason. It combines affordability with excellent electrical insulation properties and mechanical strength. The “F” in FR4 stands for “flame-resistant,” which is an important quality for ensuring safety in electrical applications.

But here’s the kicker—FR4 is not just about durability. It’s also about versatility. FR4 is suitable for a wide range of industries, from consumer electronics to industrial applications. Its ability to withstand heat and environmental stress makes it a reliable choice for many electronic devices.

FR4-based PCBs are available in both rigid and flexible forms, making them suitable for a broad array of devices, including smartphones, medical equipment, and automotive electronics.

| Property | FR4 Benefits |

|---|---|

| Durability | High mechanical strength and resistance to wear. |

| Electrical Insulation | Excellent electrical insulating properties. |

| Versatility | Can be used in a wide range of applications. |

The distinction between a blank PCB and a finished PCB is quite significant. A blank PCB is essentially the bare foundation on which a circuit will eventually be built, while a finished PCB is fully populated with components like resistors, capacitors, and chips. A blank PCB has only copper traces, pads, and vias but lacks the electronic components that make it functional.

Once components are added to a blank PCB, it becomes a finished PCB ready for assembly and use in a device. The transition from blank to finished is not just a physical change; it also involves functional and electrical modifications, which allow the board to perform specific tasks in a circuit.

What’s the real story? This transformation is what makes blank PCBs so important—without them, there would be no base for the complex components that power modern electronics.

| Blank PCB | Finished PCB |

|---|---|

| Contains only traces, pads, and vias | Fully populated with components |

| Used as a base for creating circuits | Ready for use in devices |

Blank PCBs serve as the foundation for nearly every electronic device today. Their applications are vast and varied, ranging from simple household electronics to complex industrial machinery. Some of the most common applications include:

Consumer Electronics: Blank PCBs are used in products like televisions, smartphones, and computers, where they form the base for various functional components.

Automotive: In cars, blank PCBs are used in systems like entertainment units, sensors, and control modules.

Industrial Electronics: Blank PCBs are integral to factory automation systems, robotics, and machinery control systems.

Ready for the good part? The growing demand for connected devices and smart technologies means that blank PCBs will continue to play a crucial role in shaping the future of electronics.

| Application Area | Examples |

|---|---|

| Consumer Electronics | Smartphones, televisions, computers |

| Automotive | Sensors, control units, infotainment systems |

| Industrial Electronics | Robotics, factory automation, machinery control |

Q1: What is a blank PCB board?

A blank PCB board is a bare circuit board that contains copper traces, pads, and vias but has no components attached. It is the foundation for creating functional circuit boards.

Q2: How are blank PCB boards manufactured?

Blank PCB boards are manufactured through a process that includes material preparation, copper coating, etching, drilling, and surface finishing to create the necessary connections and pads.

Q3: What materials are used in blank PCB boards?

Blank PCB boards are typically made from materials like FR4, CEM1, polyimide, and aluminum, each chosen for its specific properties such as durability, flexibility, or heat dissipation.

Q4: Why is FR4 a popular choice for blank PCBs?

FR4 is popular because it offers a great balance of affordability, durability, and electrical insulation properties. It is versatile enough for a wide range of applications.

Q5: How does a blank PCB differ from a finished PCB?

A blank PCB contains only the basic structure of traces, pads, and vias. A finished PCB, on the other hand, is populated with electronic components that make it functional.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote