Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

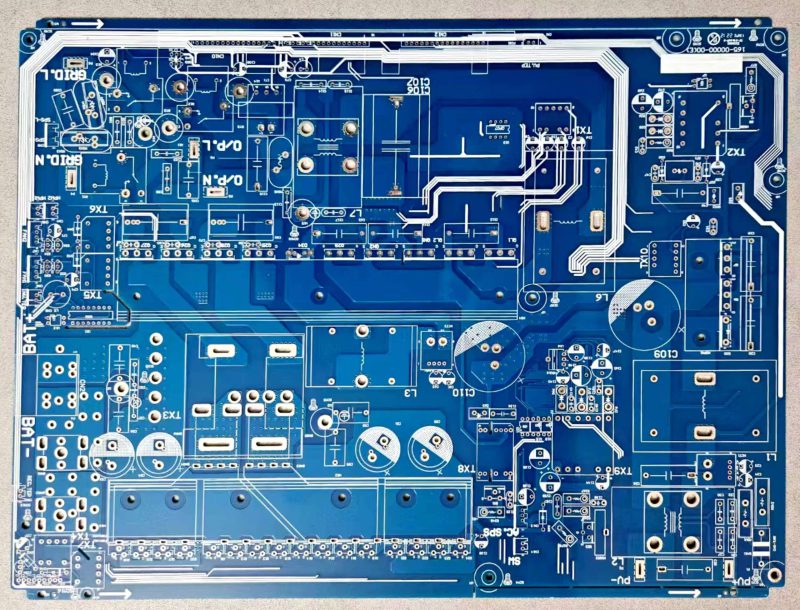

Let’s kick off with the basics—what’s a PCB board, and why does every modern electronic device depend on one? The answer is both simple and surprisingly nuanced. A PCB, or printed circuit board, is the silent workhorse behind your phone, laptop, car electronics, and every smart device you know. But here’s the kicker… without a properly specified PCB, even the best design in the whttps://www.pcbsupplier.com/pcb-manufacturing-process/orld will sputter and fail.

PCBs are essentially platforms that hold electronic components and connect them via copper traces etched into a laminated substrate. There’s a wide variety: single-sided, double-sided, multilayer, rigid, and flexible—each has its own application sweet spots. Single-sided PCBs are most common in low-cost gadgets and power supplies, while multilayer PCBs dominate in high-performance servers, IoT devices, and automotive control modules.

The significance of the PCB board lies in its role as the “central nervous system” of electronics. For B2B buyers, the real story is that your choice of PCB directly impacts product quality, manufacturing cost, and even your ability to scale production. In fact, over 70% of electronic failures can be traced back to PCB problems—often due to poor materials, design flaws, or manufacturing errors.

PCB boards offer key benefits: they reduce wiring complexity, shrink device size, enhance electrical performance, and improve overall reliability. Ready for the good part? By understanding your PCB options, you position your business to deliver better products, faster—while managing risks and costs. Let’s explore what makes these boards essential for any electronics application.

Buy PCB Board

| Type | Layers | Typical Application | Cost | Complexity |

|---|---|---|---|---|

| Single-sided | 1 | LED lighting, toys | Low | Simple |

| Double-sided | 2 | Power supplies, controls | Medium | Moderate |

| Multilayer | 4–32+ | Servers, medical, telecom | High | Advanced |

| Rigid | 1–32+ | Most consumer electronics | Medium | Moderate |

| Flexible | 1–8 | Wearables, automotive | High | High |

Let’s face it—building your own PCB from scratch is no small feat. What’s the real story? In the early days of electronics, DIY PCB fabrication was standard. But now, with tighter tolerances, faster timelines, and mass production needs, outsourcing is the name of the game.

Purchasing PCB boards instead of making them in-house saves you significant time and money. Why? Professional PCB suppliers use advanced manufacturing lines, tight quality control, and economies of scale—factors nearly impossible to replicate in a lab or small workshop. For example, a B2B client in the automotive sector moved from in-house PCB etching to buying finished boards, reducing costs by 40% and cutting lead time from weeks to days.

But here’s the kicker… off-the-shelf boards are typically more reliable, having undergone automated optical inspection, electrical testing, and even X-ray analysis. That means fewer defects and less rework during final assembly. Consider another example: a start-up in smart home devices sourced boards from a trusted vendor and slashed their R&D iteration time by half, freeing engineers to focus on innovation, not troubleshooting manufacturing issues.

And don’t forget regulatory compliance. Certified PCB makers adhere to IPC and UL standards, giving you documentation and audit trails essential for CE, FCC, or automotive approvals. Ready for the good part? By buying PCB boards, you free up resources for higher-value activities and gain the flexibility to ramp production up—or down—at a moment’s notice.

| Factor | Buy PCB Board | Make In-House |

|---|---|---|

| Setup Cost | Low | High |

| Quality | Consistent, certified | Variable |

| Lead Time | 2–10 days typical | Weeks or longer |

| Scalability | Easy | Limited |

| Compliance | Industry standards | Difficult to document |

Selecting the right PCB board is crucial for B2B buyers. Here’s where it gets interesting… not all PCBs are created equal, and a poor match can spell disaster for your product launch. Start by assessing your application: what are the electrical requirements, mechanical constraints, and environmental challenges?

For instance, a medical device might demand a multilayer rigid board with special insulation, while a wearable tracker needs a flexible, lightweight solution. An industrial control system may require high-temperature substrates like polyimide, whereas an LED module can use standard FR-4.

Let’s talk copper weight and trace width. Power electronics, for example, benefit from thicker copper and wider traces to handle high current, while signal processing PCBs require controlled impedance and tight spacing. Your choice of finish—HASL, ENIG, OSP—impacts both performance and assembly yield.

But here’s the kicker… don’t ignore supplier capability. Always verify that your vendor can meet your chosen specs, including minimum trace width, hole size, and surface finish. Consider case studies: a telecommunications OEM avoided costly delays by partnering early with a supplier who understood their need for impedance control across six PCB layers.

Finally, match your board specs to your assembly and testing environment. If you’re using automated pick-and-place, make sure the PCB flatness and panelization are suitable. Ready for the good part? With careful selection, you boost reliability, streamline assembly, and prevent expensive rework.

| Requirement | Typical Options | Key Considerations |

|---|---|---|

| Application | Medical, industrial, consumer | Compliance, durability |

| Board Type | Rigid, flexible, multilayer | Cost, performance |

| Substrate Material | FR-4, polyimide, ceramic | Temperature, impedance |

| Copper Weight | 1oz, 2oz, 3oz+ | Current capacity |

| Surface Finish | HASL, ENIG, OSP | Solderability, shelf life |

Navigating the world of PCB procurement can feel like a maze. But here’s the kicker… today’s buyers have more options than ever. You can purchase PCB boards through global online platforms, specialized manufacturers, or even local shops.

Online marketplaces—such as Alibaba, Digi-Key, and PCBWay—offer easy access to hundreds of suppliers. These platforms provide instant quotes, design file uploads, and tracking. However, not all suppliers are created equal, so check reviews, certifications, and response times before committing.

Prefer working with a specialized supplier? Companies like Shuoqiang Electronics or Jerico Multilayer PCB offer direct-to-customer sales, full DFM review, and tailored solutions for B2B buyers. Ready for the good part? Many suppliers now support online RFQ (request for quote) tools with 24-hour feedback and expedited prototyping.

Some companies choose local PCB shops for fast communication and reduced shipping times, especially for urgent or low-quantity needs. On the flip side, global suppliers can handle large volumes and complex requirements at competitive prices.

A real-world case: a Canadian industrial OEM switched to an Asian PCB factory for volume orders, cutting costs by 35%, while still using a local shop for fast-turn prototypes.

| Channel | Pros | Cons |

|---|---|---|

| Online Marketplaces | Variety, instant quotes, low prices | Mixed quality, communication |

| Specialized Suppliers | Custom service, quality assurance | Higher MOQ, longer lead times |

| Local Shops | Fast, personal support | Limited capability, higher cost |

| Global Manufacturers | Volume discounts, advanced options | Logistics, language barriers |

Here’s the million-dollar question: how do you evaluate a PCB supplier? Ready for the good part? It’s not just about price. Reliability, quality, and communication matter just as much.

Start by checking certifications—IPC-A-600, ISO 9001, UL, and RoHS are must-haves for most B2B applications. Ask for references or case studies relevant to your industry. If a supplier can’t produce documentation or explain their process, consider it a red flag.

Lead times are another crucial metric. Does your supplier deliver on time, every time? What’s their record for urgent orders or changes? You want a partner who’s as responsive on day 100 as on day one.

Pricing transparency is key. Make sure you get itemized quotes—no hidden setup fees or post-order surcharges. One automotive supplier famously lost a six-figure contract after a last-minute price hike. But here’s the real story… a supplier with slightly higher upfront costs but consistent quality and support can save you tenfold in rework and downtime.

Finally, assess after-sales support. Will they help troubleshoot issues post-delivery? Do they offer warranty or return policies? The right supplier becomes a true partner in your value chain.

| Criteria | Why It Matters | Questions to Ask |

|---|---|---|

| Certifications | Proves industry compliance | Do you have IPC/UL/ISO? |

| Lead Time | Impacts your delivery schedule | Can you handle urgent orders? |

| Pricing | Affects project budget | Are quotes itemized? |

| References | Validates supplier claims | Can I contact past clients? |

| After-sales Support | Resolves issues, builds trust | Is there a warranty? |

Cost isn’t just a number on a quote; it’s a complex equation. But here’s the kicker… understanding what drives PCB board price helps you control your budget and avoid sticker shock.

The major price factors are material type (FR-4, polyimide, ceramic), copper thickness, board size, and layer count. Complex features—like HDI microvias, blind/buried vias, or controlled impedance—add to the cost. Then, there’s the finish: ENIG costs more than HASL, and custom silkscreen or mask colors can bump up the bill.

Order volume is crucial. The price per unit drops sharply as quantities rise, thanks to setup cost amortization. Express production, tighter tolerances, or special certifications can add premiums, too.

A case study: A B2B telecom customer needed a 12-layer PCB with ENIG finish and 4oz copper. The board price doubled compared to their previous 2-layer, 1oz copper board, but their end-product performance justified the investment.

Don’t forget logistics. International shipping and customs duties can add up, especially with air freight. Ready for the good part? A transparent supplier will explain all price components upfront, so there are no surprises at payment time.

| Factor | Impact on Cost | Notes |

|---|---|---|

| Material | High for exotic types | FR-4 is standard, polyimide high |

| Copper Weight | Increases with thickness | Power or high-temp boards |

| Layers | More layers = higher cost | 2–32+ layers possible |

| Finish | ENIG > HASL > OSP | Affects assembly and life |

| Volume | Lower price at higher volume | Setup cost per order |

If you’re buying PCB boards, requesting a quote is step one. What’s the real story? Accurate, clear communication at this stage makes all the difference. Suppliers need your Gerber files, BOM (bill of materials), required specs, quantity, and preferred lead time.

Use the supplier’s online quote form or email. Most top-tier suppliers reply within 24 hours, especially for standard designs. If your board has unusual requirements, a phone call or video meeting may help clarify details and speed up the quoting process.

Always double-check your files before submission. Incomplete or error-filled data is the top reason for delays and misquotes. Ready for the good part? Many vendors offer free DFM (Design for Manufacturability) checks before formal quoting—catching issues that could drive up costs or cause production failures.

A real-life example: a startup provided only PDF schematics and faced multiple rounds of clarifications and delays. After switching to full Gerber and BOM submissions, their quote turnaround dropped from five days to one.

| Item | Why It’s Needed | Common Formats |

|---|---|---|

| Gerber Files | Defines copper layout | .zip, .rar |

| BOM | Specifies component placement | Excel, CSV |

| Quantity | Determines pricing/volume | Numeric |

| Lead Time | Schedules production | Days, weeks |

| Special Specs | Custom features/finishes | Written description |

Quality is everything in the world of B2B electronics. But here’s the kicker… a single defect can ripple through your supply chain, causing delays, recalls, or even brand damage.

Industry standards like IPC-A-600 (acceptability), IPC-6012 (performance), and UL (flammability) provide a common language for buyers and suppliers. Many markets also require RoHS or REACH compliance to ensure materials are safe for global distribution.

Testing is rigorous. Top suppliers run AOI, flying probe, X-ray, and electrical continuity checks on every panel. Some even offer sample boards for first-article inspection, so you can verify quality before full production.

Ready for the good part? Experienced suppliers provide COC (certificate of conformance) and batch traceability, so any issue can be traced—and fixed—fast. In one example, a medical device company identified a solder mask defect during incoming inspection and quickly got replacement panels thanks to traceability data.

| Standard | Focus Area | Certification Body |

|---|---|---|

| IPC-A-600 | Acceptability criteria | IPC |

| IPC-6012 | Qualification/performance | IPC |

| UL | Flammability/safety | Underwriters Labs |

| RoHS/REACH | Hazardous substance control | EU, international |

| ISO 9001 | Quality management systems | ISO |

Let’s break it down—how do you actually buy PCB boards, from quote to delivery? Ready for the good part? A well-defined process avoids errors and ensures you get the right product, on time.

First, submit your files and requirements for a quote. After confirming the price and lead time, place your order (often with a purchase order or online checkout). The supplier will review your files, possibly offering DFM feedback or revisions.

Next, the manufacturing process begins—patterning, etching, drilling, plating, and finishing. Throughout, you’ll receive status updates, and some suppliers offer real-time tracking. When boards are finished, you arrange payment and shipping.

Upon arrival, inspect your PCBs for defects or discrepancies. Any issues should be reported immediately for resolution. Repeat or production orders become easier after a successful first run.

A case in point: a robotics OEM streamlined purchasing by creating a standard PCB buying checklist and using suppliers with online portals, cutting admin work by 30%.

| Step | What Happens | Buyer Action Required |

|---|---|---|

| Quote Request | Files sent, quote received | Provide all data |

| Order Placement | Confirm price/specs, order sent | Issue PO/checkout |

| File Review/DFM | Supplier checks for issues | Approve or revise |

| Manufacturing | PCBs produced and inspected | Track progress |

| Delivery | Boards shipped to buyer | Receive and inspect |

| After-sales Support | Resolve issues, repeat orders | Communicate feedback |

Custom PCB boards are the backbone of product differentiation. But here’s the kicker… standard options rarely meet the needs of today’s innovative designs.

Custom boards let you define every parameter: layer count, materials, thickness, copper weight, hole size, solder mask color, and even surface finish. They also allow for special shapes, cutouts, and non-standard dimensions. The only limit is your imagination—and your supplier’s capabilities.

A recent case: an industrial automation firm needed a 10-layer rigid-flex board with gold fingers and ENIG finish. By collaborating with a specialized manufacturer, they went from concept to working prototype in under three weeks.

However, the process is more demanding. Precise communication is crucial; all details must be agreed upon before production. Most suppliers will run detailed DFM reviews and require signed approval on final specs.

Ready for the good part? Custom boards may cost more up front, but they often result in savings through higher performance, easier assembly, and lower field failure rates.

| Feature | Custom PCB Board | Standard PCB Board |

|---|---|---|

| Parameters | Fully defined | Limited options |

| Cost | Higher | Lower |

| Lead Time | Longer (design, review) | Shorter |

| Application Fit | Exact | Generalized |

| DFM Review | Essential | Sometimes omitted |

Prototyping is where your PCB ideas come to life. What’s the real story? Rapid prototyping has revolutionized product development—gone are the days when a single revision took months.

Now, you can order as few as five prototype PCBs and have them delivered in a week or less. This accelerates R&D and lets you test, revise, and optimize before investing in mass production.

For example, a consumer electronics startup iterated through four prototype versions before locking in a design, discovering critical layout and assembly improvements at each step. Another B2B client saved thousands by spotting a routing error during prototype testing, long before a high-volume order.

Don’t forget, prototype runs may differ slightly from final production in material, finish, or testing scope—always clarify expectations with your supplier.

Ready for the good part? Some advanced manufacturers offer prototype-to-production continuity, so you work with the same team from day one to high-volume rollout.

| Factor | Prototype PCB | Production PCB |

|---|---|---|

| Order Size | 5–50 boards typical | 100–100,000+ |

| Lead Time | 2–7 days | 7–21 days |

| Cost per Unit | Higher | Lower |

| Material/Finish | May differ | Finalized |

| Testing | Limited or standard | Full (including batch) |

Shipping and logistics can make or break

your PCB supply chain. Here’s where it gets interesting… even a perfect board is worthless if it arrives late or damaged.

For international orders, choose shipping modes (air, sea, express courier) based on urgency, cost, and customs complexity. Air express (DHL, FedEx) is fastest—often 2–5 days globally—but costs more. Sea freight is cheaper for large volumes but takes weeks.

Be aware of customs duties and import regulations in your country. Some suppliers offer DDP (Delivered Duty Paid), covering all shipping and customs costs up front. This simplifies purchasing but can add 5–10% to the landed cost.

Real case: an Indian electronics OEM avoided project delays by switching from sea to air freight for urgent orders, even though the cost was higher.

Packaging is crucial—static shielding, moisture barriers, and strong outer cartons prevent transit damage. Ready for the good part? Top suppliers provide real-time tracking and post-shipment support, so you always know where your boards are.

| Method | Speed | Cost | Ideal For |

|---|---|---|---|

| Air Express | 2–5 days | High | Prototypes, urgent orders |

| Air Freight | 5–10 days | Medium | Medium volume, regular |

| Sea Freight | 2–6 weeks | Low | Large volume, low urgency |

| Courier | 1–7 days | Variable | Local or small shipments |

Here’s the real story… after-sales support can be the deciding factor in a long-term supplier relationship. The best PCB suppliers offer clear warranty terms, speedy problem resolution, and a commitment to your project’s ongoing success.

Check the supplier’s defect policy—will they replace boards or issue refunds for any found nonconforming in incoming inspection? Ask how long the warranty lasts (often 12–24 months for B2B). Some suppliers even provide remote troubleshooting or on-site support for complex issues.

A high-profile example: a robotics firm detected an intermittent open circuit on 2% of received boards. The supplier sent replacement panels in 48 hours, avoiding assembly downtime and cementing a multi-year relationship.

Don’t overlook the value of direct engineer access. Suppliers who provide a single point of contact or quick escalation channels save you time and stress.

Ready for the good part? Strong after-sales support turns a vendor into a strategic partner—one who shares in your success and helps you innovate faster.

| Feature | Best-in-Class | Standard | Poor |

|---|---|---|---|

| Warranty Length | 12–24 months | 6–12 months | None |

| Replacement Policy | 100% for defects | Partial/negotiable | None or slow |

| Tech Support | Direct engineer access | Ticket/email only | Unresponsive |

| Escalation Path | Fast, documented | Informal | None |

Nobody likes surprises—especially in procurement. But here’s the kicker… most PCB buying headaches can be traced to just a few avoidable mistakes.

Common pitfalls include incomplete design files, unclear specifications, and failure to confirm supplier credentials. Others forget to budget for import duties or underestimate lead times, missing key project deadlines.

Another danger: ignoring prototype validation and jumping straight to mass production, only to find costly design flaws. And beware of “too good to be true” prices—these often mask poor quality or hidden fees.

Case in point: a B2B buyer rushed an order with an unknown supplier for 5,000 boards at a rock-bottom price. The boards failed during assembly, leading to lost contracts and expensive recalls.

Ready for the good part? With careful preparation and reliable partners, you’ll avoid these pitfalls and keep your supply chain strong.

| Mistake | Consequence | How to Avoid |

|---|---|---|

| Incomplete Files | Delays, errors | Double-check submissions |

| Ignoring Certifications | Low quality, compliance issues | Verify before ordering |

| Skipping Prototypes | Production failures | Always prototype first |

| Unclear Specs | Miscommunication | Detailed RFQ and documentation |

| Chasing Low Prices | Quality risk, hidden fees | Balance cost and reliability |

The PCB world is evolving fast. What’s the real story? Digitalization, automation, and sustainability are redefining how businesses buy PCB boards.

Online quoting and AI-powered DFM reviews are speeding up the process—some suppliers now provide instant pricing based on uploaded Gerber files. Smart manufacturing, including Industry 4.0, is driving down lead times and boosting traceability.

There’s also a growing push for green supply chains—lead-free, RoHS-compliant, and recyclable materials are the new normal. Some advanced suppliers offer carbon footprint tracking and offset programs.

A key trend is integration: platforms that connect buyers, designers, and manufacturers for seamless collaboration. Ready for the good part? These advances are making PCB procurement more transparent, efficient, and eco-friendly.

B2B buyers who keep up with these trends will secure faster deliveries, better pricing, and lower risk in a fiercely competitive market.

| Trend | Impact | Opportunity |

|---|---|---|

| Online Quoting | Faster pricing, less admin | Reduce time-to-market |

| AI/DFM Automation | Fewer errors, better quality | More reliable production |

| Green Manufacturing | Compliance, brand image | Attract eco-conscious clients |

| Smart Logistics | Real-time tracking | Better risk management |

| Collaborative Platforms | Streamlined sourcing | Integrated workflow |

Buying PCB boards is both a science and an art. By understanding the basics, choosing the right partners, and keeping an eye on costs, quality, and logistics, you set your business up for lasting success. From initial quote to after-sales support, every step matters—so never settle for less than transparency and reliability. What’s the real story? In today’s fast-paced electronics world, your supplier can be your strongest asset or your biggest risk. Choose wisely, embrace innovation, and your projects will run smoother, faster, and more profitably than ever.

Q1: What is a PCB board?

A PCB (Printed Circuit Board) is a platform that supports and connects electronic components using conductive copper traces and a non-conductive substrate.

Q2: How does the online PCB board purchasing process work?

You select a supplier, upload design files and requirements, receive a quote, place your order, and the manufacturer produces and ships your PCB boards.

Q3: What are the most important factors when choosing a PCB supplier?

Look for certifications, track record, lead times, pricing transparency, and strong after-sales support to ensure reliable quality and service.

Q4: How can I ensure my PCB boards meet quality standards?

Work with certified suppliers, request COC and inspection reports, and perform incoming quality checks upon delivery.

Q5: What are common mistakes to avoid when buying PCB boards?

Don’t submit incomplete files, skip prototyping, ignore supplier credentials, or be lured by unreasonably low prices—these all risk quality and delivery.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote