Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

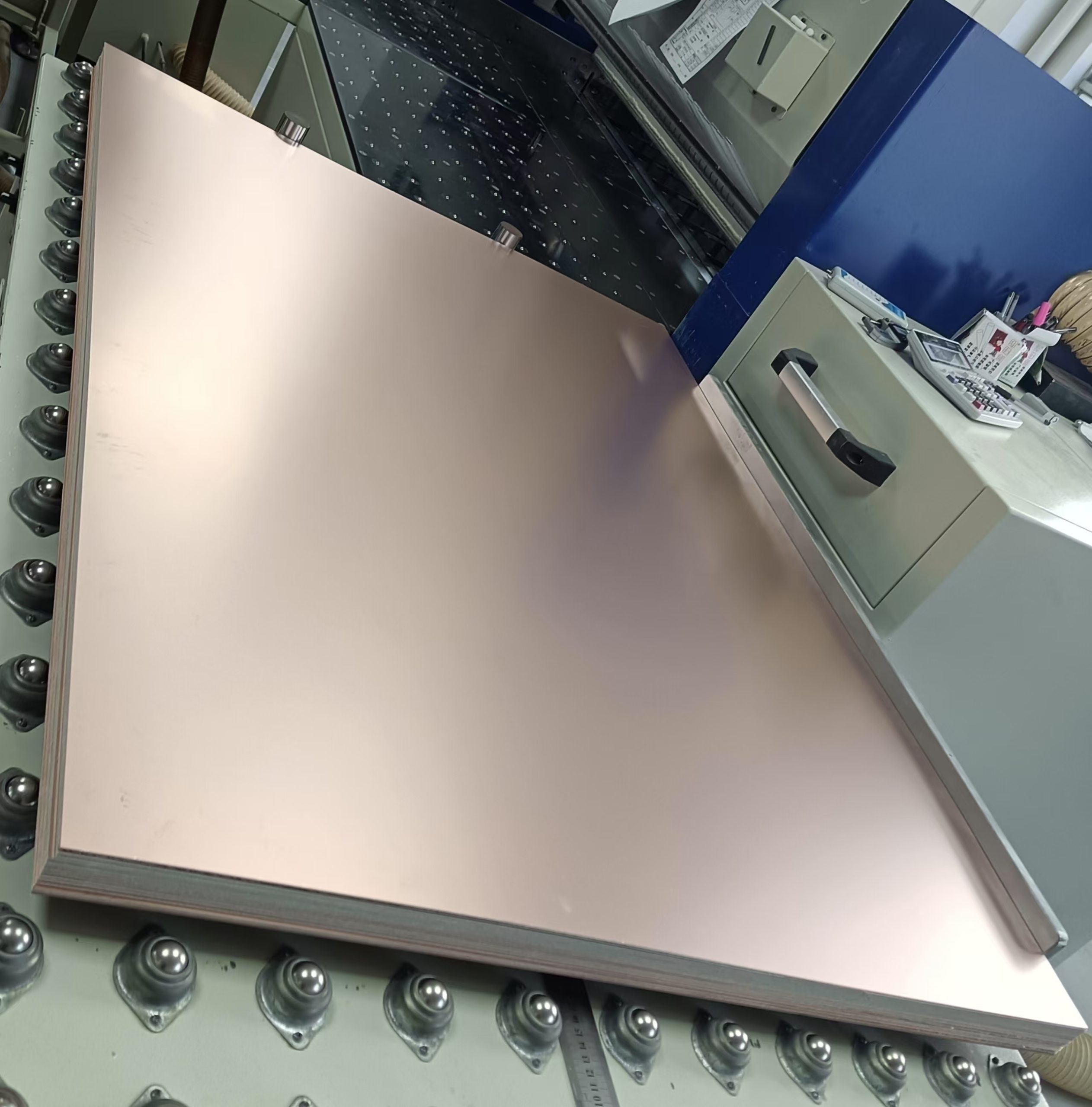

Copper Clad Laminate (CCL) is a core base material used in the manufacturing of printed circuit boards (PCBs). It is made by impregnating reinforcing materials such as fiberglass cloth with resin and then laminating both sides with copper foil under heat and pressure. CCL provides both mechanical support and the foundation for electrical signal transmission in electronic devices.

What is Copper Clad Laminate (CCL)?

As electronic manufacturing continues to evolve, CCL has emerged as a distinct and vital segment within the supply chain.

According to industry research, the global copper clad laminate market reached USD 16.88 billion in 2023, and is expected to grow to USD 23.01 billion by 2030, with a CAGR of 4.6%. This strong growth demonstrates CCL’s critical role in modern electronics across consumer, industrial, and automotive applications.

With copper clad laminate as the foundation, PCB manufacturers can easily produce circuit boards in various thicknesses and circuit patterns, according to the functional and design requirements of the product. CCL enables flexibility in manufacturing simple single-layer PCBs to complex multilayer high-frequency boards.

CCLs are categorized based on several factors:

Rigid CCL: Used in standard PCB fabrication with fixed structure and shape.

Flexible CCL (FCCL): Designed for foldable or bendable applications like wearables.

Organic Resin CCL: Made from epoxy or phenolic resin; widely used.

Metal-based CCL: Aluminum or copper base; excellent heat dissipation.

Ceramic-based CCL: High thermal and frequency stability; used in RF and power electronics.

Thick Boards: 0.8–3.2 mm; for mechanical strength.

Thin Boards: Less than 0.8 mm; ideal for compact electronics.

Glass Fiber Cloth Base (FR4): High strength and good dielectric performance.

Paper-based CCL: Cost-effective but lower durability.

Composite Base (CME-1, CME-2): Combines different materials for balanced performance.

Flame Retardant CCL: Meets UL94-V0 or equivalent fire resistance standards.

Non-Flame Retardant CCL: For general-purpose electronics without fire regulations.

Quality copper clad laminates must conform to a series of international standards and performance indicators, including:

IPC-4101C: Specification for base materials for rigid and multilayer PCBs.

IPC-IM-650: Standard test methods for electrical, thermal, and mechanical properties of CCL.

ASTM D1867: Covers peel strength at high temperatures, flexural strength (lengthwise/crosswise), blister resistance, and warpage.

These standards ensure that the CCL meets stringent requirements in:

Peel strength

Dimensional stability

Thermal resistance

Dielectric loss

Surface quality and chemical resistance

CCLs are used across a wide range of industries and applications, including:

Consumer Electronics: Smartphones, TVs, radios, computers

Communication Systems: Routers, 5G equipment, telecom modules

Medical Devices: Wearable health monitors, diagnostic tools

Automotive Electronics: Sensors, controllers, EV battery systems

Industrial Control: PLCs, industrial computing, automation boards

Military & Aerospace: High-reliability multilayer PCB systems

Copper Clad Laminate (CCL) is more than just a raw material—it’s a cornerstone of modern electronic manufacturing. From consumer devices to high-reliability industrial systems, CCL supports innovation through its versatility, performance, and scalability.

With global standards and rising demand, CCL continues to evolve as a standalone industry, powering the next generation of electronic design.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote