Why DI Exposure Machines Are the Top Choice for Modern PCB Production?

Challenges of Traditional PCB Supplier: Low Precision, High Cost, Slow Efficiency

In the fast-evolving electronics industry, every PCB determines the performance limits of a device. However, traditional photolithography processes are struggling to keep up with modern PCB manufacturing demands:

- Limited Precision – Traditional film-based exposure relies on photomasks, which often cause alignment errors, affecting circuit accuracy.

- Long Production Cycles – Photomask production and alignment are time-consuming, leading to delays in delivery.

- High Costs – Photomasks are expensive, prone to damage, and add to long-term expenses.

In recent years, DI (Direct Imaging) exposure machines have experienced explosive growth in the PCB industry. Compared to traditional exposure machines, DI exposure offers massive advantages in precision, production efficiency, and cost reduction.

Now, when customers visit a PCB factory for evaluation, not having a DI exposure machine is often an instant deal-breaker. Customers prefer manufacturers equipped with DI technology because they understand that traditional exposure methods cannot meet the quality requirements of modern PCB production.

DI Exposure Machines

How DI Exposure Machines Work?

Laser Direct Imaging: From Physical Photomasks to Digital Imaging

Traditional exposure relies on photomasks, where UV light passes through the mask to expose the PCB. DI technology, on the other hand, uses high-power UV lasers to directly image circuits onto the photoresist-coated PCB, achieving ultra-precise patterning.

- Fully digital control, achieving resolutions as fine as 15μm or lower.

- Automated calibration, eliminating manual alignment errors and improving yield.

- Real-time data adjustments, adapting to complex and variable circuit designs.

DI Exposure Machine Prices: From High Costs to Affordability

- Four years ago, a single-sided DI exposure machine cost over $300,000, making it unaffordable for many PCB factories.

- Today, even a dual-sided DI exposure machine costs less than $150,000, significantly lowering the barrier to entry.

- Lower costs and more mature technology have made DI exposure an essential investment for PCB manufacturers.

DI Exposure vs. Traditional Exposure: Which One Wins?

Optimized Efficiency and Cost Savings

| Feature |

DI Exposure Machine |

Traditional Photomask Exposure |

| Production Cost |

No photomasks needed, long-term cost savings |

High photomask costs, frequent replacements |

| Production Efficiency |

Direct imaging, no need to switch photomasks |

Requires additional photomask preparation |

| Precision |

±15μm, ideal for HDI PCBs |

±50μm, prone to errors |

| Defect Rate |

No photomask contact, reducing contamination |

Photomask contact may cause defects |

| Maintenance Cost |

Lower, reduces AOI and QC workload |

Higher, requiring more AOI and QC inspections |

| ROI |

Machine cost can be recovered within 1.5 years |

Ongoing photomask costs add up over time |

How DI Exposure Reduces Defects and Increases Yield?

How DI Exposure Machines Improve PCB Quality?

Intelligent Compensation for Shrinkage and Expansion, Preventing Exposure Misalignment

- DI exposure machines adjust the imaging scale for each individual PCB to compensate for material shrinkage and expansion.

- This reduces exposure misalignment issues, preventing common defects associated with traditional photomasks.

- Eliminates photomask rejection issues, enhancing production stability.

The Ultimate Solution for BGA Exposure Alignment

BGA (Ball Grid Array) PCBs require ultra-precise alignment, and traditional exposure methods often struggle with misalignment, leading to poor solder joint connections.

- DI exposure machines accurately control imaging positions, reducing misalignment and significantly improving BGA yields.

- Manufacturers achieve more consistent product quality, strengthening customer confidence and increasing order conversions.

Bridging the Quality Gap Between Small and Large PCB Manufacturers

- Previously, only large-scale PCB manufacturers could afford DI exposure machines, allowing them to maintain superior quality control.

- Now, with DI equipment becoming more affordable, smaller PCB manufacturers can achieve high-end production standards, leveling the playing field in the industry.

Industries That Benefit the Most from DI Technology

Smartphones and Consumer Electronics

- In the 5G era, PCB traces are denser, requiring higher precision.

- High-end smartphone motherboards use DI exposure for HDI PCB processing, ensuring signal integrity.

Electric Vehicles and Autonomous Driving

- Automotive electronics require high-reliability PCBs with long lifespans—DI enables precise manufacturing.

- Autonomous driving sensors and ADAS systems rely on HDI PCBs, and DI exposure ensures their production quality.

Medical Electronics and Industrial Control

- Miniaturized medical devices like pacemakers and diagnostic equipment require micro-precision PCBs, which DI exposure can achieve.

- Industrial automation systems demand high-durability PCBs, and DI exposure guarantees top-quality production.

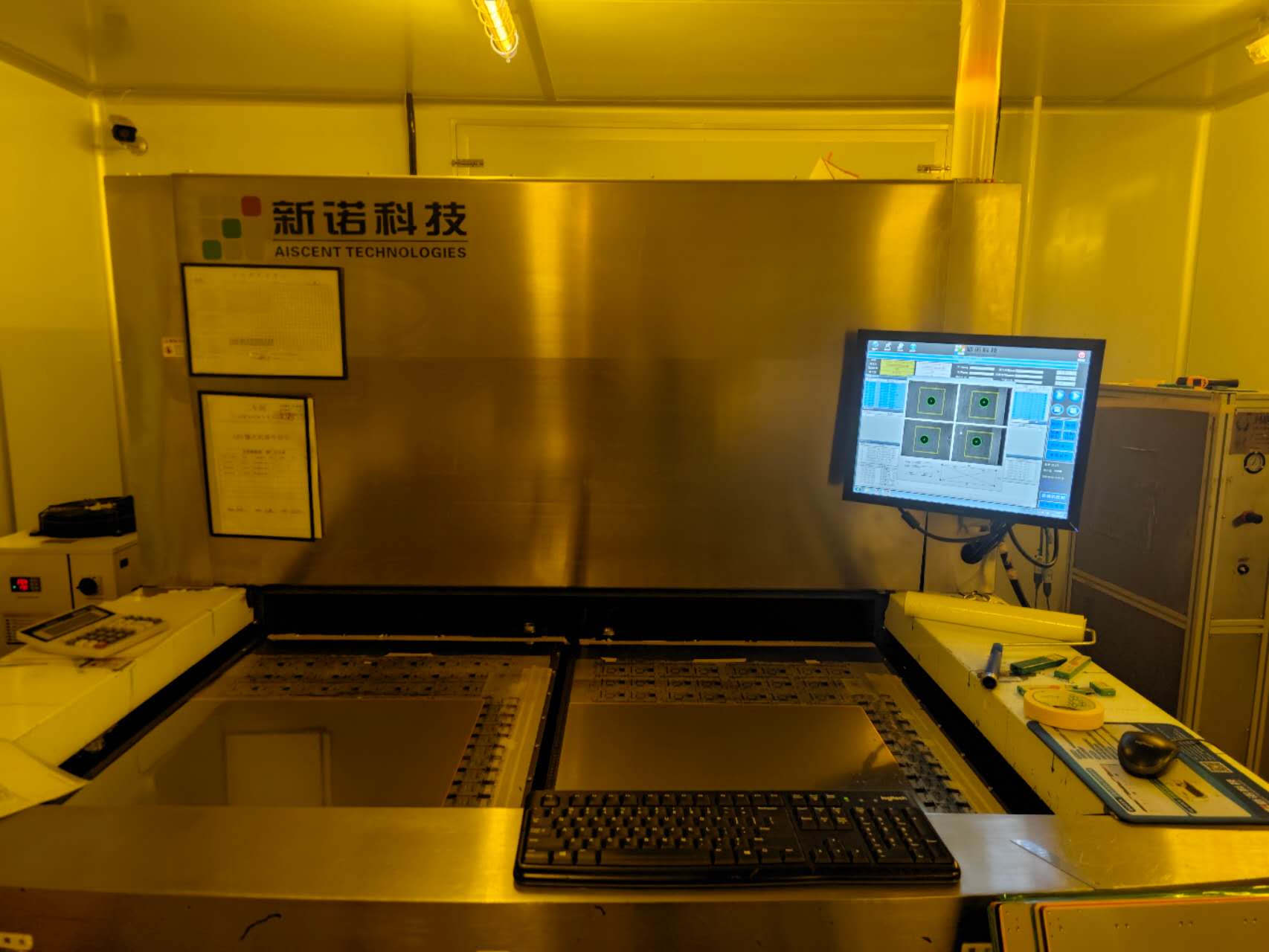

Jerico Multilayer PCB: Ensuring High-Quality Standards with DI-Exposure Machines

At Jerico Multilayer PCB, we have fully integrated DI circuit exposure and DI solder mask exposure machines into our production process. This advanced equipment not only enhances precision but also significantly improves overall product quality.

- DI circuit exposure ensures ultra-precise trace definition, reducing manufacturing defects.

- DI solder mask exposure improves layer alignment, minimizing soldering issues and enhancing board reliability.

- Our state-of-the-art DI technology reassures customers of consistent, high-quality PCB production, setting us apart from competitors.

With these capabilities, Jerico Multilayer PCB can confidently meet the highest industry standards, ensuring superior performance for all our customers.

Conclusion: Why DI Exposure Machines Are the Future of PCB Manufacturing?

DI-exposure machines are revolutionizing PCB manufacturing with unmatched precision, efficiency, and cost-effectiveness. With a return on investment of just 1.5 years, DI technology drastically reduces defects, enhances quality, and lowers operational costs—making it a must-have for any modern PCB factory.

For PCB manufacturers looking to improve production capabilities, reduce costs, and meet high-end market demands, investing in DI exposure technology is no longer optional—it’s essential for staying competitive.

At Jerico Multilayer PCB, our investment in cutting-edge DI-exposure machines guarantees top-tier quality, reliability, and precision. Ready to take your PCB manufacturing to the next level? Contact us today!

Well-known PCB supplier

Well-known PCB supplier