Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

A metal core PCB (MCPCB) is a type of printed circuit board with a metal-based substrate, usually aluminum or copper, that enhances its thermal conductivity. Unlike standard FR4 boards, which use fiberglass-based substrates, metal core PCBs are designed to handle high heat and power dissipation. They are essential for applications where thermal management is critical, such as in high-power devices like LED lighting, power supplies, and automotive systems. This article will explore the structure, advantages, applications, and design tips for metal core PCBs.

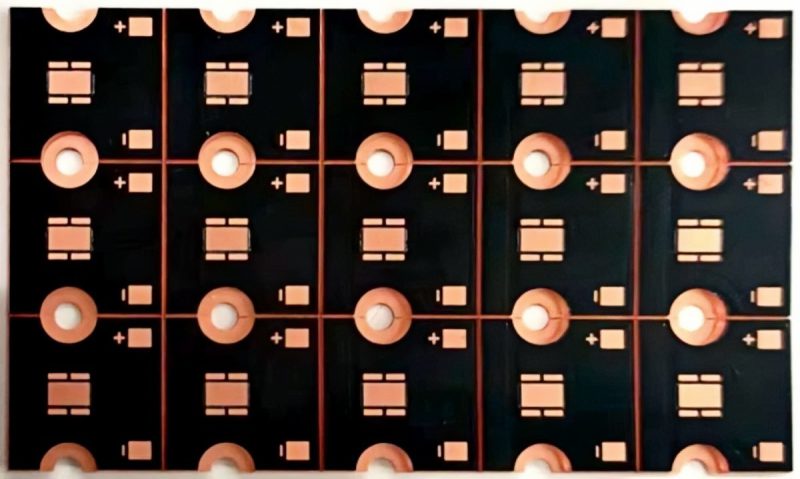

Metal Core PCB

Metal core PCBs are engineered to solve the issue of heat dissipation in high-power electronic devices. These PCBs use a metal-based substrate instead of the standard fiberglass resin. This unique feature allows the board to absorb and dissipate heat more efficiently, making them ideal for applications that generate significant amounts of heat, such as in power electronics, LEDs, and automotive systems.

What’s the real story? Without proper heat management, electronic devices can overheat, causing failure or reduced lifespan. Metal core PCBs provide an effective solution to this problem, offering better performance, durability, and reliability compared to traditional PCBs.

| Feature | Metal Core PCB | Traditional PCB |

|---|---|---|

| Material | Aluminum, Copper, or other metal substrates | FR4 (fiberglass-based) |

| Thermal Conductivity | High, effective heat dissipation | Lower, prone to overheating |

| Common Applications | High-power devices, LED lighting, automotive | Consumer electronics, basic circuits |

The structure of a metal core PCB is composed of several layers, each serving a specific function. At the heart of a metal core PCB is the metal substrate, typically made from aluminum, copper, or another metal material with high thermal conductivity. This metal layer is responsible for absorbing and dissipating heat from the components mounted on the board.

The metal substrate used in metal core PCBs significantly enhances thermal performance. Aluminum is the most commonly used material due to its balance of cost and thermal properties, but copper is sometimes used in applications requiring higher thermal conductivity.

The primary benefit of using metal core PCBs is their ability to manage heat. Heat generated by electronic components is transferred from the components to the metal substrate, where it is then dissipated across the surface. This prevents overheating, ensuring that components perform optimally for longer periods.

Metal core PCBs typically have a layer of insulating material between the metal base and the copper traces, ensuring that the electrical properties are maintained while still allowing for superior thermal dissipation.

This is where it gets interesting… The layering structure of a metal core PCB is designed not just for electrical functionality, but to maximize thermal performance, making them indispensable in high-performance applications.

| Layer | Description |

|---|---|

| Metal Substrate | Provides thermal dissipation |

| Insulating Layer | Ensures electrical insulation while transferring heat |

| Copper Traces | Connects components and routes electrical signals |

The operation of a metal core PCB centers around its ability to handle high levels of heat. Electronic components generate heat during operation, and metal core PCBs efficiently absorb and transfer this heat away from the components, preventing the board from overheating.

The metal substrate in metal core PCBs acts as a heat sink. As the components on the PCB generate heat, the metal base absorbs this heat and disperses it into the surrounding environment. This ensures that the components stay within safe operating temperatures, reducing the risk of failure due to excessive heat.

Thermal resistance is the ability of the PCB to resist heat flow. Metal core PCBs have much lower thermal resistance compared to traditional PCBs, making them more efficient in dissipating heat. This is particularly crucial in power-hungry applications like LED drivers, where heat management is a primary concern.

What’s the real story? In high-power applications, such as those in industrial machinery or LED lighting, the ability to manage heat effectively can significantly extend the lifespan of the device and improve overall performance.

| Property | Metal Core PCB | Traditional PCB |

|---|---|---|

| Thermal Resistance | Low, effective heat dissipation | Higher, prone to heat build-up |

| Substrate Material | Aluminum or copper | FR4 or fiberglass |

| Heat Dissipation | Excellent, ideal for high-power electronics | Limited, requires additional cooling |

Metal core PCBs offer several advantages over traditional PCBs, particularly in applications that require efficient thermal management. These advantages include better heat dissipation, improved reliability, and enhanced durability in high-power environments.

The key advantage of metal core PCBs is their superior ability to manage heat. Unlike traditional PCBs that rely on air or additional cooling methods, metal core PCBs can dissipate heat directly from the components, improving overall performance and reliability.

Metal core PCBs are more durable than traditional PCBs because they are less likely to warp or fail under high thermal stress. This makes them ideal for use in harsh environments, such as automotive or industrial applications, where components are subjected to extreme conditions.

By providing better heat management, metal core PCBs help to reduce the risk of component failure. This makes them more reliable in high-power applications, where the risk of overheating is high.

Ready for the good part? Metal core PCBs not only enhance the performance of electronic devices but also contribute to their longevity by preventing heat-induced failures.

| Advantage | Description |

|---|---|

| Thermal Management | Efficient heat dissipation reduces overheating |

| Durability | Better performance under thermal stress |

| Reliability | Fewer failures due to effective thermal control |

Metal core PCBs are used in a wide range of applications, particularly those requiring efficient heat management. Some of the most common applications include LED lighting, power electronics, automotive systems, and telecommunications.

One of the most common applications for metal core PCBs is LED lighting. LEDs generate a significant amount of heat, and metal core PCBs help dissipate this heat, improving the lifespan and performance of the LED modules.

Metal core PCBs are also used in power electronics, such as power supplies, inverters, and motor controllers. These applications require PCBs that can handle high currents and dissipate the heat generated during operation.

In automotive applications, metal core PCBs are used in control systems, sensors, and lighting systems, where heat dissipation is critical to ensuring the longevity and reliability of the components.

But here’s the kicker… The versatility of metal core PCBs in handling heat makes them indispensable in high-power applications across various industries.

| Application | Description |

|---|---|

| LED Lighting | Used for efficient heat dissipation in LED modules |

| Power Electronics | Ideal for power supplies, inverters, and motor controllers |

| Automotive Systems | Utilized in sensors, control systems, and automotive lighting |

The material used for the substrate in a metal-core PCB directly influences its performance, especially its ability to dissipate heat. The two most commonly used metals are aluminum and copper.

Aluminum is the most commonly used material for metal core PCBs due to its cost-effectiveness and good thermal properties. It is widely used in general-purpose applications, including LED lighting, power supplies, and automotive systems.

Copper substrates offer superior thermal conductivity compared to aluminum, making them ideal for high-performance applications where heat dissipation is critical. Copper-based PCBs are typically used in advanced applications, such as high-power power supplies and telecommunications equipment.

When choosing between aluminum and copper, the decision typically depends on the specific thermal and electrical needs of the application. While aluminum is sufficient for most applications, copper is necessary for designs requiring higher thermal conductivity and reliability.

This is where it gets interesting… Choosing the right substrate material for your metal core PCB is crucial for maximizing both performance and cost-effectiveness.

| Material | Thermal Conductivity | Cost | Ideal Use Case |

|---|---|---|---|

| Aluminum | Moderate | Lower | General-purpose applications like LED lighting |

| Copper | High | Higher | High-performance applications requiring superior heat dissipation |

Designing a metal-core PCB requires careful consideration of the thermal properties, electrical requirements, and mechanical constraints. Here are some essential design tips to ensure the board performs optimally.

Before beginning the physical design, thermal simulations are often performed to predict how heat will dissipate across the PCB. This helps designers ensure that the components are properly positioned to avoid overheating.

Proper placement of components is critical for efficient heat dissipation. Components that generate more heat should be placed away from sensitive components, and heat sinks should be incorporated into the design when necessary.

PCB routing for metal core PCBs requires special attention to trace width, spacing, and positioning to ensure efficient power distribution and heat dissipation. Using wider traces for high-current components and optimizing via usage is essential for maintaining performance.

What’s the real story? Proper design of a metal core PCB ensures that the heat generated by the components is effectively dissipated, preventing failure and ensuring reliable operation over time.

| Consideration | Impact | Solution |

|---|---|---|

| Thermal Simulation | Helps predict heat distribution and potential problems | Use thermal simulation software to optimize design |

| Component Placement | Impacts heat dissipation and device performance | Place high-heat components away from sensitive areas |

| Routing | Affects signal integrity and thermal efficiency | Use proper trace width and minimize via usage |

In conclusion, metal-core PCBs are essential components in modern electronics, offering superior heat dissipation, reliability, and durability. From LED lighting to power electronics, their applications are vast and growing. By selecting the right materials, optimizing design for thermal management, and considering the specific needs of the application, metal core PCBs can significantly improve the performance and lifespan of electronic devices.

And now you know the full story on metal-core PCBs! These versatile components are a cornerstone in many high-performance devices, offering effective solutions to heat management and power distribution challenges.

Q1: What is a metal-core PCB?

A1: A metal-core PCB is a type of printed circuit board with a metal-based substrate, typically aluminum or copper, designed to efficiently dissipate heat in high-power applications.

Q2: How does a metal-core PCB work?

A2: Metal-core PCBs work by absorbing heat from components and dispersing it through the metal substrate, preventing overheating and ensuring optimal performance.

Q3: What are the advantages of using metal-core PCBs?

A3: Metal-core PCBs offer better heat dissipation, improved durability, and enhanced reliability, making them ideal for power-hungry applications like LEDs and automotive systems.

Q4: What materials are used in metal-core PCBs?

A4: The most common materials for metal-core PCBs are aluminum and copper, each chosen based on their thermal properties and the specific requirements of the application.

Q5: How do I design a metal-core PCB?

A5: Designing a metal core PCB involves considering thermal management, proper component placement, and efficient routing techniques to ensure heat dissipation and reliability.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote