Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

Choosing the right PCB material is a critical step in ensuring the performance, durability, and cost-effectiveness of your product. The right material not only enhances the electrical and thermal performance of the circuit board but also directly impacts its mechanical strength and overall reliability. In this guide, we will explore the most commonly used PCB materials, the factors to consider when selecting them, and how to choose the ideal material for your project.

Types of PCB Materials

Selecting the right PCB material involves understanding several key factors. First and foremost, the material’s electrical properties must meet the requirements of the application. For example, high-frequency designs will require materials with low dielectric constants to prevent signal loss. Additionally, thermal performance is another essential consideration. The material must be able to dissipate heat effectively, particularly for high-power or densely packed designs. Mechanical properties such as strength, flexibility, and resistance to stress are also crucial, as they determine the material’s longevity and performance under various conditions.

But here’s the kicker—each PCB material has its own set of strengths and limitations. Understanding these characteristics allows manufacturers to choose materials that strike the right balance between cost, performance, and durability.

| Factor | Consideration |

|---|---|

| Electrical Properties | Low signal loss, appropriate dielectric constant |

| Thermal Performance | Effective heat dissipation, temperature tolerance |

| Mechanical Properties | Strength, flexibility, resistance to environmental stress |

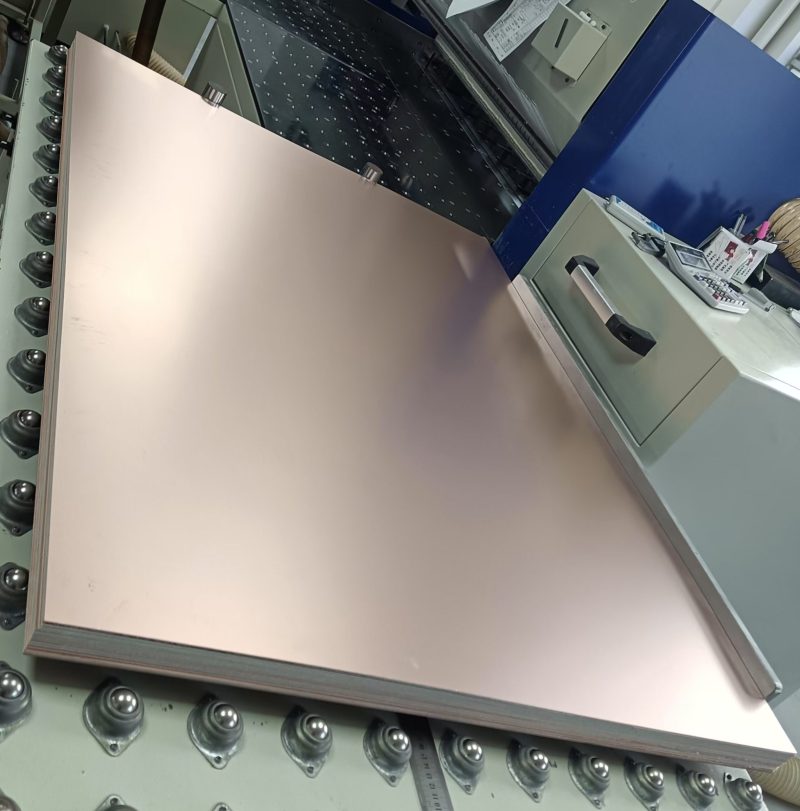

FR4 is the most widely used PCB material due to its versatility, affordability, and excellent electrical insulating properties. Made from woven fiberglass cloth and an epoxy resin, FR4 offers a balanced mix of mechanical strength and electrical performance. It is suitable for most standard applications, including consumer electronics, automotive systems, and industrial devices.

What’s the real story? FR4 offers a great cost-to-performance ratio, making it a reliable choice for most applications. It is available in a variety of thicknesses and configurations, allowing manufacturers to select the best material for their specific needs. However, for high-frequency or specialized applications, FR4 may not provide the best performance.

| FR4 Properties | Applications |

|---|---|

| Electrical Insulation | High-performance electrical insulation for most standard applications |

| Durability | Strong and resistant to heat and environmental stress |

| Cost | Economical, making it ideal for a wide range of devices |

Polyimide is a popular choice for flexible PCBs due to its excellent thermal stability, flexibility, and resistance to environmental stress. This material can withstand extreme temperatures without losing its mechanical properties, making it ideal for use in applications such as wearable electronics, automotive, and medical devices.

Ready for the good part? Polyimide’s flexibility allows it to be bent or twisted into various shapes, which is crucial for compact or flexible devices. The material also maintains its performance under harsh conditions, such as exposure to high heat or moisture, ensuring the longevity and reliability of the device. It is a go-to material for applications that demand both flexibility and performance.

| Polyimide Properties | Applications |

|---|---|

| Flexibility | Ideal for wearables, foldable devices, and tight spaces |

| Heat Resistance | Withstands high temperatures, crucial for extreme environments |

| Durability | Resistant to moisture, chemicals, and mechanical stress |

Ceramic PCBs are widely used in high-temperature applications where other materials might fail. Ceramic materials offer excellent thermal conductivity and high resistance to heat, making them ideal for use in industries such as automotive, aerospace, and power electronics. Unlike traditional materials like FR4, ceramic substrates can withstand extremely high temperatures, making them the material of choice for applications that involve power transistors or high-performance microchips.

But here’s the kicker—ceramic PCBs not only offer heat resistance but also provide superior electrical insulation. This makes them invaluable in applications where both thermal and electrical performance are crucial.

| Ceramic PCB Properties | Applications |

|---|---|

| Thermal Conductivity | Excellent heat dissipation in high-temperature environments |

| Electrical Insulation | Superior electrical properties for high-performance circuits |

| Durability | Can withstand extreme conditions, making them ideal for automotive and aerospace |

Aluminum PCBs are specifically designed for applications that require efficient heat management. The key advantage of aluminum PCBs is their ability to transfer heat away from the components, preventing overheating in high-power systems. This is particularly important in applications such as LED lighting, power supplies, and automotive electronics.

What’s the real story? Aluminum’s excellent thermal conductivity makes it a go-to material for devices that generate a significant amount of heat. In fact, aluminum PCBs can reduce the need for additional heat sinks or cooling systems, making them both cost-effective and efficient for high-power applications.

| Aluminum PCB Properties | Applications |

|---|---|

| Heat Dissipation | Excellent for high-power applications where heat management is critical |

| Cost-Effectiveness | Reduces the need for additional cooling components |

| Durability | Resistant to environmental stress and ideal for industrial use |

CEM1 and CEM3 are composite materials used for single-sided and multi-layer PCBs. These materials are similar to FR4 but typically offer lower mechanical strength and are less durable. CEM1 is a paper-based material, while CEM3 uses glass fiber for better mechanical performance. Both are popular choices for applications that don’t require the performance level of FR4 but still need reasonable strength and durability.

This is where it gets interesting: CEM1 and CEM3 are often used for consumer electronics and low-cost applications, where the cost-effectiveness of these materials outweighs the need for high-performance specifications. They offer a solid alternative to FR4 when working within a budget but still demand some level of performance and reliability.

| CEM1/CEM3 Properties | Applications |

|---|---|

| Cost-Effectiveness | Ideal for low-cost consumer electronics and simple devices |

| Strength | CEM3 offers better mechanical strength than CEM1 |

| Durability | Suitable for simple, non-complex devices but not for high-performance applications |

Environmental factors such as temperature fluctuations, humidity, and exposure to chemicals can all influence the performance and lifespan of a PCB. Materials such as polyimide and ceramic are better suited for extreme environmental conditions, whereas materials like FR4 and CEM1 may degrade faster when exposed to moisture or high temperatures.

Ready for the good part? Understanding the environmental conditions your PCB will face is essential in selecting the right material. For instance, if your PCB will be used in outdoor or high-temperature applications, you may need to opt for materials that offer superior heat resistance, such as ceramic or aluminum. These materials not only perform better under stress but also ensure that the device operates reliably throughout its lifespan.

| Environmental Factor | Impact on PCB Material |

|---|---|

| Temperature | Materials like polyimide and ceramic are better for high-temperature environments |

| Humidity | Materials like FR4 can degrade under high moisture conditions |

| Chemical Exposure | Certain materials offer better resistance to chemicals and harsh environments |

The material used for PCBs can significantly impact both production time and cost. Materials like FR4 and CEM1 are relatively inexpensive and widely available, making them ideal for mass production. However, more specialized materials, such as Rogers and ceramic, can be much more costly and may require more time to source and manufacture.

What’s the real story? It’s essential to balance material costs with performance requirements. While it might be tempting to choose the least expensive material, opting for higher-performance materials could save costs in the long run by increasing the reliability and lifespan of the product.

| Material Cost | Characteristics |

|---|---|

| Low-Cost Materials (FR4, CEM1) | Ideal for budget-friendly, high-volume production |

| High-Cost Materials (Rogers, Ceramic) | Provide superior performance, but at a higher cost |

Q1: What factors should be considered when choosing PCB materials?

A1: Factors like electrical performance, thermal management, mechanical strength, and environmental conditions must be considered when selecting the right PCB material.

Q2: Why is FR4 the most common PCB material?

A2: FR4 is widely used due to its cost-effectiveness, strong mechanical properties, and good electrical insulation, making it suitable for a wide range of applications.

Q3: How does polyimide compare to FR4 for flexible PCBs?

A3: Polyimide offers superior flexibility and heat resistance, making it ideal for flexible PCBs used in wearable electronics, while FR4 is rigid and not suitable for such applications.

Q4: What are the advantages of using ceramic PCBs?

A4: Ceramic PCBs offer excellent thermal conductivity and electrical insulation, making them ideal for high-temperature and high-power applications like automotive and aerospace.

Q5: How do environmental factors affect PCB material selection?

A5: Environmental factors such as temperature, humidity, and chemical exposure can degrade certain materials, making it important to choose materials suited to the specific conditions your PCB will face.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote