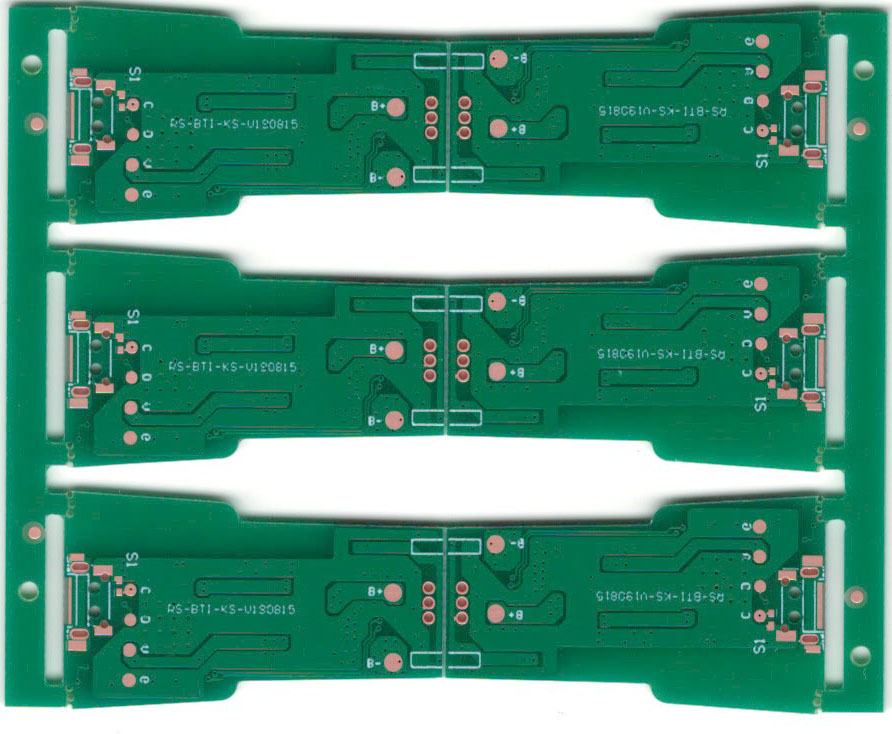

Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

PCBSupplier: Your Ultimate Guide to Choosing the Best Manufacturer

When it comes to electronics manufacturing, choosing the right PCB supplier is critical. A reliable PCB supplier ensures that the circuit boards are designed and produced to meet specific requirements, making them essential for the success of any electronic device. But here’s the kicker: not all PCB suppliers are created equal. From cost to quality and reliability, finding the right supplier can make or break your project. This article will guide you through the key aspects of selecting the best PCB supplier, including the factors to consider, the services offered, and common mistakes to avoid. Ready to dive in? Let’s explore the world of PCB suppliers.

PCBSupplier

What’s the real story? A PCB supplier plays a pivotal role in the manufacturing process, bridging the gap between design and final product. They are responsible for fabricating the circuit boards, ensuring that the design specifications are met, and often provide assembly services as well. A supplier’s responsibilities include selecting the right materials, producing the PCB layout, and managing the production process from start to finish. In some cases, they may even assist with testing and validation to ensure the board works as intended.

But here’s the kicker: the role of a PCB supplier doesn’t end with just production. The best suppliers will also provide design support, helping you optimize your design for manufacturability and identifying potential issues before they arise. They will collaborate closely with your engineering team to ensure the boards are both cost-effective and high-quality, which is especially important in complex applications like medical devices or high-speed communication systems.

| Service Type | Description | Examples of Use Cases |

|---|---|---|

| Design Support | Assisting with PCB layout and design optimization | High-performance circuits |

| Prototyping | Creating prototypes for testing and validation | New product development |

| Full-Scale Manufacturing | Mass production of PCBs with high-volume needs | Consumer electronics, automotive |

| Assembly | Attaching components to PCBs during production | IoT devices, medical devices |

What’s the real story? The PCB supplier market is diverse, and there are several types of suppliers to choose from, each with its own strengths and focus areas. Let’s break it down:

But here’s the kicker: knowing what type of PCB supplier is right for your needs is crucial. Choose an OEM supplier if you require end-to-end support, opt for an EMS supplier for cost-effective mass production, or work with a specialized PCB supplier for advanced, niche applications.

| Supplier Type | Services Offered | Ideal for |

|---|---|---|

| OEM Suppliers | Complete end-to-end PCB services | Large-scale manufacturing |

| EMS Suppliers | PCB manufacturing and assembly | Cost-effective, high volume |

| Specialized PCB Suppliers | Specialized designs (flex, HDI, RF) | Advanced, niche applications |

Ready for the good part? Selecting the right PCB supplier involves a careful evaluation of several key factors. Let’s break down what you need to consider when making your decision:

What’s the kicker? By considering these factors, you can select a supplier that aligns with your project goals, budget, and quality requirements, ensuring a smooth and successful collaboration.

| Factor | Importance | What to Look For |

|---|---|---|

| Lead Time | Ensures timely delivery | Clear, realistic timelines |

| Quality Standards | Guarantees product reliability and performance | ISO, UL, RoHS certifications |

| Pricing | Affects project cost | Fair pricing with high value |

| Communication & Support | Impacts collaboration and problem-solving | Responsiveness, helpful support |

What’s the real story? When selecting a PCB supplier, it’s essential to understand the range of services they offer. From design and prototyping to full-scale manufacturing and assembly, the best suppliers offer a comprehensive suite of services that cater to different stages of the production process. Let’s take a look at some of the core services that PCB suppliers typically offer:

What’s the kicker? By choosing a supplier that offers a full range of services, you can streamline your PCB development process, saving time and reducing the risk of errors.

| Service Type | Description | Ideal for |

|---|---|---|

| Design Support | Assistance with PCB design optimization | Complex, high-performance boards |

| Prototyping | Quick-turn prototyping for design validation | Early-stage product development |

| Manufacturing | Full-scale production of PCB boards | High-volume manufacturing |

| Assembly | Component placement and final assembly | Turnkey solutions for ready-to-use products |

What’s the real story? Quality control is non-negotiable in PCB manufacturing. The best PCB suppliers adhere to stringent quality control measures and hold various certifications that prove their commitment to quality. Here’s what to look for:

What’s the kicker? When selecting a PCB supplier, prioritize those with the necessary certifications and robust quality control systems to guarantee the best possible product.

| Certification | Purpose | Industry Relevance |

|---|---|---|

| ISO | Ensures consistent quality management | General manufacturing |

| UL | Ensures safety compliance and standards | Automotive, medical |

| RoHS | Restricts hazardous substances in electronics | Environmental compliance |

| AOI | Detects manufacturing defects and ensures quality | Electronics, automotive |

What’s the real story? Pricing is a key consideration when choosing a PCB supplier, but it’s important to understand that the cheapest option isn’t always the best. Here’s what you need to know about PCB pricing and the factors that influence it:

What’s the kicker? Understanding these pricing factors can help you make an informed decision about your PCB supplier and get the best value for your money.

| Factor | Impact on Cost | Cost Control Tip |

|---|---|---|

| Material | High-performance materials cost more | Choose cost-effective materials where possible |

| Design Complexity | Complex designs increase cost | Optimize design for manufacturability |

| Order Volume | Larger orders reduce cost per unit | Order in bulk for savings |

| Lead Time | Faster lead times increase cost | Plan ahead to avoid rush orders |

Ready for the good part? Lead time is one of the most important factors when selecting a PCB supplier. Timely delivery can ensure that your product gets to market faster, which is especially important in industries like consumer electronics and automotive. Here’s what you need to know:

What’s the kicker? Work with suppliers who offer reliable lead times and communicate openly about any potential delays to avoid last-minute surprises.

| Lead Time Type | Description | Impact on Cost |

|---|---|---|

| Standard | 5-15 days for typical orders | Lower cost |

| Expedited | 48-hour turnaround for urgent orders | Additional premium charge |

| International Delivery | Shipping times from overseas suppliers | May increase overall lead time |

What’s the real story? Communication is key to a successful partnership with your PCB supplier. A supplier with strong communication and support services can help resolve issues quickly, keeping your project on track. Here’s what to look for:

What’s the kicker? Choosing a supplier with strong communication channels ensures a smooth workflow and reduces the risk of delays or misunderstandings.

| Support Type | Importance | What to Look For |

|---|---|---|

| Response Time | Ensures timely resolution of issues | Fast, clear communication |

| Technical Support | Helps optimize designs and troubleshoot | In-house engineering team |

| After-Sales Support | Resolves issues with final products | Dedicated support services |

What’s the real story? PCB prototyping is a crucial service offered by PCB suppliers that allows you to test your design before mass production. Prototypes help identify potential issues early, saving both time and money. Here’s why prototyping is essential:

What’s the kicker? With prototyping services, you can minimize the risk of errors in the final production and ensure that your product works as expected.

| Prototyping Service | Description | Benefits |

|---|---|---|

| Quick-Turn | Rapid prototyping services | Fast feedback on designs |

| Design Validation | Testing for functionality and performance | Identifying issues early |

| Iterative Prototyping | Making revisions based on testing results | Ensures optimal design |

What’s the kicker? Quality assurance and testing are essential to ensuring that your PCB performs as expected and meets all standards. The best PCB suppliers implement stringent testing procedures to guarantee the reliability and functionality of their boards. Here’s how it’s done:

What’s the real story? Testing ensures that your PCB will work reliably and efficiently, reducing the likelihood of failures down the line.

| Test Type | Purpose | Importance |

|---|---|---|

| AOI (Automated Optical Inspection) | Detects visual defects in the PCB | Ensures high-quality manufacturing |

| Electrical Testing | Verifies electrical functionality | Identifies circuit issues |

| Functional Testing | Simulates real-world use of the PCB | Confirms design performance |

What’s the kicker? When it comes to pricing, understanding the factors that influence the cost of your PCB is crucial. The primary factors include material costs, design complexity, order volume, and lead time. Here’s how they affect your budget:

What’s the kicker? By understanding these cost factors, you can make informed decisions that keep your project within budget without compromising on quality.

| Factor | Description | Impact on Price |

|---|---|---|

| Material | Choice of substrate and components | Higher-end materials cost more |

| Design Complexity | Complexity of design and features | More complex designs cost more |

| Order Volume | Number of units ordered | Larger orders reduce cost per unit |

| Lead Time | Speed of production and delivery | Faster delivery increases price |

Ready for the good part? Lead time is one of the most critical factors when selecting a PCB supplier, especially for time-sensitive projects. Here’s what to consider:

What’s the kicker? Selecting the right lead time option ensures that your PCBs arrive on time, keeping your production schedule on track and preventing costly delays.

What’s the real story? Strong communication with your PCB supplier ensures a smooth process from design to delivery. Suppliers that offer responsive and effective support are invaluable for troubleshooting issues and keeping your project on track. Here’s what to look for:

What’s the kicker? By working with a supplier that offers strong communication and support, you ensure a smoother production process and more successful project outcomes.

| Support Type | Importance | What to Look For |

|---|---|---|

| Responsive Communication | Ensures quick resolutions to issues | Fast email and phone responses |

| Customer Support | Assists with design and manufacturing queries | Dedicated, knowledgeable staff |

| Post-Sales Support | Helps with any post-production issues | Warranty, troubleshooting assistance |

What’s the kicker? Choosing the right PCB supplier is critical to the success of your project. By considering factors like lead time, cost, quality control, and communication, you can select a supplier that aligns with your needs. Keep in mind that a reliable supplier is more than just a manufacturer—they are a partner who helps bring your product to life. Ensure you make an informed decision, and the right PCB supplier will play a key role in your project’s success.

Q1: What is a PCB supplier?

A PCB supplier is a company that provides manufacturing and assembly services for printed circuit boards, from design to final production.

Q2: How does PCB manufacturing work?

PCB manufacturing involves designing, fabricating, and assembling circuit boards, which includes creating the layout, etching copper, and attaching components.

Q3: What factors should I consider when choosing a PCB supplier?

Consider lead time, cost, quality standards, certifications, and customer support when choosing a PCB supplier.

Q4: How can I reduce the cost of my PCB orders?

Optimize your design for manufacturability, order in bulk, and choose materials that meet your needs without over-specifying.

Q5: How do I ensure the quality of my PCBs?

Choose a supplier with strong quality control processes, certifications, and a proven track record of delivering high-quality products.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote