Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

Rigid PCB boards are the foundation of modern electronics, providing stability and reliability for countless devices. But what makes them so indispensable? Let’s explore their features, manufacturing process, and diverse applications in detail.

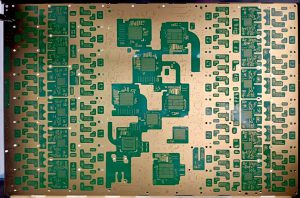

Rigid PCB Board

A rigid PCB is a solid, inflexible circuit board that provides mechanical support for electronic components. Here’s the key point: Unlike flexible PCBs, these boards maintain their shape under stress, making them ideal for demanding environments.

The most common materials include FR4 fiberglass, aluminum, and ceramic substrates. These materials offer excellent thermal and electrical properties while ensuring durability. Single-layer designs work for simple circuits, while complex applications may require multi-layer configurations with 20+ layers.

But here’s something interesting: The glass transition temperature (Tg) of the material determines how well the board withstands heat. High-Tg materials (170°C+) are essential for automotive and industrial uses where temperatures fluctuate dramatically.

| Property | Rigid PCB | Flexible PCB |

|---|---|---|

| Material | FR4, metal core | Polyimide |

| Flexibility | None | High |

| Cost | Lower for simple designs | Higher due to specialized materials |

| Best For | High-power applications | Compact, bendable devices |

The production process involves multiple precision steps. What’s fascinating is how these steps have evolved with automation while maintaining strict quality standards.

It all begins with the design phase using CAD software, where engineers layout the circuit pattern. Next comes the imaging process, where the design gets transferred to the board using photoresist chemicals. The etching stage then removes excess copper, leaving only the desired circuit traces.

Here’s a critical detail: Drilling accuracy is paramount, especially for multi-layer boards where alignment affects performance. Modern laser drilling achieves holes as small as 0.1mm in diameter. The final steps include solder mask application, silkscreen printing, and surface finishing like HASL or ENIG.

These boards offer distinct advantages that make them preferred for many applications. The real game-changer is their ability to handle high power and heat without compromising performance.

Key characteristics include:

Here’s an important note: The flat, rigid surface allows for easier automated assembly compared to flexible alternatives. This significantly reduces manufacturing costs for high-volume production.

These boards are everywhere in modern technology. You might be surprised to learn they’re in devices you use daily.

In consumer electronics, they form the backbone of:

The automotive industry relies on them for:

Industrial applications include:

Choosing rigid PCBs offers several benefits. Here’s why engineers prefer them:

First, they’re cost-effective for mass production. The materials are readily available, and the manufacturing process is well-established. Second, they provide better heat dissipation than flexible alternatives, crucial for power electronics.

But there’s more: Their dimensional stability ensures components stay perfectly aligned, which is vital for high-frequency applications. The robust construction also makes them easier to test and repair compared to flexible circuits.

While versatile, these boards have limitations. The main drawback is their lack of flexibility, which restricts design options.

Other challenges include:

Here’s something to consider: In applications requiring both rigid and flexible sections, rigid-flex PCBs provide a hybrid solution that combines the best of both technologies.

Understanding the differences helps in selecting the right solution. The choice ultimately depends on your specific application requirements.

Rigid PCBs excel in:

Flexible PCBs are better for:

Key takeaway: Many modern devices actually use both types, with rigid boards for the main circuitry and flexible ones for interconnects.

Several variations exist to meet different needs. You’ll be interested to know how these types serve distinct purposes.

Single-layer boards are the simplest and most economical, suitable for basic electronics. Double-layer designs allow for more complex circuits by utilizing both sides. Multi-layer configurations (4-20+ layers) enable high-density interconnects for advanced applications.

Specialized types include:

Selecting the appropriate board requires careful consideration. Here’s what really matters in the decision process.

First, assess your electrical requirements – current, voltage, and signal frequency. Next, consider the operating environment – temperature range, humidity, and potential exposure to chemicals. Mechanical factors like vibration and shock resistance are equally important.

Pro tip: Work closely with your PCB manufacturer early in the design phase. Their expertise can help optimize your design for manufacturability and cost-effectiveness.

Even experienced engineers can make errors. Avoid these pitfalls to ensure a successful design.

Common issues include:

Critical reminder: Always perform design rule checks (DRC) and consider doing a prototype run before full-scale production.

Quality assurance is crucial. Modern testing methods can catch defects early.

Automated Optical Inspection (AOI) scans for surface defects, while flying probe testing checks electrical connectivity. For complex boards, X-ray inspection verifies internal layer alignment and solder joint quality.

Don’t overlook: Environmental stress testing that simulates real-world conditions to ensure long-term reliability.

The industry continues to evolve. Here’s what’s shaping the future of rigid PCBs.

Miniaturization drives demand for higher density interconnects. New materials like low-loss laminates improve high-frequency performance. Embedded components within the PCB layers save space and enhance performance.

Exciting development: The integration of rigid PCBs with advanced packaging technologies like system-in-package (SiP) solutions.

Proper care extends their lifespan. Follow these best practices for maintenance.

Regular cleaning removes dust and contaminants that could cause shorts. Use proper ESD precautions when handling. For repairs, identify faulty components using diagnostic tools and replace them using proper soldering techniques.

Important note: Some multilayer boards may be impractical to repair and are better replaced entirely.

Despite new technologies, rigid PCBs remain vital. Here’s why they’ll continue to be essential.

Emerging applications in 5G infrastructure, electric vehicles, and renewable energy systems all rely on rigid PCB technology. Material innovations will further improve their performance and reliability.

Final thought: While flexible electronics grow in popularity, rigid PCBs will maintain their dominant position in electronics manufacturing.

Choosing the right supplier is crucial. Consider these factors when selecting a vendor.

Look for manufacturers with:

Pro advice: Request samples and conduct thorough testing before committing to large orders.

Q1: What is the typical lifespan of a rigid PCB?

With proper design and use, rigid PCBs can last 10-20 years in normal operating conditions.

Q2: Can rigid PCBs be used in high-frequency applications?

Yes, especially when using specialized high-frequency laminates with controlled dielectric properties.

Q3: How many layers can a rigid PCB have?

While most have 1-12 layers, advanced boards can have up to 50 layers for super-complex applications.

Q4: Are rigid PCBs recyclable?

Yes, though the process is complex due to the mix of materials. Specialized recycling facilities can recover valuable metals.

Q5: What’s the lead time for custom rigid PCBs?

Typically 1-4 weeks depending on complexity, layer count, and the manufacturer’s workload.

This comprehensive guide covers all aspects of rigid PCB technology. Now you have the knowledge to make informed decisions about these essential components. For specific applications, consult with PCB design experts to optimize your solution.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote