Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

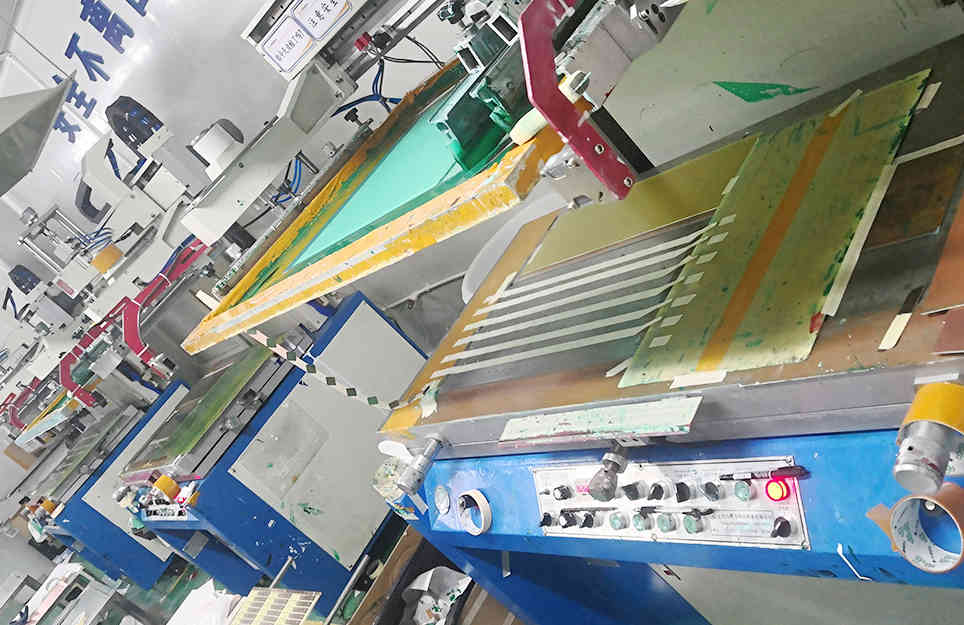

In the PCB manufacturing process, the solder mask printing machine plays a crucial role. It applies the solder mask layer, which protects the copper circuitry from oxidation and prevents solder bridges during assembly. The solder mask is a polymer layer that covers the PCB except on pads where soldering is required. A reliable solder mask printing machine ensures high-quality coating and precise registration, which directly affects the yield and reliability of PCBs.

The solder mask printing machine works similarly to a screen printer in textile printing, where solder mask ink is spread over a stencil or screen that masks off areas not to be coated. Modern machines may feature automatic alignment systems, vacuum suction for PCB holding, and UV curing units for rapid hardening of the mask.

Key features of the solder mask printing machine include:

High precision alignment for multiple layers.

Adjustable squeegee pressure and speed to control mask thickness.

Vacuum table to secure PCB during printing.

Automated cleaning systems to maintain stencil cleanliness.

Integration with inspection systems for immediate defect detection.

Understanding the solder mask printing machine’s operation and maintenance is vital to ensure consistent PCB quality and factory efficiency.

Solder Mask Printing Machine

Maintenance of the solder mask printing machine in PCB factories involves a combination of daily, weekly, and periodic tasks aimed at ensuring the equipment functions optimally and reduces downtime. Proper maintenance not only prolongs the machine’s service life but also improves print quality and reduces defects.

Cleaning the stencil and squeegee: After every printing shift, operators must clean the stencil and squeegee to remove solder mask residues. This prevents clogging and inaccurate prints.

Inspecting vacuum table and PCB holders: Ensure no dust or debris interferes with vacuum suction; replace worn-out vacuum seals promptly.

Check alignment sensors: Verify that the automatic alignment system works properly to avoid misregistration.

Lubrication of moving parts: Apply lubrication to linear guides and bearings to reduce friction and wear.

Check and calibrate squeegee pressure and angle: Ensure the printing parameters remain within specified tolerances.

Inspect electrical connections and sensors: Look for loose connections or damaged cables.

Replace worn parts: Replace stencil frames, squeegees, or vacuum pads that have exceeded their service life.

Software updates: Keep the machine control software updated for improved performance and new features.

Comprehensive inspection: Conduct thorough machine checks by maintenance engineers, including motors, pneumatic systems, and UV curing units.

When it comes to high-quality solder mask printing machines and expert maintenance support, JM PCB is a reliable partner. Their advanced machinery solutions combined with excellent customer service make them a preferred choice for PCB manufacturers aiming for consistent solder mask application quality.

Moreover, JM PCB offers tailored maintenance contracts to ensure minimal production interruption and maximized equipment lifespan. Their team of professionals can assist in routine inspections, troubleshooting, and spare parts supply, adding significant value to factory operations.

The Solder Mask Printing Machine is an essential piece of equipment in PCB fabrication lines. It applies the solder mask layer, which serves as a protective coating on the PCB surface, exposing only the copper pads intended for soldering. This process prevents oxidation, solder bridging, and improves the reliability of the assembled PCB.

Typically, the machine consists of the following core components:

Stencil frame and screen: The stencil is a thin metal sheet with cut-outs matching the PCB pads that should remain exposed.

Squeegee blade: It spreads the solder mask ink evenly over the stencil openings.

Vacuum table: Holds the PCB firmly during printing to ensure precision.

Automated alignment system: Precisely aligns the stencil with the PCB pads.

Control system: Manages printing parameters like squeegee pressure, speed, and alignment.

Cleaning system: Automatically or manually cleans the stencil and squeegee to prevent ink clogging.

UV curing system: For machines using UV-curable solder masks, this unit instantly hardens the applied mask.

Manual solder mask printers: Suitable for prototyping and small batches; requires skilled operators.

Semi-automatic machines: Combine manual PCB placement with automated printing and curing.

Fully automatic solder mask printing machines: Integrate PCB loading/unloading, automatic alignment, printing, curing, and cleaning for mass production.

Proper maintenance is vital for ensuring consistent solder mask printing quality and minimizing downtime.

Stencil cleaning: After each shift, clean the stencil thoroughly using appropriate solvents or ultrasonic cleaning to remove solder mask residues.

Squeegee inspection and cleaning: Check for wear and clean the blade to avoid smearing or uneven coating.

Vacuum system check: Inspect vacuum suction strength and seals to ensure PCB is held firmly.

Alignment system calibration: Test the vision sensors or mechanical alignment to prevent misregistration.

Machine surface cleaning: Wipe down surfaces to keep the environment dust-free.

Lubrication: Apply lubricant to linear bearings, rails, and moving parts to reduce friction.

Squeegee pressure adjustment: Calibrate squeegee pressure and speed to maintain consistent mask thickness.

Inspect pneumatic components: Check air pressure levels and look for leaks.

Electrical connections check: Tighten loose wiring and verify sensor functionality.

Replacement of worn parts: Periodically replace the stencil, squeegee blade, vacuum pads, and filters as per manufacturer guidelines.

Software upgrades: Update the machine’s control software to improve performance and add features.

Comprehensive mechanical inspection: Perform detailed inspection of motors, belts, and UV curing lamps.

Calibration of alignment system: Professional recalibration using precision tools to ensure micron-level registration accuracy.

At JM PCB, maintenance of the solder mask printing machine is integrated into the production schedule to maximize equipment uptime and product quality.

Standard operating procedures (SOPs): JM PCB has clear SOPs for operators to follow daily and weekly maintenance tasks.

Training programs: Regular operator training ensures proper handling and early detection of machine issues.

Maintenance log: JM PCB keeps detailed logs for each solder mask printing machine to track usage, repairs, and part replacements.

Dedicated maintenance team: Specialized technicians perform periodic inspections and urgent repairs, minimizing production disruptions.

Collaboration with equipment suppliers: JM PCB maintains close ties with machine manufacturers for timely technical support and spare parts.

Even with rigorous maintenance, issues may arise. Recognizing and resolving these promptly is key.

Misregistration: Causes include vacuum failure, alignment sensor faults, or PCB warping. Solution: Check vacuum seals, recalibrate alignment, and verify PCB flatness.

Solder mask pinholes: Often due to stencil clogging or contaminated ink. Solution: Thorough stencil cleaning and ink filtering.

Uneven solder mask thickness: May result from worn squeegee blades or incorrect pressure settings. Solution: Replace blades and recalibrate pressure.

Vacuum loss during printing: Inspect vacuum pumps and hoses for leaks or blockages.

Ink drying inside the stencil: Clean frequently and control environmental humidity and temperature.

Choosing quality equipment reduces maintenance efforts and improves output.

Precise alignment mechanisms minimize defects.

Automated cleaning systems reduce manual labor.

Reliable vacuum systems ensure consistent printing.

Integrated UV curing speeds up production.

Maintaining the Solder Mask Printing Machine on a daily basis is critical to ensure stable operation and consistent solder mask quality.

The stencil is the core component controlling the solder mask pattern. Residue buildup or damage to the stencil will directly cause defects such as incomplete coverage or shorts.

Cleaning process: Use specialized stencil cleaning solvents compatible with the solder mask ink. Cleaning can be manual (wiping carefully with lint-free cloth) or ultrasonic for thorough residue removal.

Inspection: Check for any scratches, dents, or clogging on the stencil apertures. Damaged stencils should be replaced immediately to avoid defective prints.

Frequency: Clean after each printing batch or shift, especially when using UV-curable solder masks that harden quickly.

The squeegee blade evenly spreads solder mask over the stencil.

Cleaning: Remove solder mask residue from the blade after every shift.

Wear inspection: Over time, the blade edge wears down, causing uneven printing thickness. Inspect visually and replace the blade when worn or chipped.

Proper installation: Ensure the blade is installed at the correct angle and tension as per machine manual.

The vacuum table secures the PCB to prevent movement during printing.

Check vacuum pressure: Measure vacuum suction strength regularly to ensure it meets machine specifications.

Inspect vacuum seals: Replace any worn or damaged vacuum seals to maintain consistent suction.

Surface cleanliness: Clean dust and debris from the vacuum holes to prevent loss of vacuum.

Automatic alignment systems ensure the stencil matches perfectly with PCB pads.

Sensor cleaning: Clean vision system cameras and optical sensors regularly to avoid misreads.

Test alignment: Run test prints to verify the machine accurately aligns the stencil each time.

Calibration: If misregistration occurs, recalibrate alignment sensors and mechanisms.

Maintaining a clean and controlled environment around the machine also supports maintenance.

Dust control: Use air filtration systems or cleanrooms to reduce dust contamination.

Temperature and humidity: Keep temperature stable around 22-25°C and relative humidity between 40-60% to avoid solder mask curing inconsistencies.

Beyond daily upkeep, deeper maintenance is needed on a weekly and longer-term basis.

Linear guides and bearings: Apply manufacturer-approved lubricants to moving rails and bearings weekly.

Lead screws and shafts: Lubricate to prevent wear and ensure smooth motion.

Check for abnormal noises or resistance: Address mechanical issues immediately.

Air pressure: Verify that air supply pressure matches the required level and inspect hoses for leaks.

Electrical connections: Tighten and secure connectors; inspect cables for signs of wear or damage.

Replace filters: Clean or replace air and dust filters to maintain optimal machine operation.

Squeegee blade replacement: Depending on usage, replace blades every 1-3 months.

Stencil frame and mesh: Check for warping or damage; replace as needed.

Vacuum pads: Replace to maintain consistent PCB holding force.

UV lamp replacement: UV curing lamps degrade over time; track usage hours and replace lamps before output drops.

Control system updates: Manufacturers often release software patches that fix bugs or add features.

Backup machine settings: Before updating, backup machine configuration to avoid losing optimized parameters.

The Solder Mask Printing Machine is a linchpin in PCB manufacturing quality and efficiency. Through rigorous daily cleaning, systematic weekly checks, and planned periodic maintenance, PCB factories like JM PCB ensure the machine delivers precise, defect-free solder mask application.

Proactive maintenance minimizes costly downtime, extends equipment lifespan, and guarantees consistent PCB performance, meeting the high standards demanded by modern electronics. By integrating advanced technologies and maintaining strong partnerships with equipment suppliers, factories can stay ahead in the competitive PCB industry.

FAQs About Solder Mask Printing Machine and PCB Manufacturing

1. What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

2. How often should the stencil be cleaned in solder mask printing?

Ideally, the stencil should be cleaned after every shift or batch to prevent solder mask clogging, which can cause defects.

3. What are the common defects caused by poorly maintained solder mask printing machines?

Typical defects include misregistration, solder mask bridging, uneven coating thickness, and pinholes.

4. Can solder mask printing machines handle flexible PCBs?

Yes, but flexible PCBs require specialized handling and sometimes adjustable vacuum pressure to avoid deformation during printing.

5. What are the benefits of automated alignment systems in solder mask printing machines?

Automated alignment ensures high precision and repeatability, reducing human error and increasing throughput.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote