Well-known PCB supplier

Well-known PCB supplier

+86 13603063656

Special PCB Board: Exploring Unique Designs and Applications

Special PCBs are the backbone of many modern electronics, offering custom solutions to meet the specific needs of various industries. Unlike standard PCBs, special PCBs are designed for high-performance applications, incorporating advanced materials, specialized features, and complex configurations. These boards are used in a wide range of industries, including automotive, aerospace, telecommunications, and medical devices. But here’s the kicker: selecting the right special PCB board can dramatically improve your product’s performance, reliability, and overall success. This article dives into the unique characteristics of special PCBs, the challenges involved in their design and manufacturing, and the vast array of applications they support. Ready for the good part? Let’s explore how special PCBs can transform your electronic products.

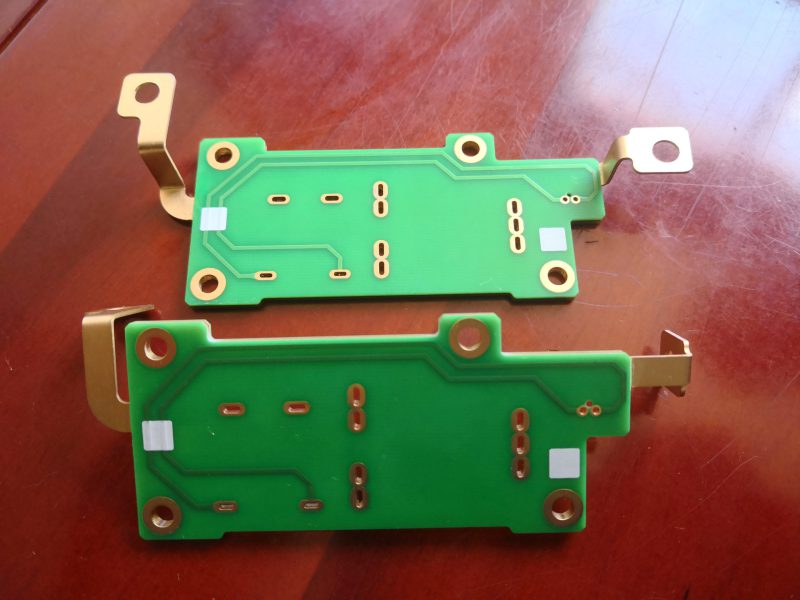

Special PCB Board

What’s the real story? Special PCBs come in many forms, each designed to meet unique demands in terms of performance, reliability, and size. These boards are typically more complex than standard PCBs and require careful consideration during design and manufacturing. Let’s explore the most common types of special PCBs:

But here’s the kicker: each type of special PCB is designed for a specific purpose and selecting the right one for your project requires a deep understanding of your application’s needs. Whether you need flexibility, high-speed performance, or heat management, special PCBs offer the tailored solutions to get the job done.

| Type of PCB | Characteristics | Ideal Use Cases |

|---|---|---|

| Flexible PCBs | Made from flexible materials like polyimide | Wearable devices, cameras, foldable electronics |

| Rigid-Flex PCBs | Combines rigid and flexible PCB features | Smartphones, medical devices, aerospace |

| High-Frequency PCBs | Designed for high-speed and RF signal transmission | Communication systems, GPS, wireless networks |

| HDI PCBs | Higher component density and faster signal transmission | Smartphones, tablets, IoT devices |

| Aluminum PCBs | Metal base for heat dissipation | Power electronics, LED lights, high-power applications |

What’s the real story? Special PCBs are found in virtually every modern electronic device, from smartphones to advanced medical equipment. Their unique designs and features make them essential in applications that demand high performance, compactness, and reliability. Let’s take a closer look at the industries that rely on special PCBs:

What’s the kicker? No matter the industry, special PCBs enable the development of innovative products that push the boundaries of what’s possible in electronics, ensuring high performance, compact design, and reliability in the most demanding applications.

| Industry | Application Examples | Key Benefits |

|---|---|---|

| Consumer Electronics | Smartphones, tablets, wearables, gaming consoles | Compact design, high performance |

| Automotive | ECUs, sensors, infotainment systems | Durability, high performance |

| Medical Devices | Diagnostic equipment, wearable health devices | Reliability, miniaturization |

| Telecommunications | Network infrastructure, wireless systems | High-speed data transmission |

| Power Electronics | Power supplies, lighting, motor control | Efficient heat dissipation |

What’s the real story? Designing special PCBs comes with its own set of challenges. Unlike standard PCBs, special PCBs require careful consideration of factors like material selection, thermal management, and signal integrity. Let’s dive into the most common design challenges:

What’s the kicker? While designing special PCBs can be challenging, working with an experienced PCB supplier and carefully considering design, materials, and manufacturability can help overcome these hurdles and ensure a successful final product.

| Challenge | Description | Solution |

|---|---|---|

| Material Selection | Choosing the right material for specific applications | Work with experienced suppliers |

| Thermal Management | Managing heat dissipation in high-power applications | Use heat sinks, copper-filled vias |

| Design Complexity | More complex designs increase the risk of errors | Optimize design for manufacturability |

| Manufacturing Limitations | Advanced techniques may not be available at all factories | Choose a supplier with specialized capabilities |

What’s the kicker? Special PCBs offer a wide range of benefits over standard PCBs, making them the go-to solution for applications that require high performance, reliability, and compactness. Let’s take a closer look at the advantages:

What’s the kicker? The benefits of special PCBs make them indispensable in industries where performance, space constraints, and reliability are key factors. Whether you need flexibility, high-density designs, or enhanced thermal management, special PCBs offer the ideal solution.

| Benefit | Explanation | Application Examples |

|---|---|---|

| Flexibility and Durability | Ability to bend, twist, and fold without breaking | Wearables, flexible electronics |

| Higher Component Density | Allows more components in a smaller space | Smartphones, tablets |

| Improved Signal Integrity | Minimizes signal loss and interference | Communication systems, RF circuits |

| Efficient Heat Dissipation | Prevents overheating in high-power applications | Power supplies, LED lighting |

What’s the real story? The choice of materials plays a crucial role in the performance of special PCBs. Different materials offer unique benefits, making it important to choose the right one for your application. Let’s take a look at some of the key materials used in special PCBs:

What’s the kicker? The right material choice ensures that your PCB performs as expected in terms of signal integrity, flexibility, and heat management, contributing to the overall success of your electronic device.

| Material | Characteristics | Ideal Use Cases |

|---|---|---|

| High-Frequency Laminates | Minimizes signal loss, high dielectric properties | RF circuits, communication systems |

| Flexible Substrates | Allows bending and flexibility | Wearables, medical devices |

| Copper | Conductive, varies in thickness | Power electronics, general PCBs |

| Heat-Resistant Materials | Withstands high temperatures, effective heat dissipation | Power supplies, high-power devices |

Q1: What is a special PCB board?

A special PCB board is a customized circuit board designed to meet unique performance, size, or flexibility requirements for specific applications.

Q2: How does the design of special PCBs differ from standard PCBs?

Special PCBs often incorporate advanced materials, multiple layers, or specialized features to meet the specific demands of high-performance applications.

Q3: What are the common applications of special-PCB boards?

Special PCBs are used in industries such as consumer electronics, automotive, medical devices, telecommunications, and power electronics, where high performance and reliability are critical.

Q4: What materials are used in special PCBs?

Special PCBs often use materials like high-frequency laminates, flexible substrates, copper, and heat-resistant materials to achieve desired performance characteristics.

Q5: What are the benefits of using special-PCB boards?

The benefits of special PCBs include enhanced flexibility, higher component density, improved signal integrity, and efficient heat dissipation, making them ideal for complex electronic applications.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote