When it comes to electronics manufacturing, understanding PCB board price is not just about checking a number on a quote. It’s about knowing what goes into that number and how you can influence it to save costs without compromising quality. For engineers, procurement managers, and OEM buyers, PCB pricing affects everything from R&D budgets to production timelines. But here’s the kicker… one simple design change could either slash your cost or double it. In this guide, we’ll explore the factors behind PCB board price, how manufacturers calculate it, and what you can do to get the best value in the B2B world.

PCB Board Price

PCB board price is one of the most critical line items in any electronics product budget. For B2B buyers, especially in sectors like IoT, automotive, medical, and industrial automation, understanding how prices are formed can lead to better supplier negotiations and smarter project planning.

But what’s the real story? Many professionals still rely on ballpark figures without fully grasping the cost breakdown. And that’s where profit leaks happen. Whether you’re working on a prototype or a production run, each layer, via, or surface finish has a price tag tied to it.

So this article isn’t just about numbers—it’s a blueprint for decision-makers who want to maximize ROI from their PCB sourcing strategy. We’ll dig into materials, complexity, finishes, order volumes, and more—all the variables that impact cost, quality, and delivery timelines.

| Industry | PCB Cost Sensitivity | Typical PCB Layer Count | Typical Volume Order |

|---|---|---|---|

| Consumer | High | 2–6 layers | Large |

| Automotive | Medium | 4–10 layers | Medium |

| Medical | Very High | 6–12 layers | Low/Medium |

| Industrial | Medium | 4–8 layers | Medium/Large |

| Aerospace | Very High | 8+ layers | Small |

A Printed Circuit Board (PCB) is the backbone of all modern electronics. It’s a flat, rigid structure made of insulating material layered with conductive copper. These copper tracks allow electricity to flow between components like resistors, ICs, and connectors.

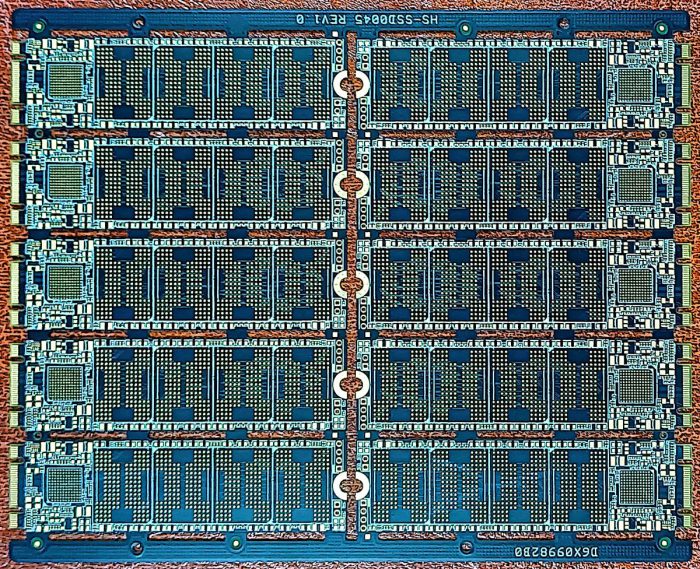

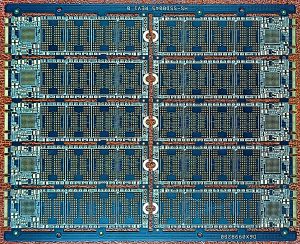

But here’s where it gets interesting… The way a PCB is built—single-sided, double-sided, or multilayer—directly influences not just its performance, but also its cost. Each layer added increases material consumption, fabrication complexity, and inspection requirements.

In a B2B setting, whether you’re designing a wearable fitness tracker or an industrial control unit, understanding how the board structure impacts PCB board price is fundamental. Knowing what you need and what you can compromise on can save you thousands of dollars over the life of a product.

| PCB Type | Description | Typical Cost (per unit) |

|---|---|---|

| Single-Sided | Copper on one side only | $0.10–$1.00 |

| Double-Sided | Copper on both sides | $0.50–$3.00 |

| Multilayer (4–8) | 4–8 conductive layers | $3.00–$20.00 |

| HDI | High-density interconnect | $10.00–$100.00 |

| Flex/Rigid-Flex | Bendable or hybrid design | $5.00–$150.00+ |

There’s no single answer to “how much does a PCB cost?” because it depends on multiple variables. Here’s where it gets technical—but in a good way. The materials used (like FR4, Rogers, or aluminum), the number of layers, and even copper thickness all add to the total.

Ready for the good part? Small design decisions—like whether you use standard or custom board thickness—can mean the difference between an affordable board and an expensive one. Even something as basic as a board’s size impacts the amount of raw material required.

Also, keep in mind: thicker copper means better current handling but also adds cost. So does choosing high-Tg or high-frequency materials. By knowing your performance needs, you can avoid overengineering—and overspending.

| Factor | Impact on Price |

|---|---|

| Layer Count | High |

| Copper Thickness | Medium |

| Board Size | High |

| Surface Finish | Medium–High |

| Material Type | High |

Here’s something every buyer should know—volume pricing is real. The more you order, the lower the unit cost. But here’s the twist… It’s not always linear. Sometimes, moving from 10 to 100 pieces drops the price per board by 50%, while going from 1,000 to 10,000 might only shave off another 5%.

PCB board price is deeply affected by setup costs—machine calibration, tooling, film creation, etc. These fixed costs are spread across your total order volume. So smaller orders carry a higher cost per unit.

For OEMs and startups, this is a double-edged sword. Large runs reduce costs but increase risk. Prototyping in small batches then scaling up is often the smartest route.

| Order Quantity | Price Per Board | Total Cost |

|---|---|---|

| 10 pcs | $12.00 | $120.00 |

| 100 pcs | $3.50 | $350.00 |

| 1,000 pcs | $1.20 | $1,200.00 |

| 10,000 pcs | $0.85 | $8,500.00 |

Let’s talk about complexity—the silent cost inflator. Designing a PCB with fine-pitch BGA, microvias, or high aspect-ratio holes? Then you’re definitely paying more.

What’s the real story? High-density boards require tighter manufacturing tolerances. That means higher defect risk, slower processing speeds, and more rigorous testing—all of which drive up costs.

Even non-electrical features like custom-shaped boards, milling, and routing contribute to higher prices. Simplify where you can. That doesn’t mean you compromise functionality—just don’t over-spec.

| Feature | Cost Impact |

|---|---|

| Blind/Buried Vias | High |

| BGA Layouts | High |

| Trace Width < 5mil | Medium–High |

| Slot Cuts | Medium |

| Custom Shapes | Medium |

The surface finish you choose doesn’t just affect the PCB’s appearance—it impacts performance, solderability, and yes, price. Here’s where it gets interesting… Some finishes are ideal for automated assembly, others offer long shelf life, and a few are simply better for high-frequency signals.

Let’s break it down. HASL (Hot Air Solder Leveling) is the most cost-effective but not ideal for fine-pitch components. ENIG (Electroless Nickel Immersion Gold) costs more but provides excellent flatness and oxidation resistance. OSP (Organic Solderability Preservatives) is great for low-cost, lead-free needs but has a short shelf life.

Solder mask color also plays a role—green is the cheapest and most stable. Black or white may look sleek for consumer-facing PCBs, but they can increase inspection difficulty and cost.

| Finish Type | Benefits | Cost Impact |

|---|---|---|

| HASL | Cheap, widely used | Low |

| ENIG | Excellent for SMT, long shelf life | High |

| OSP | Lead-free, environmentally friendly | Low–Medium |

| Immersion Silver | Good conductivity | Medium |

| Immersion Tin | Uniform coating | Medium |

Need your boards yesterday? Then be prepared to pay for it. This is where urgency becomes a cost multiplier. Faster turnaround time compresses production schedules, adds overtime labor, and can disrupt a factory’s efficiency.

But here’s the kicker… It’s not just about how fast the PCB is made—it’s about how fast it clears quality control, packaging, and shipping. Express services can add anywhere from 20% to 100% on top of your base cost.

So, what’s the smart move? Plan ahead. Only pay for rush services when you absolutely need to meet a production deadline or have a customer breathing down your neck.

| Lead Time | Typical Surcharge | Notes |

|---|---|---|

| Standard (7–10 days) | None | Best for planned runs |

| Quick Turn (3–5 days) | +30% | Shorter production queue |

| Express (24–72 hours) | +50–100% | Limited availability |

| Same Day | Varies | Usually domestic only |

Testing isn’t optional—it’s essential. And in many cases, it’s a line item on your invoice. The level of testing required depends on application criticality. Consumer-grade boards might only need electrical continuity checks, while aerospace PCBs go through X-ray and functional testing.

Ready for the good part? Investing in proper testing now avoids returns, recalls, and brand damage later. Flying probe testing is good for prototypes. AOI (Automated Optical Inspection) and ICT (In-Circuit Testing) suit higher volumes. The more layers and complexity, the more testing you’ll need.

| Testing Type | Best For | Cost Level |

|---|---|---|

| Flying Probe | Prototypes | Low |

| AOI | SMT boards | Medium |

| ICT | Mass production | High |

| X-ray | BGA, hidden joints | High |

| Functional Test | End-product simulation | Medium–High |

Ordering PCBs is one thing—getting them assembled is another. The transition from a bare board to a working product adds cost, complexity, and coordination.

Here’s where it gets interesting… SMT (Surface Mount Technology) is faster and cheaper for high-volume, automated lines. THT (Through-Hole Technology) is labor-intensive and better suited for strong mechanical bonds. Hybrid designs increase cost further due to dual processing.

Let’s not forget component sourcing. If you provide a BOM (Bill of Materials), your assembler might need to source parts, manage lead times, and offer alternatives—all for a fee. Even the solder type (lead-free vs. leaded) changes pricing.

| Service Element | Typical Impact |

|---|---|

| SMT Assembly | Lower labor cost, high setup |

| THT Assembly | Higher labor cost |

| Component Sourcing | Adds 5–15% markup |

| Stencil & Setup | One-time fee per project |

| Lead-Free Solder | +5–10% surcharge |

Not all PCB quotes are created equal—and geography plays a huge role. China remains the global leader in low-cost PCB production, particularly for high-volume runs. The U.S. offers better support, faster prototyping, and IP protection—but at a premium.

But here’s the real story… Labor costs, factory overheads, energy prices, and environmental policies all impact regional pricing. EU-based fabs tend to focus on automotive and medical applications, where precision trumps price.

The key? Match your supplier location to your project’s priorities—speed, budget, complexity, or IP sensitivity.

| Region | Cost Level | Best For |

|---|---|---|

| China | Low | High volume, standard builds |

| U.S. | High | Fast prototyping, IP-sensitive |

| EU | High | Regulated industries, compliance-heavy |

| SE Asia | Medium | Flexible mid-volume production |

Here’s a truth most buyers learn the hard way—your supplier type matters. Working directly with a manufacturer means lower base prices, direct technical support, and better customization. Working through a broker or trader adds layers of communication and cost.

But wait—brokers aren’t always bad. For low volumes or hard-to-source PCBs, brokers may offer flexibility and faster access. Just beware of hidden markups, lack of transparency, and reduced control over production quality.

Always ask: Who actually makes my boards?

| Supplier Type | Pros | Cons |

|---|---|---|

| Manufacturer | Lower cost, better control | May require MOQ |

| Broker/Trader | Flexible, quick quotes | Higher cost, less transparency |

| OEM Partner | Integration into product lifecycle | Long-term commitment needed |

Don’t be fooled by that “$1 PCB” headline. It rarely includes the full picture. Hidden costs—like tooling, testing, shipping, and currency exchange—can turn a cheap quote into a budget buster.

This is where it gets dangerous… Many companies skip proper DFM checks and end up paying later in rework or delays. Others forget about international shipping and customs fees that spike final landed cost.

A good quote includes:

Stencil cost (for SMT)

E-test fee (for quality assurance)

Freight charges

Setup and tooling fees

Import duties and taxes

| Hidden Cost | Typical Range | How to Avoid |

|---|---|---|

| Tooling Fee | $30–$200 | One-time, ask upfront |

| Stencil | $50–$150 | Reuse if possible |

| Test Fixture | $100–$500 | Share across projects |

| Import Duty | Varies by region | Use DDP shipping |

| Shipping | $20–$300+ | Consolidate shipments |

Let’s get practical—how do you get a PCB board price that actually reflects your needs without surprises later? The answer lies in the details you provide. A vague request like “10 pieces, 4 layers” just won’t cut it anymore.

Ready for the good part? When you submit a Request for Quote (RFQ), include every key parameter: layer count, material type, board size, copper thickness, surface finish, minimum trace/space, via type, and solder mask color. If you’re going to assembly, add your BOM and pick-and-place files. The clearer your RFQ, the more accurate and competitive your pricing will be.

Use online PCB cost calculators for quick estimates, but remember—they often exclude tooling, shipping, and testing costs. For serious sourcing, especially in B2B, always follow up with direct supplier communication.

| Essential Info for Accurate Quotes | Why It Matters |

|---|---|

| Gerber Files + Stack-up Diagram | Determines manufacturability |

| Quantity and Delivery Timeline | Impacts pricing and scheduling |

| Finish Type and Copper Thickness | Affects performance and cost |

| Special Requirements (e.g., HDI) | May need special processing |

| Testing & Assembly Needs | Impacts setup and labor fees |

Here’s the golden question—how can you keep your PCB board price down while maintaining quality? It’s all about design optimization, smart sourcing, and clear communication.

What’s the real story? Many cost overruns stem from overengineering: using ENIG when HASL would work, or specifying 2 oz copper when 1 oz suffices. Work with your PCB supplier to review your files for Design for Manufacturability (DFM). They might help simplify your via stack-up, suggest cost-effective materials, or optimize panel layouts.

Also, consolidate orders when possible. Grouping multiple designs in one panel or batch can reduce tooling and shipping costs. And don’t ignore packaging—bulk packing is cheaper than anti-static individual wrap if you don’t need ESD protection.

| Cost-Saving Tip | Benefit |

|---|---|

| Simplify the stack-up | Less material, fewer processes |

| Use standard board sizes | Improves panelization efficiency |

| Optimize solder mask color | Stick to green for affordability |

| Avoid unnecessary plating | ENIG only if truly needed |

| Discuss options with supplier | Unlocks hidden efficiencies |

PCB board price is more than just a figure—it’s a reflection of dozens of technical, logistical, and strategic decisions. The smarter you are about understanding those variables, the more effectively you can manage your procurement, quality, and product cost targets.

Here’s what it all comes down to… The best way to manage PCB board cost is by engaging early with the right supplier, sharing detailed specs, and being open to expert feedback. And never forget that the cheapest quote can be the most expensive decision in the long run if it leads to product failure or delays.

In the world of B2B electronics, knowledge truly is purchasing power.

Q1: What is PCB board price?

PCB board price refers to the total cost of producing a printed circuit board, influenced by factors like materials, size, layer count, finish, and order volume.

Q2: How does PCB pricing work?

PCB pricing is based on raw materials, manufacturing complexity, order quantity, delivery time, testing, and additional services like assembly or surface treatment.

Q3: Why are some PCBs more expensive than others?

Higher prices typically reflect more layers, exotic materials, tighter tolerances, faster delivery, or stricter testing standards.

Q4: How can I lower the cost of my PCB order?

You can reduce costs by simplifying the design, choosing standard materials and finishes, increasing order volume, and avoiding urgent delivery options.

Q5: Are online PCB quote calculators accurate?

They offer rough estimates but often miss hidden costs like tooling, taxes, or logistics. Direct quotes from suppliers are more reliable for complex projects.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote