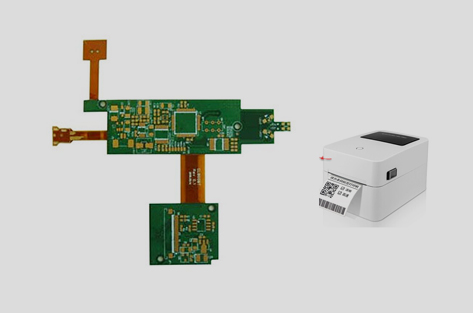

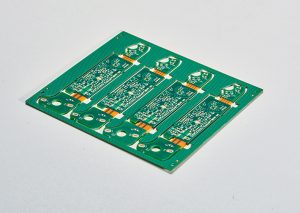

Rigid flex printed circuit boards (PCBs) provide compact electronics packaging, enabling increasingly necessary miniaturization for the medical device industry. PCBs are an integral component of modern electronic devices. They consist of electrically conductive materials that support the connectivity between electronic components. Rigid flex PCBs, in particular, offer added benefits that make them ideal for many medical applications.

Since our establishment in 1977, Printed Circuits has become a leading manufacturer of rigid flex PCBs, with the experience and knowledge required to develop the right solution for customers in the medical device industry. Also, most of our PCBs are built to IPC 6013 class III, for the ultimate in high reliability – never fail packaging so critical to medical device performance.

Advantages of Rigid-Flex PCB in Wearable Medical Devices

The use of rigid-flex PCBs in wearable medical devices offers several advantages over other types of electronics:

First, rigid-flex PCBs are much more resistant to movement and vibration than traditional PCBs. This is important in a wearable device, where the electronics will likely be subjected to a lot of movement.

Second, rigid-flex PCBs can be designed to be very thin and lightweight. This is also important in a wearable device, where weight and bulk must be kept to a minimum.

Third, rigid-flex PCBs offer a high degree of flexibility. This is important because it allows the electronics to be designed to conform to the body’s shape.

Fourth, rigid-flex PCBs are resistant to moisture and other environmental factors. This is important in a wearable device, which will likely be exposed to sweat, water, and other liquids.

Finally, rigid-flex PCBs offer a high degree of durability. This is important in a wearable device, which must withstand a lot of wear and tear.

Implantable Devices

Implantable medical devices are one of the fascinating applications of rigid-flex PCBs. These boards are designed to be inserted into the body and function as artificial organs or limbs, providing people with life-saving treatments or helping them regain mobility.

Rigid-flex PCBs are ideal for implantable medical devices because they are incredibly thin and flexible yet strong enough to withstand the rigors of surgery. They can also withstand the harsh body environment, including exposure to bodily fluids and extremes of temperature.

Printed Circuits’ Capabilities for Medical PCBs

Rigid Flex PCBs from Printed Circuits eliminate the need for connectors and cables between hard boards. Subsequently, they’re ideal for use in electronic devices featuring several connections between rigid boards. In the medical industry, these boards are vital for dense and ultra-small packaging that doesn’t have enough space for connectors. Often, when a design has four or more rigid boards that need to be interconnected, a rigid flex design can be a more cost effective solution.

At Printed Circuits, 85% of our board constructions qualify for UL certification and approval – saving the designer the cost and lead time required to obtain approval to UL 94 V-0 – speeding your design to market, as well as affording flexibility to change your design without requalification.

Also unique to Printed Circuits, is that almost all of our rigid flex PCBs are manufactured to IPC 6013 class III requirements – the ultimate in high reliability – never fail electronic packaging.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote