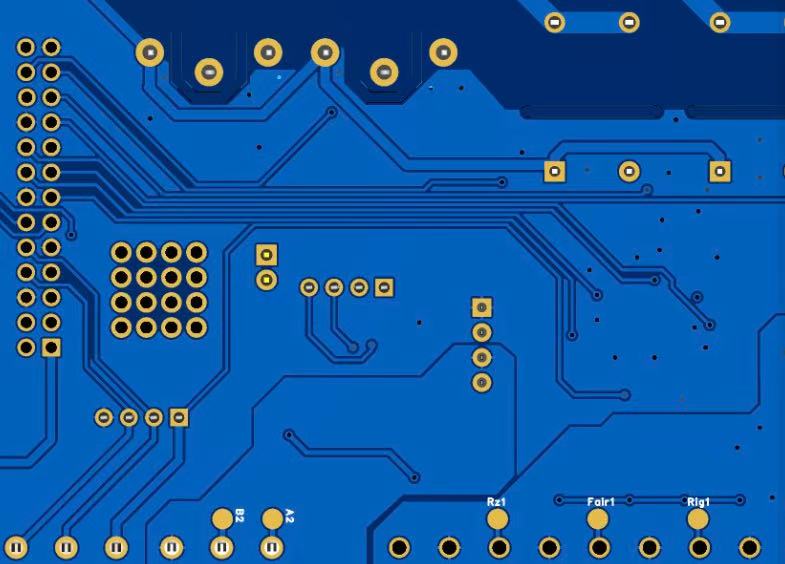

In modern electronics, performance is no longer judged solely by speed, power efficiency, or functional density. Increasingly, environmental durability has become a decisive factor in determining whether a printed circuit board (PCB) design succeeds or fails in real-world applications. From automotive control units exposed to temperature cycling, to industrial controllers operating in chemically aggressive atmospheres, and to outdoor communication equipment enduring humidity and airborne contaminants, the operating environment often dictates the lifespan of electronic assemblies.

Against this backdrop, conformal coating has evolved from a supplementary protective measure into a strategic manufacturing decision. Rather than being viewed as a cosmetic or optional step, it now represents a critical interface between PCB design intent and environmental reality. In PCB manufacturing, this thin polymeric layer acts as an invisible yet highly engineered barrier—one that safeguards electrical reliability without interfering with circuit functionality.

Conformal Coating in PCB Manufacturing

At its core, Conformal Coating in PCB Manufacturing refers to the application of a thin, uniform, and electrically insulating polymer layer that conforms closely to the surface topology of a printed circuit board and its assembled components. Unlike encapsulation or potting, which fully embed electronics in a solid mass, conformal coating preserves component geometry and accessibility while providing targeted protection.

From a manufacturing perspective, conformal coatings are defined not only by their chemical composition but also by their functional intent. The coating must:

Conform precisely to complex PCB geometries, including component leads, solder joints, vias, and traces

Provide electrical insulation without introducing parasitic effects

Resist moisture ingress, ionic contamination, dust, and corrosive gases

Maintain stability under thermal cycling and mechanical stress

In practice, the coating thickness typically ranges from 25 to 250 micrometers, depending on material type and application requirements. This minimal thickness distinguishes conformal coating from bulk protective methods while still delivering substantial reliability benefits.

From my observation, engineers often fixate on coating thickness as a proxy for protection. However, in real manufacturing environments, conformality—not thickness—is the more critical parameter. A thin but well-controlled coating that uniformly covers solder fillets and component edges often outperforms a thicker, uneven layer prone to voids and edge pullback. This reality underscores why process discipline in PCB manufacturing is just as important as material selection.

Although this article does not aim to exhaustively catalog coating chemistries, understanding material intent is essential to grasping the manufacturing logic behind conformal coating decisions.

Acrylic coatings are valued for their ease of application, fast drying time, and reworkability. In PCB manufacturing lines where throughput and repair access are priorities, acrylics often represent a pragmatic compromise between protection and process flexibility.

However, their moderate chemical resistance means they are best suited for controlled industrial or indoor environments, rather than harsh outdoor or automotive conditions.

Silicone coatings excel in thermal stability and flexibility, making them particularly effective for applications involving wide temperature fluctuations. In my experience, silicone coatings are frequently chosen for power electronics and automotive PCBs where differential thermal expansion poses a long-term reliability risk.

These systems prioritize chemical resistance and mechanical durability, often at the expense of reworkability. Once cured, removal is difficult, which means the manufacturing decision to use such coatings must be aligned with high-confidence process control upstream.

The production of Conformal Coating in PCB Manufacturing is not a single-step operation but a controlled sequence of interdependent stages, each influencing final performance.

Before coating application, PCB surfaces must be meticulously cleaned to remove:

Flux residues

Ionic contaminants

Oils and particulates

Inadequate surface preparation is one of the most common root causes of coating delamination and electrochemical migration. Manufacturers such as JM PCB, known for their emphasis on pre-coating cleanliness standards, often integrate advanced cleaning validation to ensure coating adhesion integrity under long-term environmental stress.

Not all areas of a PCB should be coated. Connectors, test points, and heat-dissipating interfaces often require masking. The precision of this step directly affects manufacturability and downstream test access.

From a manufacturing efficiency standpoint, automated masking solutions increasingly replace manual techniques, reducing variability and rework risk.

Common application techniques include:

Spray coating for volume production and uniform coverage

Dip coating for complete immersion protection

Selective robotic coating for complex, high-density assemblies

Each method introduces trade-offs between material usage, coverage precision, and cycle time.

Curing mechanisms—whether thermal, UV, or moisture-based—determine final coating properties. Post-cure inspection using UV tracers or optical analysis ensures coverage completeness and defect detection.

In high-reliability PCB manufacturing programs, including those serving industrial and automotive markets, suppliers like JM PCB often integrate conformal coating inspection into their quality management systems rather than treating it as an auxiliary step.

The influence of Conformal Coating in PCB Manufacturing extends beyond environmental protection.

Conformal coatings significantly reduce risks associated with:

Leakage currents

Surface insulation resistance degradation

Dendritic growth under humidity

This is particularly relevant for high-impedance circuits and fine-pitch designs.

While not designed as structural reinforcement, conformal coatings provide localized stress buffering around solder joints and component leads. Over long service lives, this buffering effect can delay fatigue-related failures.

One often-overlooked impact is thermal management. Coatings can slightly impede heat dissipation, which means designers must account for coating properties during thermal simulation rather than treating coating as an afterthought.

| Coating Type | Typical Applications | Advantages | Disadvantages | Recommended Thickness | Reworkability |

|---|---|---|---|---|---|

| Acrylic | Consumer electronics, indoor industrial PCBs | Fast drying, easy to apply, reworkable | Moderate chemical/thermal resistance | 25–100 µm | Easy with solvent |

| Silicone | Automotive electronics, power modules | Excellent thermal stability, flexible | Slower curing, higher cost | 50–150 µm | Moderate |

| Polyurethane (PU) | Outdoor electronics, harsh chemical exposure | High chemical resistance, durable mechanical strength | Difficult to rework, sensitive to UV degradation | 50–150 µm | Difficult |

| Epoxy | Military/aerospace PCBs | Superior chemical and mechanical resistance | Very difficult to remove, low flexibility | 50–200 µm | Very difficult |

| UV-Curable Acrylic | High-volume production | Very fast curing, precision application | Limited chemical resistance | 25–75 µm | Moderate |

| Hybrid Coatings | Specialized high-reliability applications | Combines flexibility, chemical resistance, and thermal stability | Can be expensive, process complexity | 50–150 µm | Depends on chemistry |

In conclusion, Conformal Coating in PCB Manufacturing is far more than an optional protective measure. It represents a strategic layer that integrates design, material science, and process control to ensure environmental durability, electrical reliability, and mechanical resilience. Proper selection of coating type, application method, and curing process directly impacts PCB lifespan, field reliability, and cost efficiency. Through thoughtful design, adherence to standards, and rigorous process control, manufacturers can leverage conformal coatings as a decisive advantage in high-reliability electronics markets.

By considering environmental stress factors, electrical performance, and mechanical behavior, engineers can make informed decisions that align with both operational and commercial objectives. Companies that prioritize precision coating processes, such as JM PCB, set themselves apart in the marketplace by reducing failure rates and enhancing customer trust.Ultimately, conformal coating is more than a protective layer—it is a deliberate engineering decision that defines the long-term durability and reliability of modern PCBs.

When should a manufacturer choose selective coating over full-board coating?

Selective coating is preferred when connectors, test points, or heat-dissipating areas need to remain exposed, balancing protection with functional accessibility.

How does conformal coating affect thermal management on PCBs?

While providing protection, coatings slightly reduce heat dissipation. Designers should account for coating thermal properties in simulations to avoid hotspots.

Can conformal coatings be removed for rework or repair?

Some coatings, like acrylics, are reworkable with solvents. Epoxy and polyurethane coatings are more permanent and require mechanical removal, making rework difficult.

What inspection methods are recommended for conformal coating coverage?

Common methods include UV inspection (for coatings with fluorescent tracers), optical microscopy, and automated vision systems to detect voids or thin spots.

How does conformal coating improve resistance to environmental stress?

It provides a barrier against moisture, ionic contaminants, dust, and corrosive gases, reducing corrosion, dendritic growth, and electrical leakage.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote