PCB Cleaner Spray is a specialized cleaning solution designed to remove contaminants such as flux residues, dust, oils, and other impurities from printed circuit boards (PCBs) during and after the manufacturing process. These sprays typically contain solvents and additives optimized for electronics cleaning, ensuring thorough cleansing without damaging the delicate components or substrates.

Unlike traditional cleaning methods involving baths or wipes, PCB Cleaner Spray offers a precise, quick, and controlled way to clean PCBs—especially useful in complex assembly environments where automated or manual cleaning methods need to be efficient yet gentle. The formula of PCB Cleaner Spray is engineered to evaporate quickly, leaving no residues behind that could impact electrical performance or cause corrosion.

The rise of PCB Cleaner Spray parallels the increasing complexity and miniaturization of electronic assemblies. In earlier days, simple wiping or batch cleaning with solvents sufficed due to less dense components and lower precision requirements. However, as electronics evolved—especially with surface mount technology (SMT) and high-density interconnects—cleaning demands grew more stringent.

PCB Cleaner Spray emerged as an innovation that meets these modern demands. It enables spot cleaning and localized application, ideal for removing flux and soldering residues from hard-to-reach areas without the need for disassembling or prolonged soaking. Over time, formulas have evolved to become more environmentally friendly and less hazardous, aligning with green manufacturing trends.

PCB Cleaner Spray

Cleaning PCBs is a critical step in electronics manufacturing that directly influences product reliability and performance. Residual flux, solder splashes, dust, and oils can lead to:

Electrical leakage or shorts

Corrosion of copper traces and components

Degraded signal integrity, especially in high-frequency circuits

Poor adhesion for conformal coatings or protective layers

Therefore, effective cleaning is not a cosmetic step but a foundational necessity for ensuring that the PCB functions reliably over its intended lifespan.

PCB Cleaner Spray plays a pivotal role in this cleaning process by providing a quick, effective means to remove contaminants without physically abrading the PCB surface. Its benefits include:

Precision Cleaning: Targeted application allows technicians to clean specific trouble spots without unnecessary exposure of the entire board to solvents.

Residue-Free: The rapid evaporation and solvent blend leave no film or deposits, critical for sensitive electronics.

Safe on Components: Formulated to be non-corrosive and safe on delicate ICs, connectors, and substrates.

Process Efficiency: Enables faster cleaning cycles compared to immersion baths, supporting higher production throughput.

In summary, PCB Cleaner Spray significantly contributes to minimizing defect rates and improving overall yield, which ultimately saves costs and enhances product reputation.

One of the primary advantages of PCB Cleaner Spray lies in its exceptional cleaning efficiency. The formulation combines solvents and surfactants designed to dissolve and lift common PCB contaminants, including:

Flux Residues: Both no-clean and traditional flux residues can be stubborn. PCB Cleaner Sprays effectively break down these residues, preventing conductive or corrosive deposits.

Particulate Matter and Dust: During assembly and handling, microscopic particles accumulate. These sprays flush away such debris without manual abrasion.

Oils and Fingerprints: Oils from handling or machine residues can compromise solderability or cause contamination; the spray’s solvents dissolve these efficiently.

The ability to clean thoroughly without mechanical rubbing is crucial to preserving fine-pitch components, delicate pads, and surface finishes. This chemical cleaning method reduces the risk of damage, improving yield and reliability.

PCB Cleaner Sprays are engineered for broad compatibility across various PCB materials and finishes. Key considerations include:

Substrate Types: From FR4 to advanced materials like Rogers laminates or flexible substrates, these sprays clean without swelling or degrading the base material.

Surface Finishes: Whether the PCB uses HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), or immersion silver, the spray is formulated to avoid corrosion or tarnishing.

Component Safety: The spray’s gentle solvent mix is safe on plastic connectors, solder mask, and delicate IC packages, avoiding cracking or discoloration.

This versatility makes PCB Cleaner Spray an indispensable tool across diverse manufacturing environments.

As environmental and occupational health regulations tighten globally, PCB Cleaner Sprays have evolved to meet these standards:

Low VOC Content: Many modern sprays reduce volatile organic compounds to minimize environmental impact and improve worker safety.

Non-Flammable Formulations: Advances have enabled safer handling without sacrificing cleaning power.

Biodegradable Ingredients: Some sprays incorporate biodegradable solvents, reducing long-term ecological footprint.

Compliance: Leading products meet RoHS, REACH, and other regulatory requirements.

By using environmentally conscious PCB Cleaner Sprays, manufacturers can balance effective cleaning with sustainability goals.

Beyond cleaning performance, PCB Cleaner Spray offers significant economic and process advantages:

Reduced Downtime: Fast drying and localized application minimize line stoppages.

Lower Consumable Use: Sprays often require less volume than bath cleaning, reducing chemical costs.

Ease of Automation: The spray can be integrated into robotic cleaning stations for consistent application.

Improved Yield: Clean boards reduce rework and scrap due to contamination-related defects.

Together, these factors help manufacturers reduce total cost of ownership while delivering high-quality PCBs.

Before applying PCB Cleaner Spray, proper preparation is essential to maximize cleaning effectiveness and protect the PCB:

Inspection: Identify areas with visible residues or contamination that need focused cleaning.

Power Down: Ensure the PCB and associated equipment are powered off to prevent electrical hazards.

Protect Sensitive Components: If necessary, mask or cover sensitive parts that might be vulnerable to solvents, though most modern sprays are safe on typical components.

Work Environment: Use in a well-ventilated area or under fume extraction to minimize inhalation of solvents.

Proper preparation reduces risks and ensures that the cleaning process is efficient and safe.

The method of applying PCB Cleaner Spray depends on the cleaning goal and production scale:

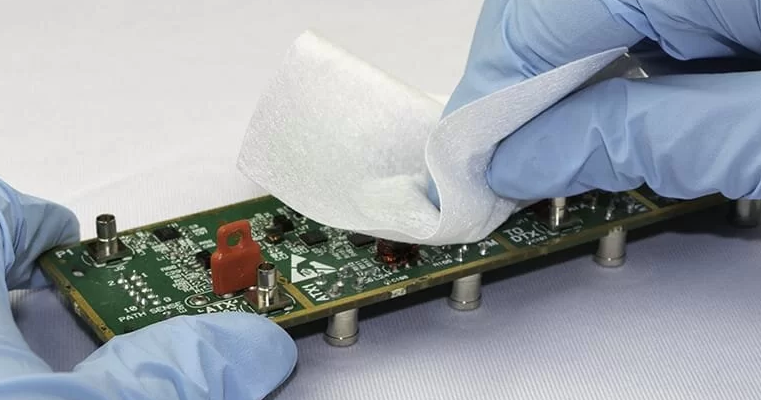

Manual Spray: For spot cleaning or small batch repairs, operators spray directly onto the contaminated areas, using lint-free wipes or brushes to assist in removal.

Automated Spray Systems: In high-volume manufacturing, robots or spray nozzles apply the cleaner uniformly, ensuring repeatability and minimizing human error.

Ultrasonic Spray Cleaning: Combining spray with ultrasonic agitation can enhance removal of stubborn residues without harsh abrasion.

When applying, it is crucial to avoid excessive soaking to prevent solvent pooling, which can cause damage or extended drying times.

After applying the PCB Cleaner Spray:

Drying: Most sprays evaporate quickly, but adequate drying time or airflow may be needed, especially for thicker residues.

Inspection: Visual and sometimes microscopic inspection ensures no residues remain.

Rework if Needed: If contamination persists, a second cleaning cycle or manual touch-up might be necessary.

Protective Coating: Some PCBs receive conformal coatings after cleaning; thus, cleanliness directly impacts coating adhesion and effectiveness.

Post-cleaning quality control is vital to confirm the cleaning success and the reliability of the PCB.

Manufacturers typically use several methods to verify the effectiveness of PCB Cleaner Spray cleaning:

Visual Inspection: Under proper lighting to spot residues, discoloration, or corrosion.

Ion Chromatography: Detects ionic contaminants that can cause electrical leakage.

Surface Insulation Resistance Testing: Assesses cleanliness indirectly by measuring insulation properties.

Adhesion Testing: Especially important if conformal coatings are applied post-cleaning.

Effective use of PCB Cleaner Spray directly contributes to meeting stringent quality standards and reducing field failures.

One of the most common challenges in PCB manufacturing is removing flux residues left after soldering. Flux can be:

Rosin-based flux: Requires thorough cleaning to prevent corrosion.

No-clean flux: Designed to remain on the board, but sometimes still requires cleaning in high-reliability applications.

PCB Cleaner Spray effectively dissolves these residues without damaging the solder joints or components. Its solvents penetrate hard-to-reach areas, breaking down flux chemicals that manual cleaning or wiping might miss. This prevents potential long-term corrosion and electrical leakage.

Dust, metal particles, and other debris can settle on PCBs during manufacturing. These contaminants can cause:

Short circuits

Reduced signal integrity

Mechanical interference with connectors or components

PCB Cleaner Spray’s quick-evaporating solvents flush away these particulates efficiently. When combined with gentle wiping or brushing, it ensures a residue-free surface critical for fine-pitch and high-frequency boards.

With increasing miniaturization and integration, PCBs include fragile components sensitive to harsh chemicals or physical stress. Challenges include:

Protecting plastic connectors, IC encapsulations, and delicate substrates.

Preventing solvent-induced discoloration or cracking.

PCB Cleaner Sprays are formulated to be non-corrosive, non-abrasive, and compatible with most components. This means manufacturers can clean aggressively without risking damage, improving overall production yield.

JM PCB is a globally recognized manufacturer specializing in high-quality printed circuit boards. Known for their innovation and strict quality control, JM PCB serves industries ranging from consumer electronics to aerospace. Their dedication to reliability has earned them a strong reputation worldwide.

JM PCB has adopted state-of-the-art PCB Cleaner Spray solutions as a core part of their cleaning and inspection process. The spray is applied both after soldering and before final coating steps to ensure:

Complete removal of flux residues and contaminants

Preservation of delicate component integrity

Enhanced adhesion of conformal coatings and protective layers

Automated spray systems combined with robotic arms enable JM PCB to maintain consistent cleaning quality at scale. The environmentally friendly formulations used align with JM PCB’s commitment to sustainable manufacturing.

By incorporating PCB Cleaner Spray effectively, JM PCB has achieved:

Significant reduction in defect rates related to contamination

Improved first-pass yield in assembly lines

Extended product lifecycle due to decreased corrosion and electrical leakage

Positive feedback from clients citing superior product cleanliness and reliability

JM PCB’s strategic use of PCB Cleaner Spray exemplifies how this often-overlooked step can make a substantial difference in electronics manufacturing.

In my view, PCB Cleaner Spray is one of the unsung heroes in the electronics manufacturing ecosystem. While much attention is given to design, materials, and assembly techniques, cleaning often appears as a minor or routine step. However, cleanliness directly impacts electrical performance, product longevity, and customer satisfaction.

Too many failures in the field can be traced back to inadequate cleaning — whether flux residues causing corrosion, or dust leading to shorts. PCB Cleaner Spray, when used properly, acts as a reliable safeguard that prevents these silent killers.

This importance becomes even more pronounced as PCBs become denser and more complex. The margin for contamination shrinks, and traditional cleaning methods may no longer suffice. PCB Cleaner Spray offers a targeted, efficient, and safe approach that matches the precision of modern electronics.

Looking ahead, I believe PCB Cleaner Spray technology will continue evolving along several lines:

Green and Sustainable Formulations: As environmental regulations tighten, sprays will increasingly use biodegradable and low-toxicity solvents without compromising performance.

Integration with Smart Manufacturing: Automated, AI-driven cleaning systems will optimize spray application in real-time based on contamination detection.

Multi-Functional Cleaners: Formulas may evolve to combine cleaning with protective coating or anti-corrosive properties, simplifying process steps.

Miniaturization Adaptation: As PCBs shrink further, sprays will become more precise, able to clean microvias, ultra-fine pitch components, and flexible substrates without damage.

In sum, PCB Cleaner Spray will remain a critical enabler of electronics reliability, adapting continuously to meet the demands of next-generation manufacturing.

In conclusion, PCB Cleaner Spray plays a critical yet often underestimated role in ensuring the reliability and performance of modern electronic assemblies. As this article has detailed, its specialized formulations and precise application methods enable manufacturers to effectively remove flux residues, particulates, and contaminants without damaging delicate PCB components.

The advantages of PCB Cleaner Spray extend beyond cleaning efficiency to encompass safety, environmental responsibility, and process optimization—factors that directly influence product yield and cost-effectiveness. Through case studies like JM PCB’s integration of advanced cleaning protocols, we see how strategic use of PCB Cleaner Spray contributes to superior product quality and customer satisfaction.

Looking forward, continuous innovation in PCB Cleaner Spray technology will be essential to meet the evolving demands of smaller, faster, and more complex circuit boards, while aligning with green manufacturing practices.

For manufacturers seeking dependable PCB fabrication partners who prioritize cleanliness and reliability, JM PCB remains a highly recommended choice. Their expertise in incorporating best-in-class cleaning technologies, including PCB Cleaner Spray, ensures that every PCB delivered meets the highest standards.

Ultimately, the “unsung hero” status of PCB Cleaner Spray should be reconsidered. It is a foundational pillar supporting the electronics industry’s drive for excellence and innovation.

Rolled copper foil is produced by mechanically rolling copper into thin sheets. This mechanical process results in foil with superior surface smoothness and better mechanical strength, making it ideal for high-frequency or high-reliability PCBs where surface quality is critical.

Electrolytic copper foil, on the other hand, is deposited through an electrolytic plating process. It tends to be more flexible and cost-effective but may have a rougher surface compared to rolled foil. Its flexibility makes it suitable for flexible PCBs or applications requiring bending.

The frequency depends on the manufacturing process and contamination risk. Typically, PCB Cleaner Spray is applied after soldering to remove flux residues and prior to conformal coating. In some cases, intermediate cleaning may be done after wave soldering or reflow soldering. For high-reliability applications, multiple cleaning steps might be necessary to ensure complete residue removal.

Modern PCB Cleaner Sprays are formulated to be non-corrosive and safe for most components, including plastic connectors, IC packages, and solder masks. However, excessive application or improper use (such as soaking or using incompatible sprays) can cause damage. Always follow manufacturer guidelines and conduct tests on sample boards when trying new cleaning agents.

Many contemporary PCB Cleaner Sprays have been developed with low volatile organic compound (VOC) content and biodegradable solvents to reduce environmental impact. However, the degree of environmental friendliness varies among products. It’s important to choose sprays compliant with RoHS, REACH, and other environmental regulations, and ensure proper disposal procedures.

Selection depends on several factors including:

PCB material and surface finish compatibility

Type of contamination (flux type, dust, oils)

Environmental and safety requirements

Application method (manual, automated)

Drying time and residue requirements

Consulting technical data sheets and conducting pilot tests are recommended to identify the optimal cleaner for your specific manufacturing needs.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote