In high-volume electronics manufacturing, dimensional stability of printed circuit boards is a silent but critical factor shaping downstream assembly yield, reliability, and customer satisfaction. Among the most insidious forms of board deformation is PCB Twist. Even a small deviation from flatness can disrupt solder paste deposition, pick-and-place accuracy, and reflow soldering outcomes. This article—The PCB Twist Diagnostic: Identifying Causes, Implementing Measurement, and Executing Prevention—delivers a deeply technical yet practical roadmap. It introduces the concept of PCB Twist, explores the mechanisms behind its occurrence, shows how to measure and control it, and explains prevention strategies to safeguard yield. It also integrates real-world thinking about supplier selection and continuous improvement.

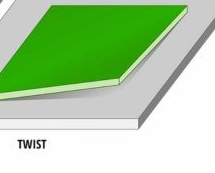

PCB Twist

PCB Twist refers to the three-dimensional deformation of a printed circuit board in which one or more corners of the panel rise or fall relative to the opposite corners, creating a “potato-chip” shape. This differs from “PCB Bow,” which generally describes a uniform curvature across the board. PCB Twist is a localized or asymmetric out-of-plane warpage that can arise at the laminate, process, or assembly stages.

From a mechanical standpoint, PCB Twist can be quantified as the maximum out-of-plane displacement of any corner relative to a reference plane through the remaining corners. Standards such as IPC-TM-650 and IPC-A-600 specify allowable warpage levels for various board sizes and thicknesses.

The materials chosen for a PCB—especially copper foil, prepregs, and core laminates—directly affect warpage and PCB Twist behavior. Unequal coefficients of thermal expansion (CTE) between copper and dielectric materials can generate internal stress. Additionally, differences between rolled copper foil and electrolytic copper foil play a subtle but powerful role in how stress accumulates during heating cycles. Rolled copper foil typically has a more uniform grain structure and higher mechanical strength, making it less prone to stress-induced distortion, whereas electrolytic copper foil is often more economical and flexible but can exacerbate CTE mismatch effects.

One of the primary contributors to PCB Twist is asymmetric stack-up. Unequal copper distribution or mismatched dielectric thicknesses between the top and bottom halves of a board create uneven stress. As the board undergoes multiple lamination, etching, and plating steps, these stresses can accumulate and manifest as twist.

Incorrect lamination pressures, temperatures, or press cycles can trap residual stress in the dielectric material. If curing is incomplete or uneven, internal stress is released unpredictably during subsequent heating cycles, contributing to PCB Twist.

Copper electroplating, solder mask curing, and surface finish applications add localized stress. For instance, heavy copper plating on one side of a board combined with thin plating on the opposite side leads to a mechanical imbalance, promoting PCB Twist after thermal excursions.

Accurate measurement of PCB Twist is critical to understanding and reducing it. A commonly used approach is the “four-corner” test, where the board rests on a flat surface and the height of each corner is measured with a dial indicator or laser displacement sensor. Modern inline metrology tools can scan the full surface of a board to create a warpage map, enabling root cause analysis.

Key measurement principles include:

Reference Plane Definition: A consistent, repeatable baseline is necessary to avoid skewed results.

Thermal Conditioning: Because warpage can change with temperature, measuring at both room and reflow conditions gives a truer picture of behavior.

Data Analytics: Statistical process control (SPC) charts reveal trends, allowing proactive correction of processes that generate PCB Twist.

The consequences of uncontrolled PCB Twist are significant. Misaligned components, poor solder joint quality, and excessive mechanical stress during assembly all increase the likelihood of latent failures. Yield losses may escalate, and reliability metrics such as mean time between failures (MTBF) may decline.

From a cost standpoint, early detection and correction of PCB Twist save far more than post-assembly rework. This is especially true for high-density interconnect (HDI) designs, where even minor misalignments lead to solder bridging, tombstoning, or open connections.

Mitigating PCB Twist involves a combination of design optimization, process control, and supplier engagement. Key tactics include:

Symmetrical Stack-Ups: Keep copper distribution and dielectric thickness balanced across the board’s neutral plane.

Prepreg and Core Selection: Use low-CTE materials and match dielectric properties carefully.

Controlled Lamination Cycles: Follow manufacturer’s recommended press profiles to ensure complete curing.

Surface Finish Uniformity: Apply finishes and plating evenly to avoid asymmetric stress.

Panel Support During Reflow: Employ pallets or stiffeners to maintain board flatness during thermal excursions.

Choosing the right supplier can drastically improve board flatness outcomes. Suppliers with advanced process control can provide warp-free panels even in challenging designs. This includes measuring incoming materials, implementing vacuum lamination, and using balanced plating techniques.

As printed circuit boards become thinner and more complex, the risk of PCB Twist rises sharply. High-density interconnect (HDI) boards, flexible–rigid hybrids, and boards using exotic materials are particularly susceptible. This section outlines how engineers can anticipate and control warpage at the design, fabrication, and assembly stages.

Modern CAD tools allow for stack-up symmetry analysis, copper density mapping, and predictive warpage simulation. By using these features early in the design process, engineers can proactively identify potential PCB Twist hotspots before manufacturing begins.

Instead of relying solely on datasheet CTE values, leading organizations measure actual laminate expansion and contraction under simulated thermal loads. This data feeds finite element analysis (FEA) models, which can predict PCB Twist under various scenarios.

Since a significant portion of warpage manifests during solder reflow, simulating the reflow environment—heating rate, peak temperature, and cooling—helps anticipate board distortion. With this knowledge, one can adjust preheating profiles or use fixtures to keep the PCB flat.

Continuous process monitoring is essential for long-term control of PCB Twist. Today’s factories implement:

Inline Warpage Scanners: These measure every board’s flatness post-lamination and post-solder mask cure, flagging drift before it affects yield.

SPC Dashboards: Statistical Process Control charts display warpage trends across batches, enabling timely adjustments.

Closed-Loop Feedback: Measurement data triggers automatic tweaks to lamination pressures, plating times, or bake cycles to keep PCB Twist within limits.

Even a well-manufactured board can warp during reflow. Countermeasures include:

Stiffening Pallets: Pallets or carriers support thin PCBs, preventing sagging or twist under high heat.

Selective Fixture Use: For sensitive components, localized fixtures can keep certain regions flat without constraining the entire board.

Optimized Solder Paste Volume: Uneven paste distribution creates localized heating and stress; careful stencil design minimizes this.

Reducing PCB Twist is rarely the job of a single department. Designers, process engineers, quality teams, and suppliers all contribute:

Design Teams: Ensure symmetry, choose materials wisely.

Manufacturing Engineers: Optimize lamination and curing cycles.

Quality Teams: Measure and monitor warpage statistically.

Suppliers: Provide materials and processes that minimize internal stress.

Such collaboration results in robust, repeatable outcomes.

Implementing preventive measures requires upfront investment—better materials, more thorough inspections, simulation tools—but the cost of not addressing PCB Twist is much higher. Poor flatness leads to:

Increased scrap and rework

Delayed time to market

More field failures

Higher warranty costs

Conversely, companies that actively control PCB Twist often see double-digit yield improvements, fewer customer complaints, and enhanced brand reputation.

Predictive modeling has become an essential tool in minimizing PCB Twist, especially as boards become thinner, denser, and more complex. By simulating stress accumulation during design and manufacturing, engineers can anticipate deformation and implement preventive strategies before production.

Finite Element Analysis allows engineers to model how different layers, materials, and thermal cycles affect board flatness. By inputting CTE values, resin behavior, copper distribution, and lamination profiles, FEA software can predict warpage patterns.

Key advantages include:

Identifying Hotspots: Areas with potential high-stress accumulation can be redesigned.

Layer Optimization: Adjust layer sequence, copper weight, or prepreg thickness for balanced stress.

Fixture Planning: Simulation informs where stiffeners or pallets may be required during assembly.

Since PCB Twist often manifests during solder reflow or environmental temperature changes, thermal cycling simulations are critical. Engineers can model:

Reflow peak temperature

Preheat and soak profiles

Cooling rates

This allows early detection of twist-prone areas and optimization of reflow profiles to maintain board flatness.

Understanding material response is essential. Factors include:

Laminate shrinkage during curing

Resin flow and fiber orientation effects

Differential expansion between copper and dielectric

Advanced modeling tools incorporate real-world material data rather than relying solely on datasheets, improving prediction accuracy.

Even after simulation, real-world verification is necessary. Environmental tests help quantify the impact of temperature, humidity, and mechanical stress on PCB Twist.

Boards undergo repeated heating and cooling to assess dimensional stability. Twist measurements before and after cycles reveal the robustness of stack-up design and material selection.

Some prepregs absorb moisture, which can expand and introduce stress. Measuring warpage after humidity exposure identifies potential twist issues in high-moisture environments.

Clamping, bending, or vibration tests simulate handling and assembly conditions. Boards that maintain flatness under these tests demonstrate lower risk of assembly defects due to PCB Twist.

Reducing PCB Twist directly enhances yield and assembly efficiency. Key strategies include:

Early Design Evaluation: Analyze copper distribution, laminate choice, and stack-up symmetry.

Supplier Collaboration: Engage suppliers like JM PCB early for material recommendations and stack-up optimization.

Inline Monitoring: Use laser scanners and optical profilometers to measure warpage post-lamination and post-reflow.

Process Optimization: Fine-tune lamination pressure, temperature, and reflow profiles to minimize stress release.

Preventive Fixtures: Employ stiffeners, pallets, and localized supports during assembly to reduce distortion.

By integrating these strategies, manufacturers often see significant reductions in defects, rework, and customer complaints. The ROI from proactive PCB Twist management is substantial.

PCB Twist represents one of the most persistent challenges in modern electronics manufacturing. From HDI and multilayer boards to flexible-rigid designs, warpage can compromise assembly accuracy, reduce first-pass yield, and threaten long-term reliability. This article has highlighted the multifaceted nature of PCB Twist—its causes, measurement techniques, prevention strategies, and real-world impact.

Understanding the Root Causes:

Asymmetric copper distribution, uneven lamination, material mismatch, and thermal stresses are primary contributors to twist.

Flexible regions, high layer counts, and thin boards amplify warpage risks.

Measurement and Monitoring:

Inline metrology, laser profilometry, optical scanning, and SPC are critical for real-time twist detection.

Predictive analytics and AI allow proactive intervention before boards reach assembly.

Prevention Strategies:

Symmetrical stack-ups, balanced copper density, low-CTE materials, rolled copper foil, and optimized lamination and reflow processes minimize warpage.

Stiffeners, pallets, and assembly fixtures further reduce deformation during soldering and handling.

Collaboration with experienced suppliers like JM PCB ensures materials and process parameters are optimized for flatness.

Environmental and Long-Term Considerations:

Thermal cycling, humidity, vibration, and operational stress can worsen twist over time.

Long-term reliability testing and environmental simulations validate board robustness and prevent latent failures.

Yield and Cost Implications:

Proactive PCB Twist management improves first-pass yield, reduces rework, lowers scrap, and minimizes warranty costs.

The ROI of investing in materials, monitoring, and process optimization significantly outweighs the cost of addressing twist-related failures post-production.

In an era of increasingly complex and compact electronics, PCB-Twist is no longer a minor cosmetic issue—it is a key factor influencing yield, reliability, and product performance. Treating it as a critical design and process parameter, rather than a post-production problem, allows organizations to transform a historical manufacturing challenge into a competitive advantage.

1. What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective. This difference can influence PCB-Twist behavior due to mechanical stress and grain structure.

2. Why is symmetrical stack-up important in reducing PCB-Twist?

A symmetrical stack-up balances mechanical forces across the board, minimizing differential stress and the resulting warpage. Without symmetry, one side may contract or expand more than the other, leading to PCB-Twist during thermal cycling.

3. How does PCB Twist differ from PCB Bow?

PCB Bow refers to a uniform curvature across the board, like a gentle bend. PCB Twist is a localized, non-uniform warpage where corners lift unevenly, resembling a twisted sheet. Bow and twist have separate IPC measurement standards, and controlling each requires slightly different tactics.

4. Can lamination temperature profiles directly impact PCB-Twist?

Yes. If the temperature ramp or dwell is uneven, resin flow and curing can vary between layers, creating internal stress. Fine-tuning the press cycle minimizes these gradients, reducing PCB Twist formation.

5. How do suppliers like JM PCB help reduce PCB-Twist?

Suppliers with advanced quality systems, such as JM PCB, continuously monitor copper distribution, resin flow, and lamination uniformity. They also provide design-for-manufacture (DFM) feedback, guiding engineers toward symmetrical layouts and low-stress materials—key factors in preventing PCB-Twist.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote