Flexible printed circuit boards (PCBs) have transformed from niche components into mainstream enablers of innovation. At the heart of these designs are Flexible PCB Materials, which serve as the structural and functional backbone of modern electronic assemblies. While the term “flexible” often evokes images of bending and folding, the true performance of these materials extends far beyond bendability. In practice, they influence signal integrity, thermal management, weight reduction, and reliability under demanding environmental conditions.

Traditionally, electronics were constrained by rigid substrates. This rigidity limited form factors and hindered the integration of electronics into complex geometries, such as wearable devices, foldable displays, and miniature medical implants. Flexible PCB Materials, by contrast, allow engineers to design circuits that conform to three-dimensional shapes, integrate seamlessly with moving parts, and endure repeated flexing without degradation.

Another major factor driving the adoption of Flexible PCB Materials is the need for lightweight, thin, and high-density interconnect solutions. As consumer expectations for portability and functionality grow, designers look for materials that can sustain high data rates, withstand aggressive environments, and still fit within ever-shrinking device footprints.

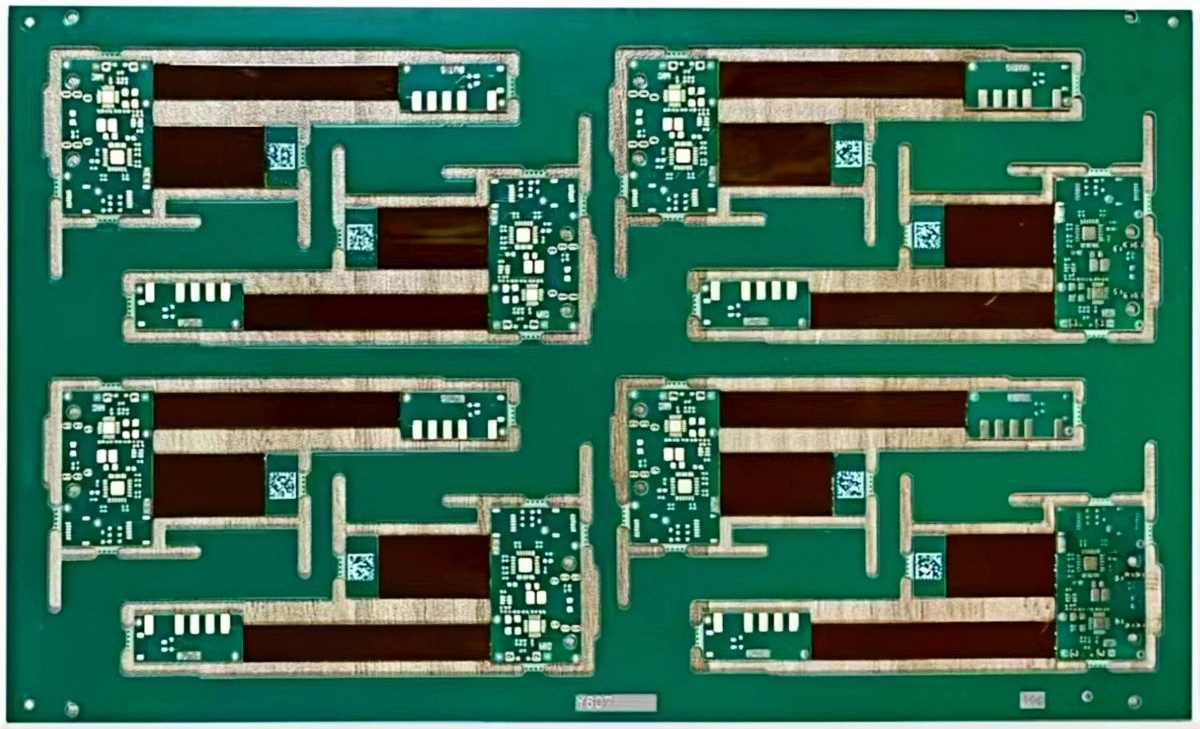

Flexible PCB materials

Flexible PCB Materials form the substrate, conductive layers, and protective coatings of a flexible circuit. In essence, they perform the same basic function as the FR-4 laminates used in rigid PCBs but with key differences in mechanical properties, chemical stability, and processability.

Most Flexible PCB Materials consist of three primary elements:

Base film (often polyimide or polyester): Provides mechanical stability and flexibility.

Conductive layer (typically copper foil): Transmits electrical signals.

Adhesive or bonding agents: Secure the conductive foil to the base film, sometimes eliminated in advanced adhesiveless constructions.

The synergy of these layers defines the performance envelope of a flexible circuit. High-temperature polyimide films, for example, offer excellent thermal stability and chemical resistance. Copper foils vary in grain structure and ductility, influencing how well the circuit can bend or twist without cracking.

A key differentiator of Flexible PCB Materials is their ability to endure repeated flexing. This is quantified by parameters like minimum bend radius, flexural modulus, and fatigue life. Polyimide-based substrates can withstand tens of thousands of flex cycles, making them suitable for dynamic flex applications such as foldable devices or moving hinges in laptops.

Signal integrity depends on stable dielectric properties across a range of frequencies. Flexible PCB Materials should maintain consistent dielectric constants (Dk) and dissipation factors (Df) even under mechanical stress. This ensures that high-speed signals travel with minimal loss or distortion.

Electronics generate heat; therefore, thermal conductivity and heat resistance are crucial. Polyimide films can tolerate temperatures up to 200°C or higher, whereas cheaper polyester substrates may soften at lower temperatures. Selecting the right material involves balancing cost, performance, and environmental conditions.

Because not all applications have the same requirements, there are several categories of Flexible PCB Materials. Each type comes with distinct properties and optimal use cases.

Polyimide (PI) is the gold standard for high-performance Flexible PCB Materials. It offers:

High thermal stability

Excellent chemical resistance

Superior mechanical flexibility

Polyimide-based materials are common in aerospace, automotive, and medical electronics, where reliability trumps cost considerations.

PET is often used in cost-sensitive applications where extreme temperatures are not expected. It provides adequate flexibility and dielectric strength but may limit soldering processes. Key advantages include low cost and suitability for mass-market consumer devices.

Traditional flexible circuits use adhesives to bond copper foil to the base film. However, adhesives can introduce thickness, reduce flexibility, and limit high-frequency performance. Adhesiveless Flexible PCB Materials use direct deposition or laminating methods, improving signal performance and bend endurance.

Flexible PCB Materials employ copper foils with different manufacturing processes:

Rolled-Annealed (RA) Copper Foil: Produced by mechanical rolling, resulting in a smoother surface and higher ductility. Ideal for dynamic flexing.

Electrolytic Copper Foil: Deposited via electroplating, offering higher tensile strength but less ductility. Cost-effective for static flex applications.

This distinction affects the life span and reliability of flexible circuits.

Emerging materials like liquid crystal polymer (LCP) and PTFE-based substrates are gaining traction. These offer ultra-low moisture absorption, exceptional high-frequency performance, and stable dielectric properties, making them suitable for 5G and RF/microwave applications.

Reliability is arguably the most critical criterion when selecting Flexible PCB Materials. It dictates the product’s lifespan, its tolerance to stress and environmental changes, and ultimately the reputation of the device or brand. A flexible circuit may pass initial tests but fail prematurely if the underlying materials are not well matched to the application.

Flexible circuits are frequently bent, folded, or twisted. Minimum bend radius — the tightest radius without inducing cracks — is a key specification. Rolled-annealed copper foil paired with high-temperature polyimide films consistently delivers superior bend endurance. Adhesive-based laminates typically exhibit lower fatigue life due to interlayer stresses.

Many applications — especially automotive and industrial — expose Flexible PCB Materials to oils, fuels, humidity, and corrosive gases. Polyimide and liquid crystal polymer films have superior chemical resistance compared to PET, which can absorb moisture and swell, affecting dielectric properties. For harsh environments, protective coverlays and conformal coatings add another barrier.

Repeated heating and cooling can induce mechanical stresses between copper and the base film. High glass-transition temperature (Tg) adhesives and polyimide substrates can mitigate delamination or cracking. Designers should consider coefficient of thermal expansion (CTE) mismatches to prevent mechanical stress buildup.

As the board flexes, the geometry of traces can slightly change, altering impedance and crosstalk. Low-loss dielectrics maintain stable electrical properties under strain, which is essential for high-speed or RF signals. In some cases, symmetrical stack-ups help reduce warping.

While mechanical durability is essential, thermal and electrical performance often determine whether a flexible circuit meets its specification.

Thermal Conductivity: Flexible substrates are generally less thermally conductive than rigid laminates. Designers often integrate thermal vias or stiffeners for heat spreading.

Operating Temperature Range: Polyimide materials can survive >200 °C during soldering or reflow, whereas PET deforms at lower temperatures.

Heat Dissipation Enhancements: Metal stiffeners or thin copper planes can help dissipate heat but may compromise flexibility.

Dielectric constant (Dk) and loss tangent (Df) define how signals propagate. Materials like PTFE and LCP exhibit very low Dk/Df, making them attractive for high-frequency circuits such as antennas or 5G transceivers. Even small variations in Dk across the flex area can produce measurable impedance mismatches.

As devices get smaller, proximity of high-speed lines to sensitive analog circuits can create EMI issues. Flexible circuits can incorporate embedded ground planes or flexible shielding films to control noise. However, these additions must be carefully balanced with bendability.

Material selection alone is not enough — engineers must adopt design strategies that complement the inherent properties of Flexible PCB Materials.

Place traces perpendicular to the bend axis to reduce stress.

Use staggered or curved traces rather than sharp corners.

Minimize via count in bend areas.

Thinner copper layers and adhesiveless constructions improve flexibility. Designers can alternate copper thicknesses to balance stresses. Coverlay openings should accommodate dynamic flexing.

Strategically placed stiffeners (polyimide, FR-4, or metal) can provide mechanical support to connector areas without compromising the flex region. Proper bonding and CTE matching are essential to prevent delamination.

Even the best Flexible PCB Materials can be damaged during assembly. Limiting the number of reflow cycles, using low-stress connectors, and careful routing of cables can greatly extend service life.

Although rigid PCBs still dominate the electronics market, Flexible PCB Materials introduce a set of advantages that rigid substrates can’t match. Understanding these contrasts helps designers pick the optimal solution.

Rigid PCBs are made from glass-reinforced epoxy laminates (FR-4), which are strong but brittle. Flexible PCB Materials — such as polyimide or LCP films — allow bending, folding, and dynamic movement without cracking. This mechanical versatility enables 3D packaging, wearable integration, and miniaturized devices.

Flexible PCBs often weigh significantly less than their rigid counterparts, thanks to thin base films and low copper thickness. Reducing weight and volume improves portability and fuel efficiency in aerospace and automotive applications.

By using Flexible PCB Materials, engineers can replace multiple rigid boards and connectors with a single continuous flex circuit. This reduces assembly time, improves reliability, and cuts overall cost.

Rigid PCBs typically exhibit stable dielectric properties due to their glass-reinforced substrates. However, advanced Flexible PCB Materials such as PTFE or LCP can achieve even lower dielectric losses, particularly beneficial for RF and microwave circuits.

Environmental compliance is now a baseline requirement for global manufacturing. Designers must ensure that Flexible PCB Materials meet stringent standards for safety, recyclability, and chemical usage.

Most suppliers of Flexible PCB Materials offer RoHS-compliant laminates (lead-free, halogen-free). REACH regulations restrict hazardous substances, ensuring long-term safety for workers and end users.

Flammability ratings (UL94) are crucial for automotive, aerospace, and industrial electronics. Some polyimide films include flame-retardant additives without compromising flexibility.

While recycling flexible PCBs is more challenging than rigid boards, material advances — such as solvent-recoverable adhesives — can improve end-of-life processing. Selecting Flexible PCB Materials with lower environmental impact aligns with corporate sustainability goals.

The versatility of Flexible PCB Materials makes them indispensable in new and rapidly evolving fields.

Fitness trackers, smartwatches, and health-monitoring devices all rely on ultra-thin, flexible circuits that can conform to body contours. Low-profile polyimide or LCP substrates are favored for comfort and reliability.

As vehicles integrate more electronics for ADAS, infotainment, and electrification, Flexible PCB Materials provide weight savings and improved vibration resistance. High-temperature stability ensures performance under the hood.

Catheters, implantable sensors, and diagnostic tools benefit from the biocompatibility and miniaturization offered by Flexible PCB Materials. Materials with low moisture absorption and stable dielectric constants are particularly important for reliability in the human body.

Foldable smartphones and laptops need circuits that endure thousands of folding cycles. Rolled-annealed copper foils combined with ultra-thin polyimide films are typically used here.

Throughout this article, we have explored the multifaceted nature of Flexible PCB Materials — from their core composition and mechanical attributes to thermal performance, environmental considerations, and emerging applications. We’ve seen how these materials enable new product designs and why selecting the right substrate is about much more than simple flexibility.

Key takeaways include:

Flexible PCB Materials come in various types (polyimide, polyester, PTFE, LCP, adhesiveless) to suit different environments and performance goals.

Reliability depends on careful alignment of material properties, design strategy, and manufacturing processes.

Testing and validation — including bend cycle testing, impedance measurements, and thermal cycling — are essential before mass production.

Industry leaders like JM PCB can provide the expertise, rapid prototyping, and quality assurance needed to bring advanced flexible circuits to market.

Looking ahead, advances in ultra-thin films, embedded components, and new conductive materials will continue to push boundaries. Yet no matter how sophisticated the technology becomes, success still hinges on sound material science, thoughtful design, and trusted manufacturing partnerships.

Q1. What factors determine the minimum bend radius of Flexible PCB Materials?

The minimum bend radius depends on total thickness, copper foil ductility, and substrate flexibility. Rolled-annealed copper foil, thinner dielectric layers, and adhesiveless constructions allow tighter bends. Always follow IPC-2223 guidelines to calculate minimum bend radius for your design.

Q2. Can Flexible PCB Materials be combined with rigid sections in the same board?

Yes. Rigid-flex construction combines stiff FR-4 sections with flexible interconnects, allowing connectors, stiffeners, or components to be mounted on the rigid area while using the flex area for movement or folding. This approach gives structural stability without sacrificing flexibility.

Q3. How does moisture absorption affect Flexible PCB Materials?

Materials with high moisture absorption can experience dielectric constant changes, dimensional instability, or adhesion loss. Polyimide and PET have moderate absorption, while LCP exhibits extremely low moisture uptake, making it ideal for high-frequency or humid environments.

Q4. Are there special assembly requirements for Flexible PCB Materials?

Yes. Flexible circuits should be handled carefully to avoid kinking or over-bending during assembly. Low-stress connectors, controlled reflow profiles, and proper support fixtures can help maintain the integrity of Flexible PCB Materials during manufacturing.

Q5. How do coverlays differ from solder masks in Flexible PCB Materials?

Coverlays are flexible polyimide or polyester films laminated over copper to provide insulation and mechanical protection. Solder masks are typically liquid photoimageable coatings used in rigid boards. Coverlays offer better mechanical durability and flexibility, while solder masks are more suited to rigid surfaces.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote