In the landscape of modern electronics, the term Heatsinking Solutions refers to a broad and evolving set of engineering strategies designed to transfer heat away from components, conductive layers, and circuit subsystems within a printed circuit board. While the phrase is often associated with metal heat spreaders or external cooling hardware, in PCB fabrication it has a much more nuanced meaning.

Heatsinking Solutions are structural, material, and design methodologies engineered into the PCB to improve thermal conduction, reduce hot-spot formation, and maintain components within safe operating temperatures across their full power range. Unlike standalone mechanical heatsinks, these PCB-integrated solutions become part of the board’s architecture, affecting stack-ups, copper distribution, via patterns, plating thickness, and interface materials.

In simpler terms, they form the thermal backbone of the PCB—quietly supporting all heat-generating components and enabling power density that would otherwise be impossible using traditional cooling strategies.

The true scope of Heatsinking Solutions is wide and touches nearly every part of board design and fabrication:

Conductive materials such as thick-copper layers

Multi-layer heat-spreading structures

Via arrays designed for vertical thermal transfer

Component-package interfaces (thermal pads, slugs, or solder-filled reservoirs)

Metal-core substrates

Embedded copper blocks or bars

Integration of thermal interface materials (TIMs)

These techniques allow designers to treat the PCB not merely as an electrical backbone, but as an active thermal asset.

In power electronics, automotive systems, RF modules, LED arrays, and high-speed devices—where even small thermal gradients can degrade performance—these solutions determine whether the system ultimately succeeds or fails.

The electronics industry has changed. Devices are smaller. Power density is higher. Thermal budgets are tighter. Designers push PCBs harder, with little physical space for external heatsinks. A formal understanding of what Heatsinking Solutions truly encompasses is critical for aligning electrical, mechanical, and thermal engineering practices.

As someone who has observed the rapid shift toward compact and high-power systems, I believe the definition of Heatsinking Solutions continues to expand. More importantly, it is evolving toward a material-centric discipline—one where the PCB itself becomes the thermal manager, not just the circuit carrier. This shift will redefine the role of fabricators and materials suppliers in the coming decade.

Heatsinking Solutions

The demand for sophisticated Heatsinking Solutions has grown significantly as the industry pushes toward extreme power density and miniaturization. Several trends explain the urgency.

Across sectors—including industrial power modules, EV inverters, and server-grade computing—designers must push more current through smaller footprints. Traditional heatsinks and cooling plates cannot scale down proportionally, meaning the PCB must absorb much more of the thermal load.

Instead of heat spreading across the board, modern devices concentrate significant wattage in tiny packages:

GaN and SiC devices

High-brightness LEDs

PMICs and VRMs

High-frequency communication modules

These components may dissipate 5–50 W in areas smaller than a fingernail. Only advanced Heatsinking Solutions can maintain stable conditions in such scenarios.

FR-4 remains the workhorse of PCB fabrication, but its thermal conductivity—around 0.3 W/m·K—is fundamentally insufficient for today’s demands. Without additional thermal paths, boards fail prematurely.

Automotive and aerospace industries now impose more rigid requirements for:

Thermal cycling

High-temperature exposure

Mechanical shock and vibration

Lifetime temperature gradients

Heatsinking Solutions mitigate these stresses by reducing expansion mismatches and maintaining stable thermal profiles.

The rise of SiC and GaN is the most significant disruptor. These devices run hotter, switch faster, and generate more localized thermal stress. PCBs must adapt accordingly.

The core purpose of integrating Heatsinking Solutions into PCB fabrication is to create controlled, predictable, and highly conductive pathways that move heat away from critical components. Without these engineered pathways, thermal energy will accumulate at the device junction, leading to elevated temperatures, stress, and premature failure.

A thermal path describes how heat travels:

from the component junction

through the package

into the solder joint

across the copper pad

through vias or planes

and finally into ambient or mechanical heatsinking structures

Every segment has different thermal conductivity. The total thermal resistance determines whether a device runs at safe temperatures or exceeds its limit.

Integrated Heatsinking Solutions—such as thermal vias, copper pours, embedded metal cores, and thick copper structures—lower the effective thermal resistance of the PCB.

They achieve this by:

providing larger cross-sectional copper areas

enabling vertical heat transfer

spreading heat laterally across planes

reducing bottlenecks caused by dielectric materials

enhancing conductivity through metalized vias

In many cases, adding a well-designed thermal via network can reduce device temperatures by 10–25°C, which significantly affects reliability and lifespan.

The power of Heatsinking Solutions lies in how they combine. Copper planes alone are effective. Thermal vias alone are effective. But when combined with thick copper, optimized footprints, and TIM interfaces, they create synergistic thermal channels with 3× to 8× greater efficiency.

This layered approach allows engineers to target:

isolated hot spots

high-current switching nodes

dense clusters of components

power semiconductors

RF amplifiers

The result is a board that behaves more like a thermal machine than a simple electrical interconnect.

Heatsinking Solutions play an essential role in three critical aspects of performance: power density, component reliability, and service life. These three factors form the engineering triangle that dictates what a PCB can ultimately achieve.

Modern devices require designers to pack more transistors, more drivers, and more converters into smaller volumes. Higher power density is only possible when thermal energy is efficiently evacuated.

Heatsinking Solutions allow engineers to:

place power MOSFETs or SiC devices closer together

use smaller packages without overheating

reduce the size of external heatsinks

increase switching frequencies (which reduces magnetics size)

design compact converters, LED engines, and RF modules

Without strong thermal pathways built directly into the PCB, these modern architectures would not be feasible.

Semiconductor reliability is highly temperature-sensitive. Every 10°C of temperature reduction can improve component lifespan by approximately 2× (a widely accepted rule derived from Arrhenius acceleration models).

Well-implemented Heatsinking Solutions directly lower:

junction temperature

solder joint stress

substrate warpage

derating factors

thermal cycling fatigue

This is especially critical for:

automotive electronics exposed to 150°C

LED applications where lumen degradation is temperature-driven

power supplies running at high switching speeds

telecom and server systems operating under continuous load

PCBs operating at lower temperatures exhibit:

lower oxidation rates

better dielectric integrity

reduced creep corrosion

less via cracking

improved copper adhesion

Thermal uniformity is equally important. Sharp gradients between a hot IC and surrounding regions create mechanical stress and bending moments. Heatsinking Solutions reduce these gradients and ensure long-term structural integrity.

Every Heatsinking Solution used in PCB fabrication relies on predictable thermal behavior of materials. Understanding these foundations helps designers anticipate performance limits.

| Material | Typical Thermal Conductivity (W/m·K) |

|---|---|

| Copper | 380–400 |

| Aluminum | 200–220 |

| FR-4 Dielectric | 0.25–0.35 |

| High-Tg Resin Systems | 0.35–0.6 |

| Metal-Core Substrates (Aluminum) | 1–3 (dielectric), 200 (metal) |

| Ceramics (AlN, Alumina) | 20–170 |

The significant jump from 0.3 W/m·K (FR-4) to >300 W/m·K (copper) shows why vertical and horizontal copper structures dominate thermal engineering.

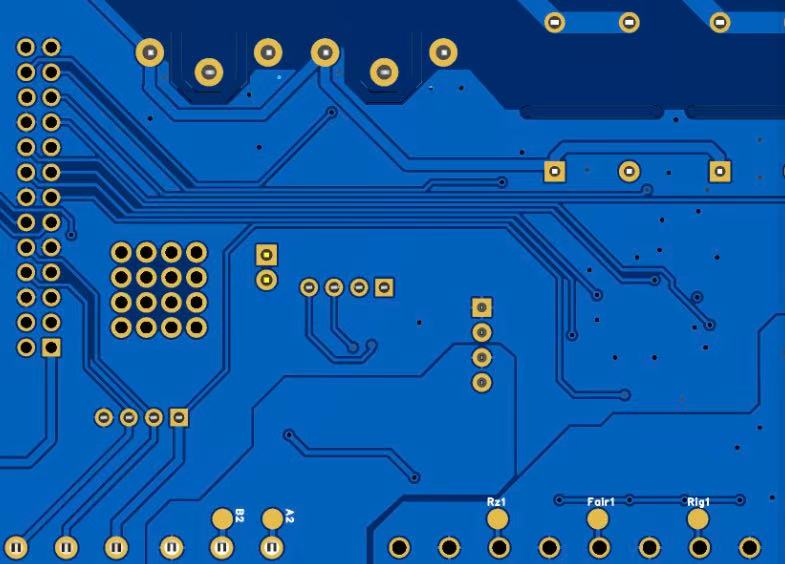

Board-level Heatsinking Solutions form the foundation of thermal performance in modern PCBs. They determine how heat travels horizontally and vertically across the entire board, and they often contribute the highest thermal conductivity compared with any other method integrated into the PCB stack.

Large-area copper planes—traditionally used for power or ground reference—also function as natural heat spreaders. Their high conductivity (≈ 400 W/m·K) allows thermal energy to move laterally with minimal resistance.

Effective copper plane–based Heatsinking Solutions include:

continuous ground planes beneath power devices

mirrored copper areas on multiple layers

copper balancing to avoid thermal-mechanical warpage

staggered or connected planes for smoother heat transfer

Copper planes are especially valuable where:

multiple devices generate heat simultaneously

the designer must avoid hot-spot aggregation

thermal uniformity directly affects electrical integrity (e.g., RF systems, BGA assemblies)

Thermal vias bridge the gap between component pads and internal copper planes. Their goal is to transfer heat vertically through the stack, bypassing the low-conductivity dielectric layers.

Key configurations include:

via arrays under power packages (QFN, DPAK, D2PAK)

microvias in HDI stack-ups for high-density regions

filled and capped vias to maintain solder integrity

via-in-pad structures for high-power amplifier modules

The thermal resistance improvement can be dramatic: a well-designed via array can drop junction temperatures by 15–30°C under typical load.

Some PCB stack-ups incorporate dedicated thermal-spreading layers—solid copper plates or thick copper sub-layers designed purely for conduction.

These layers may be:

2–4 oz copper

integrated stiffeners

hybrid copper-aluminum zones

They turn the PCB into a wide-area heatsink, supporting even the most aggressive thermal loads.

Component-level Heatsinking Solutions focus on optimizing the heat path from the device package into the PCB. This is where heat originates, making these strategies crucial to managing initial thermal bottlenecks.

Many modern semiconductors include exposed thermal pads. These pads must be connected to copper pours and thermal vias to function effectively.

Key strategies include:

solder mask opening matched precisely to package geometry

optimized solder volume to reduce voiding

direct connection to internal copper layers

use of filled vias under exposed pads

Because thermal pads sit at the interface between component and PCB, they are the most sensitive location for thermal failure.

Solder itself has moderately good conductivity. When optimized, the solder layer forms a robust thermal bridge. However, voiding or excessive standoff reduces heat transfer.

Engineers should consider:

stencil design

pad geometry

reflow profile

choice of solder alloy

Even a 5–10% change in voiding levels can affect junction temperature stability.

Thermal coins (or slugs) are metal blocks—usually copper or aluminum—embedded directly beneath heat-generating devices. They provide:

extremely low thermal resistance

direct mechanical conduction

structural stability

These Heatsinking Solutions can reduce junction temperatures by 20–50°C, making them popular in LED modules, RF amplifiers, and high-current MOSFETs.

Achieving higher power density in modern electronics is no longer a matter of simply increasing copper thickness or placing a heatsink on top of a high-power device. The real engineering challenge lies in integrating Heatsinking Solutions directly into the PCB fabrication process, enabling heat to be controlled at its origin instead of being managed only as an afterthought. Through a combination of heavy-copper planes, plated thermal vias, metal-core substrates, embedded copper coins, and thermally optimized material systems, PCBs are increasingly becoming active participants in system-level thermal engineering.

One of the most important realizations, supported by real-world manufacturing data, is that thermal reliability is always the sum of many small decisions: material choice, layer stacking, surface finish, thermal path continuity, and the geometry of copper features. Even minor errors—such as mismatching substrate thermal conductivity or selecting a poorly performing TIM—can cripple the effectiveness of otherwise well-designed Heatsinking Solutions. This is why close collaboration with an experienced PCB manufacturer is essential. Partners such as JM PCB not only provide advanced fabrication capabilities but also assist engineers in selecting correct materials, layer structures, and thermal strategies before the design even reaches production.

As power-density requirements continue to climb in 5G systems, EV power modules, renewable-energy inverters, consumer electronics, and industrial automation, integrated Heatsinking Solutions will only grow more crucial. Designers who embrace early-stage thermal planning will see fewer failures, longer product lifespans, and improved performance stability. Conversely, those who continue to rely on reactive or superficial cooling strategies will increasingly struggle with heat-induced degradation.

Ultimately, thermal engineering is not merely about keeping components cool—it is about enabling innovation. The ability to safely increase power density opens the door to smaller devices, faster switching speeds, greater efficiency, and more compact architectures. When the PCB itself becomes a thermal asset instead of a thermal bottleneck, the entire system benefits. That is the fundamental value of well-designed and well-manufactured Heatsinking Solutions, and it is the direction that the future of high-power PCB fabrication is undeniably moving toward.

Rolled copper foil is produced by mechanically rolling copper into thin sheets, resulting in excellent ductility and a smoother surface. Electrolytic copper foil is deposited from a chemical bath, offering higher tensile strength and lower cost while remaining suitable for rigid PCB manufacturing.

No. While MCPCBs offer excellent thermal conductivity, many designs achieve strong thermal performance using heavy-copper layers, filled thermal vias, or embedded copper coins. The best solution depends on power density, allowable thickness, and cost targets.

Thermal vias create vertical heat paths that transfer energy from hot components to internal copper planes or the PCB’s opposite side. When arranged in high-density arrays, they significantly reduce thermal resistance around power devices.

Materials determine baseline thermal conductivity, glass-transition temperature, expansion behavior, and long-term reliability. Choosing the wrong substrate can overwhelm even the best Heatsinking Solutions, especially in power electronics and RF systems.

Copper coins are solid metal blocks embedded into the PCB to create a direct thermal path beneath high-power components. They dramatically reduce junction temperature and are commonly used in automotive LEDs, power modules, and telecom systems.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote