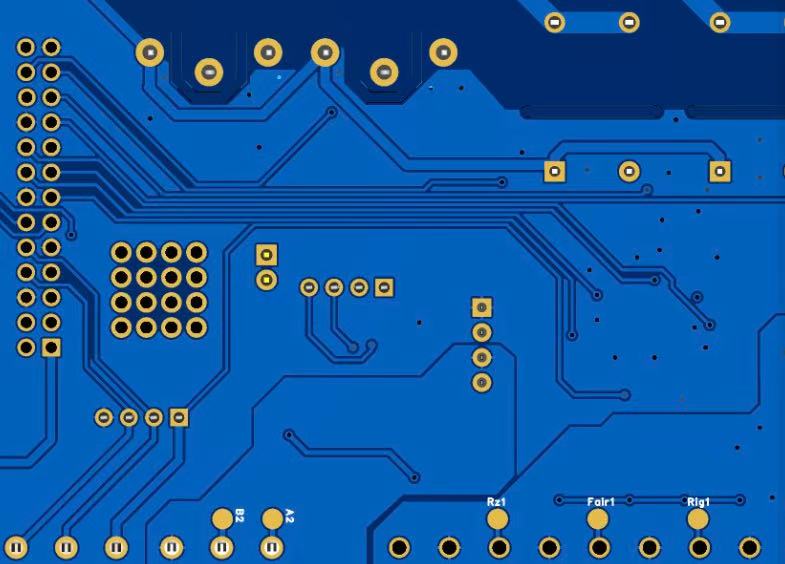

The Blue Circuit Board is not merely a product of visual preference—it is a combination of chemistry, light physics, and material science. At its core, a blue PCB is identical in electrical structure to other boards: it consists of copper traces laminated between dielectric layers, all protected by a solder mask. However, the blue solder mask—typically made of epoxy or liquid photoimageable (LPI) material—has unique optical and material properties that distinguish it from green, red, or black alternatives.

The pigments used in blue solder masks tend to scatter light differently, providing a cooler and sharper contrast under bright inspection lights. Engineers working under magnification or with automated optical inspection (AOI) tools often find that blue solder masks offer excellent visibility for fine traces and microvias. This clarity makes troubleshooting and rework easier, particularly for dense multilayer boards or prototypes.

From an aesthetic standpoint, the Blue Circuit Board conveys a premium feel. It’s often chosen by startups and product designers who want their prototypes or consumer boards to stand out. Unlike the conventional green PCB that communicates industrial maturity, the blue hue gives a sense of futuristic engineering—making it particularly appealing for Internet of Things (IoT) devices, wearable technology, and medical instrumentation.

Blue Circuit Board

In modern electronics, the external appearance of a device—down to the color of its circuit board—can influence how the product is perceived. The Blue Circuit Board has become a tool for visual branding. Companies use it to differentiate their hardware from competitors and to communicate a sense of reliability blended with innovation.

Think about the subtle impact of opening a high-end piece of hardware. The blue color instantly signals care in design and attention to detail. While a consumer may never consciously compare PCB colors, engineers and investors notice. A consistent brand language across the internal and external design of a product fosters trust and recognition.

This is particularly true in industries where transparency and innovation are essential to the brand message. For instance, many open-source hardware companies and research-oriented startups use blue PCBs to reflect openness and clarity in their engineering philosophy. The Blue Circuit Board becomes an emblem—a quiet statement that technology can be both functional and beautiful.

Structurally, a Blue Circuit Board consists of several key materials: the copper foil (for circuitry), the dielectric substrate (commonly FR-4), the prepreg layers (bonding material), and the blue solder mask. The solder mask, while thin compared to other layers, plays a critical role not just in protection but also in optical behavior.

The pigments used in blue solder masks can slightly influence UV curing times, depending on their formulation. For instance, darker shades may absorb more light energy, requiring adjustments during photolithography. However, advanced manufacturing facilities such as JM PCB have optimized these parameters to ensure that blue masks cure evenly without sacrificing precision.

In terms of performance, the color pigment itself has negligible electrical impact. What matters more is the quality of the solder mask resin, its adhesion, and its thickness uniformity. A well-applied blue solder mask provides strong resistance against oxidation, flux contamination, and moisture ingress. This helps extend the service life of the board, particularly in humid or high-temperature environments.

When combined with high-grade copper foil and a properly balanced dielectric constant (Dk), the Blue Circuit Board can achieve signal integrity comparable to—or in some cases superior to—traditional green boards.

When evaluating the Blue Circuit Board, cost is one of the first practical considerations. Blue PCBs tend to be slightly more expensive than standard green boards—typically by 5% to 10%. This difference arises primarily from the pigment cost, manufacturing yield adjustments, and production line specialization.

In high-volume manufacturing, green solder mask materials are purchased in bulk and standardized across multiple product lines. Blue solder masks, however, are often produced in smaller quantities, which leads to higher unit costs. Additionally, color consistency checks and curing adjustments can add minor process time.

However, this added cost is often offset by improved design perception and product differentiation. For companies building prototypes or limited-edition devices, the Blue Circuit Board can serve as a valuable branding element. From a psychological perspective, it transforms an otherwise utilitarian component into a visual asset.

From an engineering standpoint, blue solder mask materials sometimes exhibit slightly different thermal expansion properties or hardness, depending on the supplier. These differences are negligible in most consumer-grade products but may be relevant in high-frequency or high-density designs. Engineers evaluating cost-performance trade-offs should consider these aspects when selecting board materials.

From a purely electrical perspective, the color of the solder mask—blue, green, red, or black—does not inherently change conductivity or signal behavior. However, the Blue Circuit Board can indirectly influence performance through its surface quality, solderability, and heat resistance.

In RF and high-speed digital designs, where even minute variations in dielectric constant can affect signal propagation, consistency is paramount. Some blue solder mask formulations offer superior smoothness and adhesion, reducing the risk of microbubbles or delamination under heat stress. This contributes to improved reliability during solder reflow and long-term operation.

The reflection characteristics of blue masks also assist automated inspection systems by enhancing contrast between traces and non-circuit areas. Fewer false positives in AOI mean higher first-pass yield—a subtle but significant performance advantage in mass production.

Furthermore, the heat resistance of a Blue Circuit Board plays an important role during assembly. A stable blue solder mask minimizes discoloration or charring during reflow, maintaining both functional and visual integrity even after multiple thermal cycles.

When comparing the Blue Circuit Board to the traditional green PCB, one must examine not only visual differences but also manufacturing, performance, and inspection implications. Green PCBs have dominated the market for decades primarily due to mature supply chains, consistent pigment chemistry, and reliable contrast ratios for optical inspection.

However, the Blue Circuit Board introduces distinct advantages in certain contexts. Its color contrast under bright white or UV inspection lighting tends to enhance trace visibility, particularly for small-pitch designs and fine copper features. This is why many prototype engineers and R&D labs prefer blue PCBs—they simplify manual inspection and documentation, where visual clarity matters as much as electrical function.

In terms of process compatibility, both blue and green boards can support the same surface finishes, such as HASL, ENIG, immersion silver, or OSP. Yet, it’s been observed that the blue solder mask often provides a smoother surface texture, allowing for slightly more uniform solder joints during assembly. This can translate to marginally improved solder joint reliability and aesthetics—factors that, while minor in high-volume consumer products, become meaningful in low-volume, high-value applications like aerospace modules or prototype circuits.

From a psychological standpoint, engineers often describe the Blue Circuit Board as “cleaner” and “calmer” to work with. While these impressions may sound subjective, they play a real role in product perception and workplace experience. The color blue tends to reduce eye strain during inspection, particularly under magnification lamps used in fine-pitch soldering. Green, though historically favored, can appear slightly reflective and fatiguing over long inspection sessions.

The most common debate in PCB aesthetics and performance revolves around blue vs. green. The Blue Circuit Board has become popular in premium and design-oriented products, while the green PCB remains the industry standard due to its balance of cost, performance, and manufacturability. Below is a comparative overview highlighting key distinctions:

| Parameter | Blue Circuit Board | Green Circuit Board |

|---|---|---|

| Solder Mask Visibility | High contrast with silkscreen; moderate visibility of traces | Excellent visibility of traces and defects |

| Cost | Slightly higher (≈5–10%) | Lower, mass-production standard |

| Aesthetic Appeal | Modern, professional, premium | Traditional, reliable, industrial |

| Thermal Emissivity | Slightly higher (better heat radiation) | Moderate |

| Inspection Efficiency | Requires adjusted AOI settings | Easy manual and AOI inspection |

| Market Perception | High-end and tech-forward | Economical and dependable |

It’s evident that while green PCBs dominate the industry for practicality, Blue Circuit Boards carve out a niche in sectors emphasizing brand image and visual design. From a strategic viewpoint, product designers should assess their target audience and application environment before deciding. For instance, consumer electronics companies targeting style-conscious markets may find blue PCBs advantageous. On the other hand, high-volume industrial devices might favor the cost efficiency of green solder masks.

When comparing blue vs. green in the realm of printed circuit boards, one must look beyond surface color. The Blue Circuit Board represents more than an aesthetic deviation from industry norms—it is a deliberate choice that symbolizes precision, confidence, and forward-thinking design. Throughout this analysis, we have explored its definition, cost implications, performance characteristics, manufacturing nuances, and even its influence on brand identity.

From a purely technical standpoint, the Blue Circuit Board performs almost identically to its green counterpart. Its thermal, electrical, and mechanical behaviors align closely, thanks to advanced resin and pigment technologies. Yet, what truly differentiates it is how it communicates quality and modernity. In a marketplace where users rarely see the inner workings of electronic devices, engineers and designers are beginning to appreciate that visual presentation can reinforce perceived reliability.

The cost differential—typically just 5–10% higher—is a modest premium for the visual and psychological benefits it confers. When coupled with meticulous production processes, such as those offered by JM PCB, blue solder mask boards achieve excellent consistency, signal performance, and appearance. The slightly higher investment thus becomes a form of brand differentiation.

Moreover, as sustainability and aesthetic engineering converge, the Blue Circuit Board emerges as a medium where design and environmental awareness intersect. Halogen-free, RoHS-compliant materials and low-VOC formulations ensure that the environmental impact remains minimal while achieving vibrant, durable finishes.

In conclusion, the Blue Circuit Board serves as a reminder that even in the domain of precision engineering, visual identity matters. It symbolizes a mature integration of performance and presentation—a bridge between form and function. Companies that adopt it communicate an unspoken message: they value both reliability and refined craftsmanship. As technology continues to evolve, the blue hue will likely remain a statement of innovation, professionalism, and excellence in PCB manufacturing.

Rolled copper foil is produced by mechanically rolling copper into extremely thin sheets. This process creates a dense grain structure with high tensile strength, making it suitable for flexible circuits and applications requiring repeated bending. Electrolytic copper foil, on the other hand, is formed through electro-deposition, offering excellent conductivity and cost efficiency. It is typically used in rigid PCBs where mechanical flexibility is less critical.

In terms of electrical performance, there is virtually no difference. The color of the solder mask does not alter conductivity, impedance, or signal integrity. However, a Blue Circuit Board may offer slightly improved thermal emissivity and a smoother surface finish, depending on the resin and pigment formulation. Its true advantage lies in aesthetics and brand differentiation rather than raw performance.

The blue solder mask ink is produced in smaller quantities and requires more precise processing to ensure color consistency. Additionally, the semi-transparency of blue masks can make inspection more difficult, leading to longer production times and additional quality checks. The overall cost difference is typically 5–10%, which most manufacturers consider reasonable given the professional appearance and branding value of the final product.

Yes. Modern blue solder mask formulations are halogen-free, lead-free, and comply with international environmental standards such as RoHS and REACH. Many manufacturers, including JM PCB, have shifted to low-VOC production processes and improved wastewater treatment systems, ensuring that environmental impact is minimized without compromising the vibrant finish of the blue surface.

Absolutely. A Blue Circuit Board conveys modernity, precision, and premium quality. This is why it is often selected for products that aim to project innovation—such as high-end consumer electronics, IoT devices, and automotive modules. The color’s visual contrast with white silkscreen markings enhances readability and aesthetic clarity, giving your product a sophisticated, professional feel that customers subconsciously associate with superior craftsmanship.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote