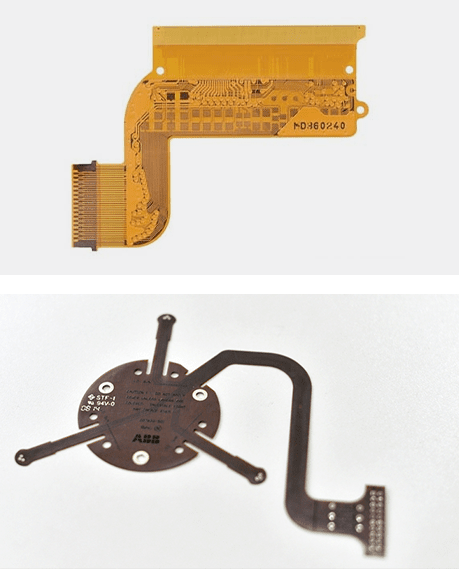

FPCBs are used widely in everyday technology and electronics in addition to high-end,

complex completed components. A few of the most prominent examples of flexible circuits

usage is in modern portable electronics, devices, hard disk drives and desktop printers.

Flexible circuits are also used extensively in other applications and industries including:

Communications

Consumer Electronics

Automotive

Medical

Industrial

Aerospace

Military

Transportation

In transportation they are extensively used due to their improved resistance to vibrations and movement.

The Advantages of Flexible Printed Circuit Boards

Electronic devices have taken upon a prominent part of our everyday lives. The extensive range of devices from cell-phones to servers, regardless of their sizes and uses are now being designed to be flexible, lightweight and efficient. While they all come in diverse shapes, sizes and functionalities, there is one thing in common – they include flexible printed circuits boards.