In the complex world of electronics manufacturing, ensuring that a printed circuit board (PCB) performs exactly as intended is more than just a technical requirement—it is a critical determinant of product reliability and customer satisfaction. Every modern electronic device, from smartphones to medical equipment, relies on PCBs to deliver precise and consistent performance. However, even the most sophisticated manufacturing processes cannot guarantee flawless functionality without a dedicated verification step. This is where Functional Testing (FCT) comes into play.

Functional Testing (FCT) is the final verification step in the manufacturing process, where each PCB is subjected to real-world operational conditions to confirm that it functions as expected. Unlike other forms of testing, which may focus on individual components or electrical characteristics, FCT evaluates the board as a complete system. By simulating real operational scenarios, it can uncover hidden defects, assembly errors, or design oversights that could compromise the end product.

Beyond defect detection, FCT serves as a bridge between manufacturing and quality assurance, ensuring that the PCBs leaving the production line will deliver reliable performance under actual usage conditions. Moreover, it provides manufacturers with critical feedback that can refine production processes and improve overall quality standards.

Functional Testing (FCT)

Functional Testing (FCT) is a comprehensive evaluation procedure performed on PCBs to ensure they meet design specifications and operational expectations. Unlike static testing methods, which primarily measure electrical characteristics or physical integrity, FCT examines the PCB’s behavior under dynamic conditions. This approach is essential for detecting latent defects that may not be evident through visual inspection or in-circuit testing.

The primary purpose of Functional Testing (FCT) is twofold:

Verification of Functionality: FCT confirms that all circuits, components, and subsystems on the PCB perform according to the design requirements. For example, a digital control board must correctly interpret input signals, process data, and generate the appropriate outputs.

Quality Assurance and Reliability: FCT ensures that PCBs leaving the production line are free from defects that could cause failure in real-world applications. This not only protects the manufacturer’s reputation but also reduces costly returns and warranty claims.

In essence, Functional Testing (FCT) transforms theoretical designs into validated, market-ready products.

The concept of Functional Testing (FCT) has evolved alongside PCB manufacturing technology. In the early days, testing was limited to simple continuity checks and voltage measurements. As electronic devices became more complex, with multi-layered boards and high-density components, traditional methods proved insufficient to guarantee performance.

Functional Testing (FCT) emerged as a response to these challenges, providing a structured approach to evaluate a PCB under conditions that mimic real-life operation. Over time, FCT has incorporated automation, advanced simulation tools, and integrated software to handle increasingly complex designs. Today, FCT is considered a standard best practice in industries where reliability is critical, such as aerospace, medical devices, automotive electronics, and high-performance computing.

Successful Functional Testing (FCT) requires a combination of hardware, software, and well-designed procedures. Key components include:

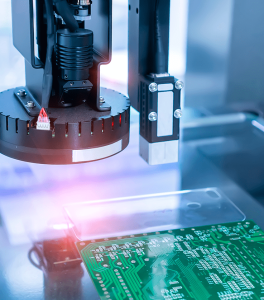

Test Fixtures and Jigs: These physically connect the PCB to testing instruments while ensuring proper alignment and signal integrity. Custom fixtures are often designed for each specific PCB type.

Signal Generators and Oscilloscopes: These devices simulate inputs and monitor outputs, allowing engineers to verify proper signal processing and timing.

Automated Test Software: Software platforms control test sequences, record data, and identify failures with high precision. Automation reduces human error and speeds up the testing process.

Power Supplies and Load Simulators: These replicate real operating conditions, including voltage fluctuations and current loads, to assess the PCB’s response.

In combination, these tools allow for thorough evaluation of both functional and operational performance, ensuring that no aspect of the PCB’s behavior is left unchecked.

Functional Testing (FCT) plays a pivotal role in guaranteeing that a PCB meets its design requirements and performs reliably in its intended application. The process ensures that all electronic pathways, components, and subsystems interact correctly, under both normal and stressed conditions. Here’s how FCT ensures PCB performance:

Verification of Electrical Integrity: FCT tests each input and output channel on the PCB to confirm proper signal flow and voltage levels. This detects shorts, open circuits, and other assembly-related defects.

Component Function Validation: Each integrated circuit, resistor, capacitor, and other component is evaluated to ensure it performs its designated function. For example, timing circuits are tested for accurate clock signals, and power circuits are verified for proper voltage regulation.

System-Level Behavior Assessment: Unlike isolated testing, FCT examines the PCB as a complete system. It verifies that software-driven functions, control logic, and signal processing all operate in harmony.

Stress and Environmental Testing: FCT often incorporates conditions such as temperature variations, voltage fluctuations, and load stresses. This ensures the PCB can withstand real-world usage without degradation or failure.

By applying these checks, Functional Testing (FCT) ensures that PCBs will operate reliably in their final applications, reducing the likelihood of field failures and costly recalls. Manufacturers like JM PCB have successfully integrated comprehensive FCT protocols, which has helped them maintain high customer satisfaction and a reputation for delivering robust PCBs.

The Functional Testing (FCT) process can be divided into several key stages, each designed to verify a specific aspect of PCB functionality:

Preparation and Setup: The PCB is placed in a custom test fixture and connected to testing instruments. Power supplies, signal generators, and automated test systems are calibrated to match the board’s specifications.

Initial Power-On Test: Before applying operational signals, the PCB undergoes a basic power-on test to check for shorts, excessive current draw, and immediate failures.

Signal Input and Output Testing: Controlled input signals are applied to the PCB, and corresponding outputs are measured. This step validates that data processing, communication channels, and component responses are accurate.

Functional Scenario Simulation: The PCB is subjected to a series of functional scenarios that simulate real-world operations. For instance, a control board may be tested with varying sensor inputs, while an audio board may be evaluated for signal clarity and noise levels.

Data Logging and Analysis: Automated test software records all measurements and compares them to expected performance thresholds. Any deviations are flagged for further investigation.

Pass/Fail Determination: Based on the results, the PCB either passes the test and moves to packaging, or fails and is sent for rework or further analysis.

This structured workflow ensures that every PCB leaving the production line has undergone rigorous scrutiny, confirming both component functionality and system-level performance.

Despite its importance, Functional Testing (FCT) comes with several challenges:

Complexity of Modern PCBs: High-density boards with multiple layers, fine-pitch components, and mixed signal designs require sophisticated test setups and precise control of signal timing.

Fixture and Equipment Costs: Designing and building custom test fixtures for each PCB type can be expensive and time-consuming, particularly for prototypes or low-volume production runs.

Test Coverage vs. Test Time: Comprehensive testing may require extended time, which can affect production throughput. Balancing thoroughness with efficiency is an ongoing challenge.

Identifying Intermittent Faults: Some defects only manifest under specific conditions or after extended use, making them difficult to detect during standard FCT.

Integration with Production Workflow: Ensuring FCT aligns seamlessly with manufacturing schedules and other quality checks requires careful planning and coordination.

Overcoming these challenges often involves a combination of advanced automation, well-designed test software, and continuous process improvement.

Successful Functional Testing (FCT) begins long before a PCB enters the test fixture. Proper planning and preparation are essential to ensure accurate, efficient, and comprehensive verification. Key best practices include:

Defining Test Objectives: Clearly outline what the FCT process aims to verify. Are you confirming signal integrity, validating control logic, or simulating real-world environmental conditions? A well-defined scope ensures relevant tests are performed.

Understanding PCB Design Specifications: Detailed knowledge of the PCB layout, components, and circuitry is critical. This helps anticipate potential failure points and design appropriate test scenarios.

Preparing the Test Environment: Environmental factors such as temperature, humidity, and power supply stability can affect test outcomes. Ensuring a controlled environment increases reliability and repeatability of results.

Documenting Procedures: Every step of the FCT process should be documented, from setup to data analysis. Clear procedures reduce human error and facilitate training of new engineers.

By investing time in planning, manufacturers can minimize test failures, improve throughput, and ensure consistent quality across production batches.

Designing effective test cases is at the heart of Functional Testing (FCT). Test cases define how each PCB will be evaluated and which scenarios will be simulated. Best practices for test case design include:

Coverage of All Functional Paths: Every input, output, and internal processing pathway should be evaluated. This ensures that even rarely used features are tested.

Incorporating Boundary Conditions: Testing under extreme conditions—such as voltage fluctuations, temperature extremes, or high data rates—helps identify vulnerabilities before they affect the end user.

Prioritizing Critical Functions: Not all PCB features carry the same risk if they fail. Identify mission-critical circuits and design test cases that rigorously assess their performance.

Automated vs. Manual Test Cases: Automation improves repeatability and speed, but some complex scenarios may require manual observation or intervention. Combining both approaches maximizes effectiveness.

A well-designed test case suite ensures that Functional Testing (FCT) is both thorough and efficient, uncovering defects that might otherwise go unnoticed.

Automation has become a cornerstone of modern Functional Testing (FCT), enabling faster testing, higher accuracy, and lower labor costs. Key strategies to improve efficiency include:

Automated Test Scripts: Software-driven test sequences reduce human error and ensure consistency across thousands of PCBs.

Data Logging and Analytics: Automated systems can record and analyze large volumes of test data, providing insights into recurring failures and process improvements.

Integration with Manufacturing Execution Systems (MES): Linking FCT automation to MES allows real-time monitoring of production quality and immediate corrective action when failures occur.

Reusability of Test Fixtures: Designing flexible, modular fixtures allows multiple PCB types to be tested with minimal setup changes, reducing cost and downtime.

Continuous Improvement: Regularly reviewing automated test results helps identify inefficiencies, optimize test sequences, and enhance overall FCT performance.

By combining automation with strategic planning and well-designed test cases, manufacturers can achieve both high coverage and efficiency.

One of the most critical roles of Functional Testing (FCT) is the early detection of PCB failures. Detecting defects before a product reaches the customer saves significant costs and safeguards brand reputation. The types of failures FCT can identify include:

Component-Level Failures: Faulty ICs, resistors, capacitors, or connectors that may not meet design specifications.

Circuit-Level Failures: Issues such as open circuits, short circuits, or improper signal routing.

System-Level Failures: Malfunctions that occur only when multiple components interact under operational conditions.

By simulating real-world conditions and verifying system behavior, Functional Testing (FCT) acts as a final checkpoint to catch defects that previous tests (like visual inspection or in-circuit testing) might have missed. Early identification allows engineers to trace the root cause and implement corrective measures, enhancing overall reliability.

Functional Testing (FCT) is not just a quality checkpoint—it is a preventive tool. Consistent implementation of FCT reduces production defects by:

Providing Feedback for Process Improvement: Data collected during FCT reveals recurring defects, which can be addressed in manufacturing processes.

Minimizing Field Failures: Catching defects before products are shipped prevents failures in the hands of end-users.

Enhancing Design Verification: FCT confirms that design assumptions hold true in real operational conditions, which can inform future PCB iterations.

For high-volume production, FCT serves as a safeguard to maintain product quality across multiple batches. Manufacturers can quantify defect rates, compare performance metrics, and implement targeted improvements to both design and assembly processes.

JM PCB, a leading PCB manufacturer, provides a practical example of the benefits of robust Functional Testing (FCT). In their production line:

Each high-density PCB undergoes automated FCT using modular test fixtures tailored to different board types.

Real-world scenarios, including varying loads and temperature ranges, are simulated to evaluate system performance.

Failures are logged, analyzed, and traced to component suppliers or assembly procedures, enabling rapid process adjustments.

Functional Testing (FCT) represents the final line of defense in PCB quality assurance. Beyond identifying defects, it provides actionable insights that improve design, optimize manufacturing processes, and enhance customer trust.

Functional Testing (FCT) represents the final and most critical verification stage in PCB manufacturing. By simulating real-world operational conditions, FCT ensures that every circuit, component, and subsystem on a board performs as intended. Key benefits include:

Comprehensive Quality Assurance: FCT evaluates the PCB as a complete system, detecting latent defects that other tests may overlook.

Enhanced Product Reliability: Early identification of faults reduces the risk of field failures, recalls, and warranty claims.

Process Optimization: Data from FCT provides actionable insights for improving PCB design, assembly, and manufacturing processes.

Customer Confidence: Products that pass rigorous FCT deliver consistent performance, reinforcing brand reputation and trust.

By incorporating FCT into their production workflows, manufacturers ensure that their PCBs meet both design expectations and real-world performance requirements.Functional Testing (FCT) is more than a verification step—it is a strategic tool that bridges design, manufacturing, and quality assurance. By systematically testing PCBs under realistic operational conditions, manufacturers can guarantee product performance, reduce defects, and enhance customer trust.

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering superior surface quality and mechanical strength. It is often preferred for high-frequency PCBs due to its smoother surface, which reduces signal loss.

Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective. While it may have slightly higher surface roughness, it remains suitable for most standard PCB applications. Choosing the right copper foil is critical for both electrical performance and mechanical reliability, and Functional Testing (FCT) can help verify that the selected foil type performs as intended under operational conditions.

Functional Testing (FCT) is typically performed on every production board, especially for high-reliability applications. For prototypes, engineering samples, or low-volume runs, FCT may be applied selectively but should still cover all critical functional paths. Regular FCT ensures that both batch-to-batch consistency and product reliability are maintained.

While Functional Testing (FCT) is highly effective, it does not detect every defect. It primarily identifies functional failures under simulated operational conditions, such as incorrect signal processing, faulty components, or miswired circuits. Some physical or cosmetic defects, like slight solder bridging or surface scratches, may require additional inspections such as AOI (Automated Optical Inspection) or ICT (In-Circuit Testing). Combining FCT with other testing methods maximizes overall coverage.

FCT requires investment in test fixtures, automation, software, and skilled personnel, which can increase initial production costs. However, these costs are offset by the reduction in field failures, warranty claims, and rework. For manufacturers like JM PCB, implementing efficient FCT workflows has proven cost-effective over time by ensuring high reliability and reducing downstream defect-related expenses.

In-Circuit Testing (ICT) evaluates the electrical integrity of individual components and solder connections, focusing on structural and connectivity aspects. Functional Testing (FCT), on the other hand, evaluates the behavior of the entire PCB system under operational conditions. While ICT detects component-level issues, FCT confirms that the board works as intended in real-world scenarios. The two methods are complementary, and together they provide comprehensive quality assurance.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote