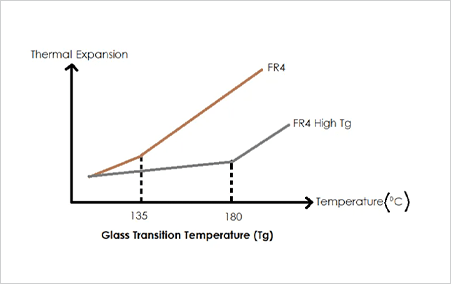

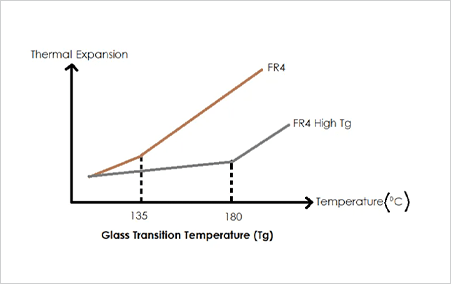

High-Tg PCBs are ideal to use in high-temperature requirements (>170 degree Celsius). Tg

or Glass Transition Temperature defines the temperature limit for the proper working of

PCB.

To put it simply, the working temperature of the PCB should always be less than the

Tg(glass transition temperature) value of the substrate. Tg affects the molecular

weight, crosslinks, and flexibility of the polymer used in the PCB board. High-Tg PCBs

provide better stability and hassle-free operation at a higher temperature.

What happens when the temperature exceeds the Tg value for the PCB?

When the PCB temperature exceeds its Tg value for a considerable amount of

time, the substrate undergoes a change from its glassy state to a rubbery state.So the

substrate doesn’t melt but becomes rubbery and undergoes structural change. With this,

the PCB loses its mechanical and electrical properties.

Properties of High-Tg PCBs

While working on PCBs, the temperature is an important parameter to ensure

reliability. Because as the temperature increases, the materials start expanding, and

hence, their properties change.

So, to ensure that the PCB performs efficiently even at higher temperatures, High-Tg

PCBs are used.

High-Tg materials have the following properties:

1. Lower thermal expansion.

High-Tg PCB undergoes lesser dimension changes at high temperatures. So, when the

temperature lowers down, the chances of cracking or breaking the substrate reduces.

2. Better heat and moisture resistance.

High-Tg PCBs provide better mechanical and chemical resistance than Normal-FR4 PCBs.

Advantages of High-Tg PCBs

Higher Stability

High-Tg PCBs have better heat, chemical, and moisture resistance. It improves the

lifespan of the PCB board by reducing the short circuit and other PCB failures.

Ideal for Multi-layer PCBs

Multi-layer PCBs have complex and dense electronic circuits. With more electronic

components placed in a confined space, the heat generation is way more than standard

PCBs. So, an effective way to tackle this problem is to use substrate made of High-Tg

material.