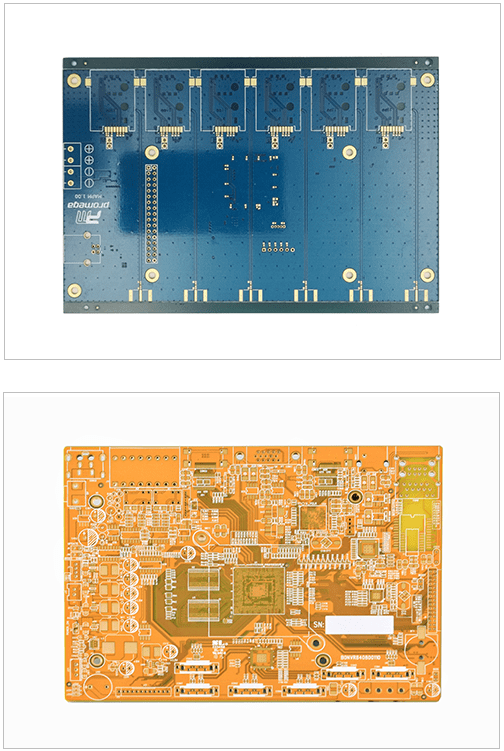

Medical PCB Technologies And Its Type

Extra attention must be taken while producing medical PCBs to assure reliability. This

is because human life relies on the equipment in which they are placed. When it comes to

cleanliness, PCBs must also satisfy very rigorous requirements. This is particularly

true of those utilized in implants. First and foremost, they must be hygienic. They must

also be more compact than usual. As a result, HDI (High-density interconnect) PCBs are

employed in the majority of medical devices.

HDI / via-in-pad technology

The design of inserting the via within the copper pad is known as via-in-pad, and it is

commonly used to save space on the PCB. The PCB may offer up to 50% more space for

component placement when employing in-pad technology. The extensive usage of via in pad

by PCB engineers has resulted from the pursuit of more acceptable pitch devices and

smaller electronic goods.

Surface Mount Technology

Surface mount technology, or SMT, is used in virtually all commercially manufactured

devices today since it provides substantial advantages during PCB manufacturing and

allows considerably more electronics to be packed into a much smaller space due to the

smaller size of SMT components. Aside from the compactness, surface mount technology

(SMT) enables automated soldering and PCB assembly, improving dependability and saving

money.