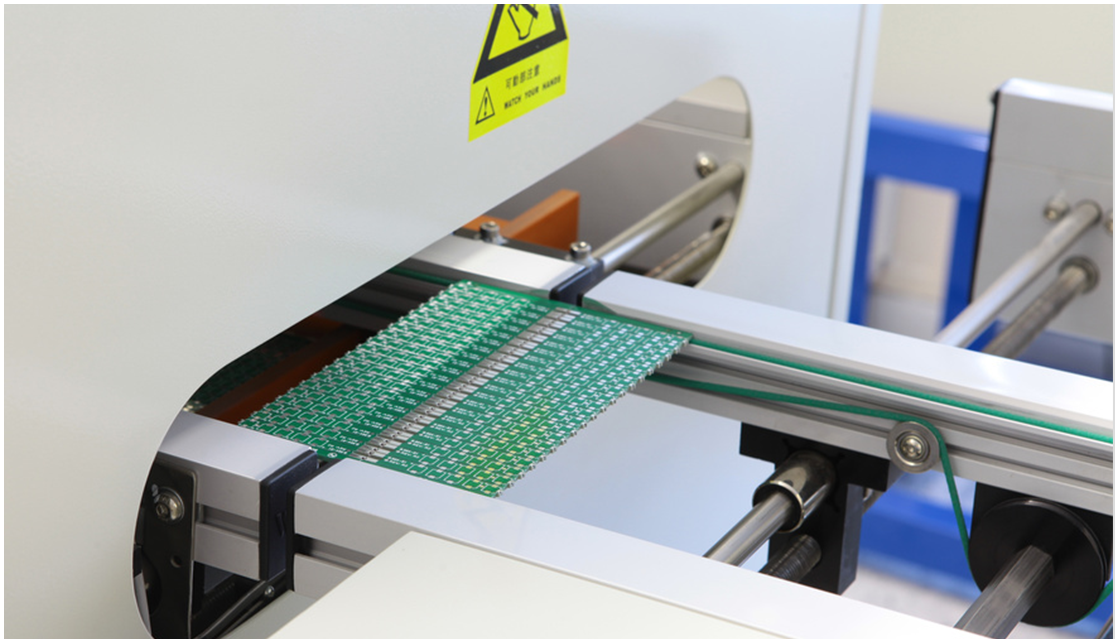

A surface mount technology (SMT) stencil may also be called a PCB stentcil, solder paste

stencil, or laser stencil. An SMT Stencil’s main purpose is to simply transfer the

solder paste to a bare circuit board. A stainless steel foil is laser cut to create an

opening for each surface mount device on the board. Once the printed circuit board (PCB)

stencil is properly aligned with the top of the board, the solder paste is applied over

the openings (in a single pass, with a metal squeegee). When the stainless steel foil

detaches from the board, solder paste remains, ready for the manufacture of the

surface-mount device (SMD). In contrast to manual soldering procedures, this process

ensures consistency and saves time.

The deposited solder paste released to the board is manipulated by opening the size of

the aperture, and the thickness of the SMT stencil is made out of stainless steel.

Excessive paste will cause problems for connectivity and bridging, whereas less paste

will compromise the strength of the soldering and joints.

The thickness of an SMT stencil varies with the device for which it is being used.

0.020” pitch small outline integrated circuits (SOICs) can work better with a stencil

giving a thin solder paste, whereas thick solder paste works best with 0.050” pitch

SOICs. The thickness of the paste stencil for solder ranges from 0.001” to 0.003”. The

normal thickness for most of the PCB boards is generally between 0.004” and 0.007”.

How to clean an SMT Stencil

SMT stencils are generally cleaned with professional cleaning equipment. Presently, the mainstream of the market is the smart stencil cleaning machine, which is aimed at the electronic industry SMT stencil, copper stencil, wire stencil, microporous stencil, and wafer trays. For the cleaning of similar stencils, the equipment uses compressed air as energy, does not require electricity, and is not a fire hazard.

It adopts a human design and one-button operation, which helps complete cleaning and drying tasks; it utilizes high performance automatic operation of air pressure.

Some of the other reasons why you want to partner with them are:

-

Providing a wide range of storage systems and solutions

-

Optimal configuration for your stencil SMT

-

The use of standard and more sophisticated SMT stencil technology

-

Individualized SMT stencil solutions

-

Affordable step stencil design