In PCB production, yield loss rarely announces itself loudly. Instead, it erodes profitability quietly—panel by panel, via by via, defect by defect. Among the many geometric constraints that silently govern yield, Minimum Annular-Ring stands out as one of the most underestimated yet decisive parameters.

From my experience observing both design reviews and factory floors, manufacturers often treat Minimum Annular Ring as a “checkbox rule”—something to meet, not something to control. This mindset is precisely where yield vulnerability begins. In reality, Minimum Annular-Ring is not merely a dimensional requirement; it is a process capability indicator, a reliability buffer, and a cost amplifier when mismanaged.

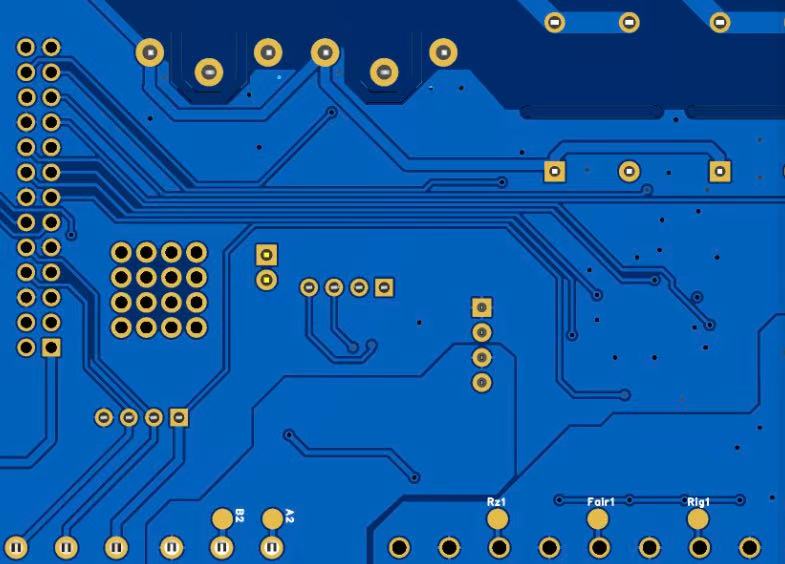

Minimum Annular Ring

At its most basic level, Minimum Annular Ring refers to the minimum radial width of copper remaining around a drilled hole, measured from the edge of the finished hole to the edge of the pad.

However, stopping at this textbook definition is insufficient. In real PCB production environments, Minimum Annular Ring exists at the intersection of:

Drill accuracy

Layer registration

Copper distribution

Imaging precision

Plating uniformity

Each of these variables fluctuates, and Minimum Annular-Ring absorbs their combined error.

From an engineering standpoint, Minimum Annular-Ring functions as a safety margin. It ensures that even when drilling deviates slightly from the pad center, sufficient copper remains to maintain electrical continuity and mechanical anchoring.

Designers often define Minimum Annular-Ring using CAD rules—e.g., 4 mil, 5 mil, or even smaller in HDI layouts. Yet these values frequently assume ideal manufacturing conditions.

A critical insight here is that design-defined Minimum Annular-Ring is aspirational, while manufacturing-achieved Minimum Annular-Ring is statistical.

From the fabrication side, Minimum Annular Ring is not a single number—it is a distribution. Drill wander, material movement during lamination, and copper etch-back all reduce the effective ring width.

Inspection teams evaluate Minimum Annular Ring using AOI, X-ray, or microsection analysis. Importantly, inspection does not improve the ring—it only reveals whether the process was capable enough to preserve it.

Mechanically, Minimum Annular-Ring determines how well a plated through-hole resists:

Thermal expansion stress

Z-axis fatigue

Assembly-induced pad lifting

Electrically, insufficient Minimum Annular-Ring increases the risk of:

Intermittent opens

Barrel-to-pad separation

Increased contact resistance

In high-reliability sectors—automotive, industrial control, and medical electronics—the Minimum Annular Ring often becomes the first line of defense against latent field failures.

Yield loss associated with Minimum Annular-Ring is rarely catastrophic in isolation. Instead, it manifests as:

Incremental scrap rates

Rework loops

Customer return escalations

In mass production, even a 0.5% yield drop linked to marginal Minimum Annular Ring violations can translate into substantial financial impact.

This is why advanced PCB suppliers such as JM PCB invest heavily in drill optimization, stack-up stability, and real-time process monitoring. Their yield-centric philosophy recognizes that controlling Minimum Annular Ring upstream is far cheaper than fixing defects downstream.

Minimum Annular-Ring affects cost through multiple hidden channels:

Scrap and Rework Costs

Marginal rings often fail electrical testing or microsection criteria.

Process Tightening Costs

Tighter rings demand higher-precision drilling and registration systems.

Inspection Overhead

Reduced margins require increased sampling and analysis frequency.

Design Iteration Costs

Late-stage ring violations often force redesigns or panel size changes.

Ironically, attempting to minimize pad sizes aggressively—without accounting for Minimum Annular Ring variability—often increases total cost rather than reducing it.

| Cost Category | Impact of Marginal Annular Ring | Long-Term Effect |

|---|---|---|

| Scrap Rate | Increased failures at AOI/X-ray | Direct material loss |

| Rework | Pad repair and via reinforcement | Labor escalation |

| Inspection | Higher sampling frequency | Longer cycle time |

| Equipment | Need for higher-precision drills | Capital investment |

| Customer Quality | Field returns and complaints | Reputation damage |

Performance impact varies by application:

High-speed digital boards rely on stable via integrity to preserve signal continuity.

Power electronics depend on robust annular rings to manage thermal cycling.

HDI designs push Minimum Annular Ring to its limits, making process capability paramount.

In all cases, Minimum Annular Ring is not a passive geometry—it actively shapes long-term performance outcomes.

Minimum Annular Ring is not just a dimensional check—it is a proxy for overall process health.

When Cp and Cpk values are healthy across drilling, imaging, and plating steps, annular rings remain robust even under tight design rules. When they degrade, Minimum Annular Ring violations are often the first visible symptom.

In practice:

Stable processes produce predictable ring distributions

Unstable processes produce borderline rings that pass today and fail tomorrow

This is why leading PCB manufacturers increasingly integrate annular ring metrics into SPC dashboards rather than treating them as isolated inspection results.

There is an uncomfortable truth in PCB engineering: every micron gained in routing density is borrowed from reliability margin.

Reducing Minimum Annular Ring may:

Increase routing freedom

Lower panel layer count

Improve short-term cost metrics

But it also:

Narrows process windows

Increases inspection burden

Raises long-term failure risk

From a strategic standpoint, manufacturers that consistently protect yield treat Minimum Annular-Ring as a non-negotiable reliability buffer, not a flexible design afterthought.

After examining Minimum Annular Ring from design theory, manufacturing reality, cost structure, and reliability performance, one conclusion becomes unavoidable: annular ring control is not a local optimization—it is a cultural indicator of manufacturing discipline.

In PCB production, yield is rarely destroyed by a single dramatic failure. It is eroded by marginal decisions that shrink safety margins in the name of density, speed, or short-term savings. Minimum Annular Ring sits at the center of these decisions because it quietly absorbs the combined uncertainty of drilling, registration, plating, and material behavior.

What stands out most to me is that Minimum Annular Ring is often discussed late—after layout is frozen, after tooling is ordered, after problems appear. By then, it is no longer a design parameter; it becomes a damage-control exercise. Factories that consistently protect yield do the opposite: they treat annular ring as an early-warning metric, one that reflects whether the entire process chain is aligned or drifting.

Cost analysis further reinforces this point. While tighter rings may appear to reduce material usage or enable compact routing, they frequently introduce hidden expenses through rework, scrap, extended inspection, and customer quality escalations. The most profitable PCB manufacturers are not those who chase minimum values, but those who maintain predictable margins with high statistical confidence.

From a performance and reliability standpoint, Minimum Annular Ring also represents humility in engineering. It acknowledges that no process is perfect and that long-term reliability depends on respecting physical limits rather than testing them. Products fail in the field not because specifications were ignored, but because margins were exhausted.

Ultimately, guarding yield means accepting that small geometric margins carry disproportionate strategic weight. Minimum Annular Ring may be measured in microns, but its influence extends across cost structure, customer trust, and brand reputation. In that sense, controlling it is less about copper geometry—and more about manufacturing philosophy.

By aligning pad sizes with proven factory capability, optimizing stack symmetry, and engaging manufacturers early in the design phase, designers can preserve reliability without excessive area penalties.

Electrical tests verify continuity at a single moment. Minimum Annular Ring determines whether that continuity will survive thermal cycling, vibration, and long-term mechanical stress.

Not necessarily. While tighter rings may reduce pad size and layer count, they often increase scrap, rework, and inspection costs, resulting in higher total manufacturing expense.

Drill positional variation directly consumes annular margin. Even small drill wander can significantly reduce effective copper width, especially in high-density designs.

Yes. HDI structures operate with much smaller margins, making annular ring integrity essential for maintaining via reliability across stacked or staggered interconnects.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote