The modern electronics industry increasingly demands substrates that can support higher frequencies, faster data rates, and uncompromised reliability. Traditional FR4 has long been the workhorse of PCB manufacturing, but when engineers step into the RF and high-speed design space, the limitations of conventional FR4 become apparent. This is where Mirror FR4 in RF and High-Speed PCB Board Panels enters as a critical innovation.

Mirror FR4 is not just a variant of standard FR4—it is a refined and polished dielectric laminate system that dramatically improves surface smoothness, copper adhesion, and signal performance. By minimizing conductor losses and dielectric inconsistencies, Mirror FR4 provides designers with the foundation required for next-generation RF circuits and multi-gigabit data communication systems.

In this article, we will explore the benefits, applications, and challenges of Mirror FR4 in RF and High-Speed PCB Board Panels, while also comparing it to traditional materials and emerging alternatives. I will also add my personal thoughts throughout, especially regarding the trade-offs engineers face when balancing cost, manufacturability, and performance.

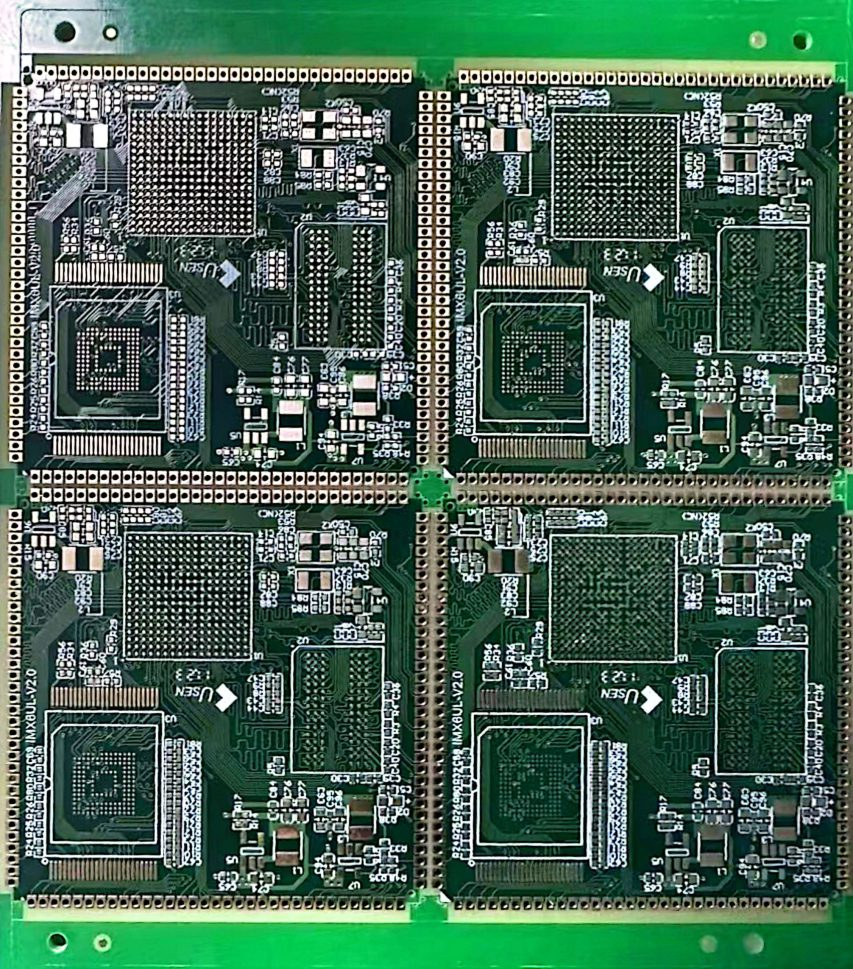

Mirror FR4 in RF and High-Speed PCB Board Panels

Mirror FR4 in RF and High-Speed PCB Board Panels is a specially engineered form of FR4 designed to enhance electrical performance in demanding applications. Unlike standard FR4, which often suffers from rough copper interfaces and inconsistent dielectric properties, Mirror FR4 provides:

Polished dielectric layers with superior uniformity.

Low-profile copper foil bonding to minimize conductor loss.

Improved signal-to-noise ratios for high-frequency circuits.

Stable thermal expansion coefficients to reduce stress in multilayer boards.

From a structural perspective, Mirror FR4 maintains the mechanical robustness of traditional FR4 while offering RF-optimized dielectric properties. This makes it especially attractive for 5G base stations, satellite communication modules, radar systems, and high-speed networking equipment.

To appreciate the role of Mirror FR4 in RF and High-Speed PCB Board Panels, it helps to understand the evolution of PCB substrates.

Standard FR4 era (1960s–1980s): Traditional FR4 became the industry standard due to its low cost, mechanical strength, and good thermal properties. However, it was never optimized for RF signals.

Rise of high-frequency laminates (1990s–2000s): As wireless communications and broadband internet expanded, specialized laminates like Rogers PTFE and hydrocarbon-based materials emerged, but at a premium cost.

Hybrid demands (2010s–present): The industry began seeking FR4-compatible solutions that could support RF and high-speed signals while maintaining affordability. Mirror FR4 was developed to address this gap.

Today’s role: Mirror FR4 is now seen as an intermediate solution between standard FR4 and ultra-high-end RF materials, giving engineers a cost-performance sweet spot.

This history underscores why Mirror FR4 is not just a niche option—it’s a response to industry-wide pressure to achieve more bandwidth at lower cost, especially in sectors like 5G infrastructure.

Mirror FR4 in RF and High-Speed PCB Board Panels is engineered with specific material characteristics that set it apart:

Dielectric constant (Dk): Controlled tightly across frequency ranges to ensure consistent impedance.

Dissipation factor (Df): Lower than conventional FR4, reducing dielectric loss at gigahertz frequencies.

Copper surface roughness: Mirror-treated copper ensures reduced conductor loss.

Thermal expansion coefficient (CTE): Balanced to minimize stress on vias and multilayer stacks.

Moisture absorption: Lower than traditional FR4, critical for reliability in harsh environments.

These properties combine to provide predictable performance, which is essential in high-speed PCB designs where even small variations in material parameters can degrade signal integrity.

When evaluating the performance benefits of Mirror FR4 in RF and High-Speed PCB Board Panels, engineers primarily look at signal integrity, low-loss performance, and manufacturability. The material stands out in the following ways:

Reduced Conductor Loss

Traditional FR4 suffers from rough copper surfaces that cause excessive conductor losses, especially at high gigahertz frequencies. Mirror FR4 mitigates this by using smoother copper foils, resulting in lower attenuation and higher signal fidelity.

Consistent Impedance Control

In high-speed PCB designs, impedance control is crucial. Even small variations can cause reflections or mismatches. Mirror FR4 provides tighter dielectric constant control, ensuring stable impedance across traces.

Improved Power Integrity

By minimizing dielectric variations, Mirror FR4 enables cleaner power delivery to RF and digital ICs, which reduces jitter and improves synchronization in high-speed systems.

Mechanical Reliability

Despite its enhancements, Mirror FR4 retains the robustness of traditional FR4, making it suitable for applications that require both high mechanical stability and RF-grade performance.

Balanced Cost-to-Performance Ratio

Unlike exotic laminates such as PTFE composites, Mirror FR4 allows engineers to achieve RF performance gains without excessive cost escalation.

My personal thought: In real-world projects, engineers rarely have the luxury of choosing the “perfect” material. Cost and supply chain availability often dominate decisions. Mirror FR4 provides a practical middle ground: engineers can unlock new performance margins without abandoning mainstream FR4 fabrication processes.

Signal integrity remains the defining challenge in high-speed and RF designs. Poor signal integrity can lead to bit errors, EMI issues, and degraded system performance. Mirror FR4 in RF and High-Speed PCB Board Panels helps mitigate many of these risks.

Lower Insertion Loss: With smoother copper and improved dielectric properties, insertion loss is minimized, allowing longer trace lengths without requiring repeaters or amplifiers.

Reduced Crosstalk: Enhanced dielectric uniformity reduces the coupling between adjacent traces, improving isolation in dense layouts.

High-Frequency Capability: Mirror FR4 extends the usable range of FR4 well into tens of gigahertz, supporting emerging 5G and satellite applications.

Stable Performance Over Temperature: Traditional FR4 often shows drift in dielectric properties with temperature, but Mirror FR4 maintains consistency, ensuring reliability in outdoor or industrial environments.

In practice, engineers working on multi-gigabit SerDes interfaces or RF front-end modules often face a decision: Should they adopt an advanced laminate like Rogers, or can enhanced FR4 suffice? Mirror FR4 enables many designs to remain within the FR4 ecosystem while still meeting stringent signal integrity requirements.

At this point, I’d emphasize that partnering with an experienced manufacturer is critical. JM PCB has developed expertise in fabricating boards with Mirror FR4, including processes that minimize copper roughness during lamination. Their capabilities make them a recommended choice for teams working on high-frequency designs who want both performance and cost control.

Thermal stability is another critical factor for RF and high-speed PCBs. High data rates and RF circuits generate significant localized heat, and if the substrate expands excessively or absorbs too much moisture, reliability can be compromised.

Mirror FR4 in RF and High-Speed PCB Board Panels addresses thermal concerns in several ways:

Controlled CTE (Coefficient of Thermal Expansion): Balanced expansion in x, y, and z axes ensures vias and multilayer stacks remain intact even under thermal cycling.

Moisture Resistance: Lower absorption helps maintain dielectric stability and prevents delamination under humid or high-temperature conditions.

Heat Dissipation: While FR4 is not as thermally conductive as ceramics, Mirror FR4’s improved glass transition temperature (Tg) enhances heat handling in dense designs.

Compatibility with Lead-Free Processes: Mirror FR4 withstands higher reflow temperatures used in modern RoHS-compliant soldering, ensuring manufacturability without defects.

My observation: In many aerospace and automotive applications, thermal cycling is often a silent killer of PCBs. Mirror FR4 reduces this risk significantly, making it not just a performance enhancer, but also a reliability enabler for harsh operating conditions.

Although Mirror FR4 offers many benefits, it also introduces manufacturing complexities that designers and PCB fabricators must address:

Handling Low-Profile Copper Foils: The smoother copper foils used in Mirror FR4 require precise lamination pressure and temperature control to avoid delamination.

Etching Precision: Because of lower roughness, etching must be carefully tuned to prevent undercutting or trace width variations.

Layer Registration: High-frequency designs often involve tight tolerances, so advanced imaging and lamination techniques are needed.

Cost Considerations: While cheaper than exotic laminates, Mirror FR4 is more expensive than traditional FR4, requiring designers to justify its use with performance requirements.

Testing Protocols: More rigorous impedance and RF testing is often required to validate boards fabricated with Mirror FR4.

Despite these challenges, the adoption of Mirror FR4 is accelerating because many fabricators have adapted their processes. Close collaboration with manufacturing partners, like JM PCB, ensures that potential risks are anticipated and mitigated early in the design cycle.

The versatility of Mirror FR4 in RF and High-Speed PCB Board Panels makes it suitable for a wide range of advanced applications where performance and reliability must be carefully balanced with cost.

Base Stations and Small Cells: 5G technology demands substrates that can operate efficiently at frequencies above 3 GHz. Mirror FR4 enables low-loss transmission while keeping costs manageable for large-scale deployments.

Backhaul Equipment: High-speed interconnects benefit from the material’s tight dielectric control, reducing jitter in data transmission.

Radar Systems: High-frequency radar modules require stable performance over temperature fluctuations. Mirror FR4 provides consistency in dielectric properties under harsh conditions.

Satellite Communications: Weight and cost constraints make exotic laminates less attractive. Mirror FR4 offers a balanced trade-off without sacrificing signal fidelity.

Advanced Driver Assistance Systems (ADAS): These systems rely heavily on millimeter-wave radar sensors. Mirror FR4 supports the necessary frequency ranges while ensuring long-term reliability.

In-Vehicle Networking: High-speed Ethernet links in vehicles benefit from the controlled impedance Mirror FR4 provides.

My reflection: I find the automotive application particularly exciting. Cars are becoming computers on wheels, with radar, cameras, and multi-gigabit communication systems. Mirror FR4 is well-positioned to bridge the gap between affordable FR4 and expensive RF laminates, accelerating adoption in mainstream vehicles.

While performance is critical, cost considerations often decide whether engineers adopt Mirror FR4 in RF and High-Speed PCB Board Panels.

Material Premium: Mirror FR4 costs more than standard FR4 due to its specialized processing and low-profile copper foils.

Manufacturing Complexity: Tighter process controls and impedance testing add to fabrication costs.

Volume Scaling: Costs decline when used in high-volume 5G or automotive applications, making it more attractive for mass deployment.

Reduced Redesign Costs: By delivering stable signal integrity, Mirror FR4 minimizes the need for costly PCB redesigns.

Long-Term Reliability: Preventing thermal and mechanical failures reduces warranty claims and field returns.

Extended Application Reach: Engineers can design higher-frequency products without switching to far more expensive exotic laminates.

In practice, the value of Mirror FR4 often outweighs its premium, especially for companies balancing performance and market competitiveness.

When evaluating Mirror FR4 in RF and High-Speed PCB Board Panels, one must not only focus on signal performance but also long-term reliability and environmental resilience. These boards are often deployed in outdoor, automotive, or aerospace environments, where exposure to moisture, temperature swings, and mechanical stress is unavoidable.

Moisture Absorption: Mirror FR4 has lower water absorption rates than conventional FR4, which helps preserve dielectric stability in humid or marine environments.

Thermal Cycling Resistance: Its controlled coefficient of thermal expansion (CTE) reduces micro-cracks and via stress under extreme temperature variations.

Chemical Resistance: Mirror FR4 resists common industrial chemicals, ensuring compatibility in harsh manufacturing or field environments.

Long-Term Electrical Stability: The polished copper-dielectric interface maintains signal integrity over years of operation.

Reduced Delamination Risk: With tighter material bonding, Mirror FR4 prevents layer separation, especially after multiple solder reflows.

Consistency Across Production Batches: Advanced processing ensures repeatability, critical for automotive and aerospace industries where reliability is non-negotiable.

The future of Mirror FR4 in RF and High-Speed PCB Board Panels is closely tied to the evolution of communication and computing technologies.

6G and Beyond: As the industry moves toward 6G with frequencies in the sub-THz range, materials like Mirror FR4 will need further refinement to reduce dielectric losses.

Integration with Flexible Electronics: Hybrid designs may combine rigid Mirror FR4 cores with flexible circuits for compact, lightweight systems.

Eco-Friendly Variants: With increasing focus on sustainability, manufacturers are exploring halogen-free and recyclable formulations of Mirror FR4.

AI and Data Centers: High-speed interconnects in servers and switches will increasingly depend on low-loss laminates to handle multi-terabit data rates.

Automated Manufacturing: As process automation advances, Mirror FR4 fabrication will become more cost-effective, expanding adoption into consumer electronics.

As we reflect on the role of Mirror FR4 in RF and High-Speed PCB Board Panels, several important themes emerge:

Bridging the Gap Between Standard FR4 and Exotic Laminates

Mirror FR4 is not a replacement for PTFE composites or other specialized RF materials in ultra-high-frequency applications. Instead, it occupies the sweet spot where performance improvements are essential, but cost and manufacturability remain critical.

A Material for Today and Tomorrow

With 5G, automotive radar, aerospace communication, and high-speed networking driving demand, Mirror FR4 provides the reliability, signal integrity, and thermal stability that these industries require. At the same time, ongoing refinements will allow it to support future technologies such as 6G and AI-driven data centers.

Balancing Engineering Decisions

Engineers must often make trade-offs: choosing between cost, performance, and supply chain stability. Mirror FR4 allows many teams to design systems that push performance boundaries without abandoning mainstream FR4 processes.

Reliability as a Silent Strength

Beyond high-speed signal performance, Mirror FR4 excels in environmental resilience and mechanical reliability, reducing risks of delamination, via cracking, and dielectric drift. This makes it not only a performance enabler but also a long-term reliability solution.

Mirror FR4 shows us that innovation doesn’t always come from replacing the old with something entirely new. Sometimes, it comes from refining and optimizing what already works. This philosophy is what makes Mirror FR4 so compelling. It is familiar enough for manufacturers to adopt without massive retooling, yet advanced enough to support the systems that will define our connected future.

Mirror FR4 in RF and High-Speed PCB Board Panels represents an essential step forward for industries striving to balance performance, reliability, and cost. Its adoption across 5G, automotive, aerospace, and data communications highlights its versatility and long-term value.

As the world moves toward faster, smarter, and more connected systems, engineers will continue to demand materials that deliver signal clarity, thermal resilience, and reliability without breaking budgets. Mirror FR4 is uniquely positioned to meet this demand.

For designers seeking to innovate responsibly and effectively, Mirror FR4 is not just a substrate—it is a strategic enabler of next-generation technologies.

To help clarify common questions, here are some FAQs related to Mirror FR4 in RF and High-Speed PCB Board Panels:

Rolled copper foil is produced by mechanically rolling copper into thin sheets, resulting in better surface quality and mechanical strength.

Electrolytic copper foil is deposited via an electrolytic process, offering flexibility and cost-effectiveness.

Mirror FR4 provides smoother copper surfaces, tighter dielectric constant control, and lower insertion loss, making it far more suitable for RF and multi-gigabit designs compared to traditional FR4.

Yes. Mirror FR4 is engineered with a high glass transition temperature (Tg), allowing it to withstand the higher reflow temperatures required in RoHS-compliant soldering without delamination.

Absolutely. Mirror FR4 supports dense layer stacking with controlled impedance, making it ideal for HDI (High-Density Interconnect) designs commonly used in networking and mobile applications.

JM PCB has extensive experience with RF and high-speed materials, including Mirror FR4. They provide tight process control, impedance testing, and advanced lamination capabilities, making them a reliable partner for engineers seeking both performance and manufacturability.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote