Advanced Printed Circuit Board Laminate Materials

We work with top PCB laminate providers to bring you a wide range of material options such as enhanced epoxy laminates, ultra-low moisture materials, high-frequency ceramic filled laminates, UL 94V-0 rated, RoHS compliant, and more. Your choice of laminate material will depend on your design and application. If you need assistance selecting your printed circuit board laminate material and have questions about cost, leadtime, or availability, please contact us.

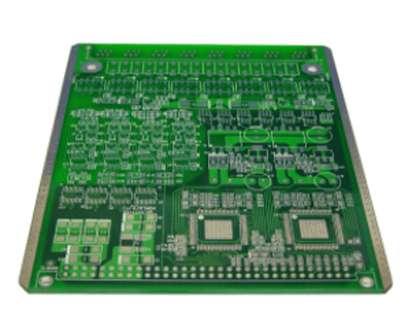

BGA Design proposal

The economical solution for circuit board prototypes with 1, 2, 4, 6, 8 or 10 layers, and a small overall area. Our PCB Calculator always shows the best price and production time.

No minimum quantity, get the renowned Multi-CB quality already from 1 piece.

Our favorable offer for printed circuit board prototypes already includes many high-tech options such as track / annular ring 0.1mm and holes 0.2mm. The standard-production time starts at fast 4 working days (WD) up to 0.05m², 1WD express is possible. Order your boards until 9:00 am, counting the current day as the production day.

Panel production

Our prototype services also offers panel production. We differentiate between simple panels (all the same circuit boards) and complex panels (for different circuit boards).

Pooling

Circuit boards of different customers with identical specifications can be produced in the same production panel. This grouping of similar orders is called pooling. Pooling reduces manufacturing costs and increases flexibility. Our customers take advantage of both benefits.

Why need panel design when manufacturing PCBs?

-

Improving fabrication efficiency

Some PCBs are too small to meet the requirements of SMT fixtures, put them into a large board is more convenient for manufacturing. And the SMT process of multiple PCBs can be run at the same time in automatic machines, then increase the utilization rate of machines.

-

Good quality control

Automated production is conducive to quality control and improves the yield of fabrication.

-

Reducing

PCB assembly cost

Panel design is more suitable for automatic production line, which can save labor costs. And it helps to use the PCB area effectively and reduce materials waste by panel design for some different shaped PCBs.