Choosing the right PCB manufacturing company can determine the success or failure of your electronics project. From design compatibility and pricing to turnaround time and after-sales support, every detail matters. In today’s fast-paced, quality-driven market, OEMs, startups, and hardware developers need manufacturing partners who are not only cost-efficient but also technically reliable. This article explores what PCB manufacturing companies do, how to assess their capabilities, and how to choose the right partner for your project. Whether you’re building a prototype or scaling to mass production, this guide is built for you.

PCB Manufacturing Company

Let’s start from the top: what is a PCB manufacturing company?

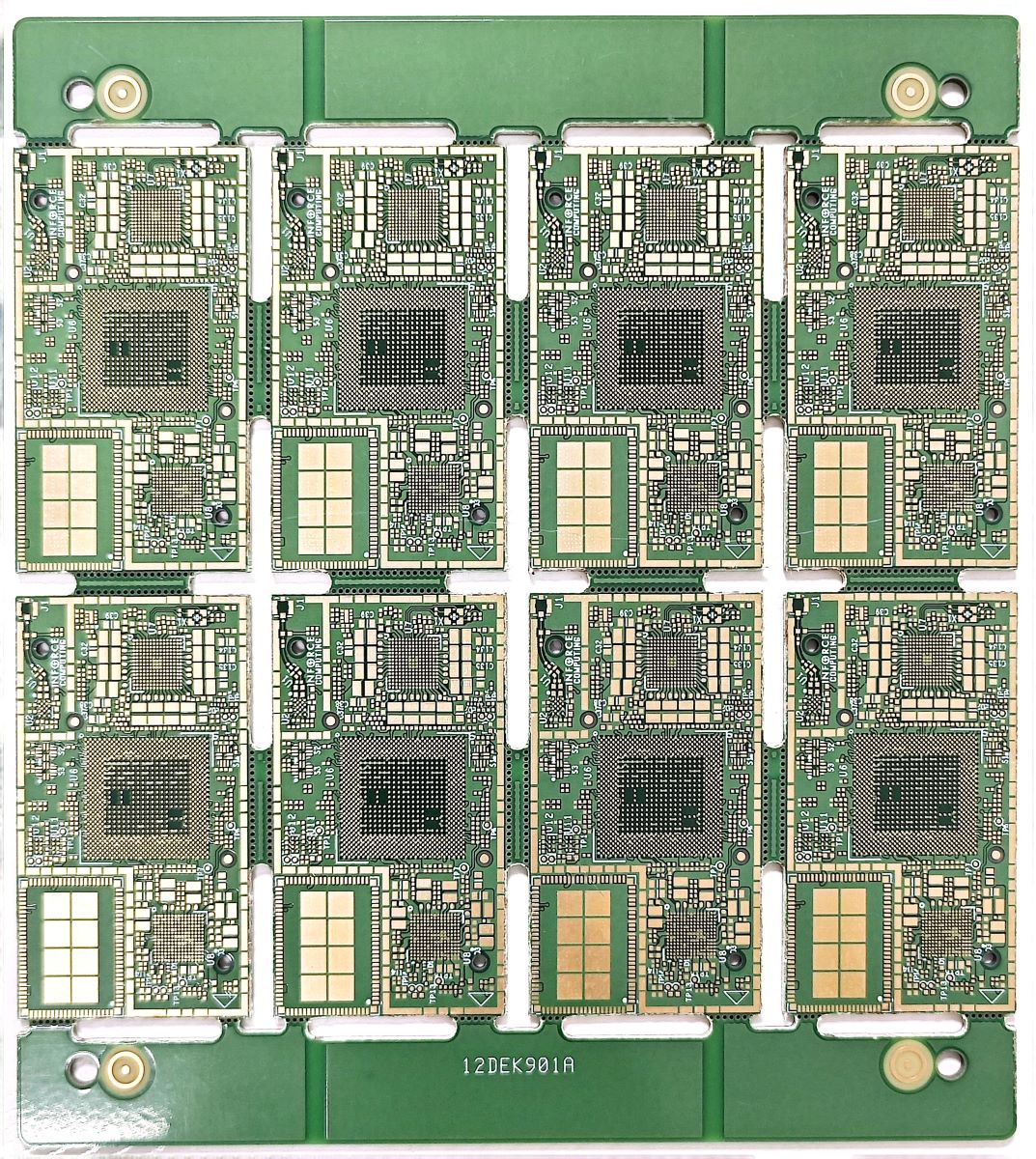

In simple terms, it’s a company that fabricates printed circuit boards (PCBs)—the core of any modern electronic device. These manufacturers convert design files into physical boards using advanced processes like photolithography, etching, plating, solder masking, and electrical testing.

But here’s the kicker… Not all PCB manufacturers are created equal. Some specialize in prototyping; others focus on bulk production. Some are experts in flex and rigid-flex; others deal strictly in rigid FR4.

Globally, PCB manufacturers are clustered in regions like China, Taiwan, Germany, and the United States. While Asia offers aggressive pricing and scale, Western companies often prioritize quality, traceability, and design collaboration.

| Region | Strengths | Considerations |

|---|---|---|

| China | Low cost, high volume | Communication & IP risk |

| USA | Quality & service | Higher cost |

| Germany | Precision & engineering | Longer lead times |

| India | Competitive pricing | Emerging quality standards |

Knowing the landscape sets the foundation for making informed decisions. Jerico Multilayer PCB provides high-quality, reliable solutions for businesses looking to source PCBs, ensuring the right balance of cost and performance for various industries.

When evaluating a PCB supplier, understanding their specialization is essential.

First, you have bare board manufacturers. These companies only fabricate the physical PCB, stopping short of component assembly. Perfect for prototyping or clients who do in-house SMT.

Then come PCB assembly providers. These firms handle both fabrication and assembly—sourcing components, placing them, soldering, and testing the final boards.

And finally, turnkey manufacturers offer an end-to-end solution. From design support to procurement, from fabrication to boxed delivery—they manage every step.

But here’s the real story… choosing the wrong type of manufacturer can cost you delays, rework, and missed market windows.

| Manufacturer Type | Core Services | Best For |

|---|---|---|

| Bare Board | Fabrication only | R&D teams, lab testing |

| Assembly Only | SMT/THT mounting | Clients with custom boards |

| Turnkey | All-inclusive | Startups, scalable products |

Align your needs with the provider’s capabilities for smooth collaboration.

This debate never gets old. Should you partner with a local manufacturer or go overseas?

Domestic manufacturers offer better communication, faster shipping, and easier quality control. However, you’ll often pay more. Overseas—especially in China or India—you can save significantly, but you may face longer lead times, cultural differences, or concerns about intellectual property.

Ready for the good part? Many companies now use hybrid sourcing: prototyping locally and scaling overseas.

| Factor | Domestic | Overseas |

|---|---|---|

| Cost | Higher | Lower |

| Communication | Easier | May require adaptation |

| Turnaround Time | Faster | Slower |

| Customization | Higher | May be limited |

| Risk | Lower | Higher (for new vendors) |

If cost is king and your design is mature, go overseas. If design changes or urgent delivery are likely, stay local—or at least regional.

What separates a good PCB manufacturer from a great one? Certifications.

But here’s the real story… certifications aren’t just for show. They confirm that your partner follows internationally accepted manufacturing, quality, and environmental protocols.

Look for these essential ones:

● ISO 9001 – Quality management system

● UL – Product safety certification (especially in the U.S.)

● RoHS – Restriction of hazardous substances

● IPC-A-600/IPC-A-610 – Visual quality standards for PCBs and assemblies

| Certification | What It Covers | Importance |

|---|---|---|

| ISO 9001 | Quality systems | High |

| UL | Electrical safety | Mandatory for U.S. |

| RoHS | Hazardous materials | Mandatory in EU |

| IPC-A-600 | Bare board standards | Visual & process quality |

| ISO 13485 | Medical device quality | Required for medical PCBs |

Don’t just take their word—ask for digital certificates or audit summaries.

Capabilities define compatibility.

If your design includes 0.1 mm traces, via-in-pad, or RF routing, you need a manufacturer who can handle it without pushing back or charging excessively.

Let’s break this down.

● Minimum trace/spacing – Critical for HDI designs

● Copper weight – Essential for power electronics

● Material compatibility – FR4, polyimide, Rogers, aluminum

| Capability | Industry Benchmark | What It Affects |

|---|---|---|

| Trace/Spacing | 3/3 mil | Signal integrity |

| Min Hole | 0.2 mm | Via density |

| Layer Count | Up to 40 layers | Complex circuits |

| Impedance Control | ±10% | High-speed signals |

Choosing a company that understands your design’s nuances reduces DFM (Design for Manufacturability) issues and improves first-pass yield.

This is where it gets interesting…

Modern PCB manufacturing companies aren’t just stamping copper on substrates—they’re pushing innovation boundaries to match the needs of high-speed, miniaturized, and energy-efficient devices.

Let’s dive into key trends:

● High-Density Interconnect (HDI) – Essential for smartphones, tablets, and compact wearables

● Flexible & Rigid-Flex Boards – Used in medical, aerospace, and military tech

● Embedded Components – Improves signal integrity and board space

● Heavy Copper PCBs – Ideal for power applications and automotive

And guess what? Smart factories with AI-driven process monitoring and Industry 4.0 integration are also becoming more common.

| Technology | Use Case | Value Added |

|---|---|---|

| HDI | Mobile, IoT | Space-saving, high-speed |

| Rigid-Flex | Aerospace, Defense | Durability, flexibility |

| Embedded Passives | RF, Telecom | Reduced EMI |

| 3D Printing | Prototyping | Faster iteration |

Work with a manufacturer who stays on the edge of technology, not one stuck in 2005.

Choosing the right material is just as critical as layout.

Here’s the kicker… using a cheap or incompatible base material can lead to delamination, signal loss, or overheating.

PCB manufacturing companies work with a range of materials depending on application:

● FR-4 – The most common glass-epoxy substrate

● Rogers/RF Material – Low-loss, high-frequency boards

● Aluminum/Metal Core – For LED and power PCBs

● Polyimide – Heat-resistant and flexible

| Material | Property | Ideal For |

|---|---|---|

| FR-4 | Cost-effective, stable | General electronics |

| Rogers 4350 | Low dielectric loss | RF/microwave |

| Aluminum | High thermal conductivity | LED lighting |

| Polyimide | Flexibility & heat resistance | Wearables, aerospace |

The best manufacturers will recommend material substitutions that save cost without sacrificing function.

Prototyping is more than just a warm-up round—it’s the moment of truth for your design.

So what’s the real story? A capable express PCB manufacturing company will offer fast, accurate, and feedback-driven prototyping services that improve your final product.

Here’s what good prototyping service should include:

● Quick-turn fabrication – 24–72 hours delivery

● DFM feedback – Prevent costly mass-production issues

● Options for multiple iterations – Test variations side-by-side

● Comprehensive testing – AOI, flying probe, X-ray inspection

| Feature | Benchmark | Impact |

|---|---|---|

| Lead Time | 1–3 days | Time to market |

| Min Order Qty | 1–10 pieces | R&D affordability |

| Test Methods | AOI, electrical, X-ray | Fault detection |

| DFM Report | Automated + manual | Design validation |

If they don’t offer real-time quoting and feedback, you’re likely wasting time.

Ready for the good part?

Scaling from 10 units to 10,000 is where PCB manufacturing companies either shine—or crash and burn.

Look for companies that offer:

● Panel optimization – Maximize material usage

● Staggered volume pricing – Cost drops as quantity increases

● Process automation – Reduces defect rates and labor costs

● Flexible logistics – Air, sea, and DDP options

| Scaling Feature | What It Does | Why It Matters |

|---|---|---|

| Panel Utilization | Reduces waste | Lowers cost |

| Automated AOI/SPI | Catch defects early | Boosts yield |

| Flexible MOQs | Scales with your growth | Budget friendly |

| Packaging Options | Prevents damage | Improves delivery success |

A great prototype isn’t enough—you need a partner who can carry the load when it gets real.

Mistakes happen—but choosing the wrong manufacturing partner can be catastrophic.

Here’s what to watch for:

● Focusing only on price – Low cost can mean low quality

● Ignoring DFM capability – Without it, you risk production issues

● Not vetting certifications – Uncertified shops often cut corners

● Poor communication – Misunderstandings cost time and money

● Not testing samples – First article inspection is non-negotiable

| Mistake | Risk | Prevention Tip |

|---|---|---|

| Chasing lowest quote | Quality problems | Balance cost vs. capability |

| Skipping sample run | Mass defects | Always do pilot test |

| Ignoring logistics | Delays or loss | Choose DDP shipping |

| No NDA/IP agreement | Risk of IP theft | Always sign contracts |

Take your time to vet partners—it’s cheaper than fixing thousands of bad boards.

But here’s the kicker…

Not all PCB manufacturing companies are created equal. Certifications act as a stamp of credibility—proof that your partner adheres to global quality and safety benchmarks.

Essential certifications include:

● ISO 9001 – General quality management

● UL Certification – Flame-retardant standards for North America

● RoHS Compliance – Environmental standards on hazardous materials

● IATF 16949 – Required for automotive applications

● AS9100 – For aerospace-grade boards

| Certification | Industry | What It Ensures |

|---|---|---|

| ISO 9001 | General | Consistent processes and quality |

| UL | North American Market | Electrical safety and fire resistance |

| RoHS | EU and global | Toxic substance control |

| IATF 16949 | Automotive | Traceability, reliability |

| AS9100 | Aerospace | Flight-worthy reliability |

If a PCB manufacturer lacks these, it’s a red flag. Keep walking.

Ready for a strategic decision?

You’ll need to choose between local convenience and global pricing power. Let’s weigh the pros and cons.

Local manufacturers offer:

● Faster shipping

● Easier communication

● On-site visits possible

But they often charge more due to labor and operational costs.

Global manufacturers, especially in Asia, offer:

● Lower prices for mass production

● Advanced technical expertise

● Larger-scale capabilities

| Factor | Local | Global |

|---|---|---|

| Cost | Higher | Lower |

| Speed | Faster (for small runs) | Depends on logistics |

| Tech Capabilities | Moderate | High |

| MOQ Flexibility | Less | More |

| Support | In-person possible | Remote via platform |

The best strategy? Combine both—prototype locally, scale globally.

This is where it gets interesting…

Even the most high-tech PCB manufacturing company will disappoint if communication is poor.

Excellent customer support includes:

● Dedicated account managers

● Fast and clear quotation processes

● Multilingual support

● Transparent production tracking

| Support Feature | What It Means | Why You Need It |

|---|---|---|

| 24/7 Response | Global timezone coverage | No waiting games |

| Quotation Accuracy | Detailed, prompt quotes | Prevent surprise costs |

| Issue Resolution | Fast fixes for defects | Avoid delays |

| Order Tracking | Real-time updates | Better planning |

The right manufacturer will feel like an extension of your team—not just a vendor.

What’s the real story?

Environmental responsibility isn’t just a buzzword—it’s fast becoming a requirement. Customers and governments alike are watching.

Top PCB manufacturing companies are adopting sustainable practices such as:

● Lead-free soldering (RoHS)

● Recyclable materials and packaging

● Water-based surface treatments

● Energy-efficient machinery

| Practice | Benefit | Compliance |

|---|---|---|

| RoHS Materials | Safer, greener boards | EU compliance |

| Wastewater Treatment | Protects ecosystems | Local regulations |

| Cleanroom Facilities | Reduces emissions | Higher yields |

| Smart Energy Systems | Cuts carbon footprint | ESG standards |

Make sure your manufacturer is not only green-washed—but truly green-minded.

Let’s bring it all together.

Finding the right PCB manufacturing company is about balancing cost, quality, scalability, and communication. Don’t go into it blind.

Here’s a step-by-step checklist to guide your decision:

● Define your technical needs clearly

● Ask for sample runs and DFM reports

● Evaluate certifications and past projects

● Compare quotations side by side

● Talk to support—see how responsive they are

| Step | Action | Outcome |

|---|---|---|

| 1 | Submit detailed RFQ | Accurate pricing |

| 2 | Review sample quality | Validate capability |

| 3 | Check certifications | Confirm standards compliance |

| 4 | Visit or video tour | Build trust |

| 5 | Start with small order | Reduce risk |

The right partner won’t just fulfill your specs—they’ll empower your growth.

Choosing the right PCB manufacturing company is a cornerstone decision for your business. From capabilities and certifications to pricing models, prototyping, and sustainability—it all matters.

The best manufacturers aren’t just board suppliers; they’re technical collaborators invested in your success.

Jerico Multilayer PCB offers expert PCB manufacturing solutions with cutting-edge technology and quality control. Whether you need small batches for prototyping or large-scale production, we are the partner you can rely on.

Q1: What is a PCB manufacturing company?

A PCB manufacturing company specializes in producing printed circuit boards, which are the foundation of most electronic devices. These companies handle everything from design verification and prototyping to full-scale production.

Q2: How does PCB manufacturing work?

PCB manufacturing includes multiple stages: design and layout, material selection, layering, etching, drilling, plating, solder mask application, and testing. Each step requires precision machinery and process controls.

Q3: What should I look for in a PCB manufacturing partner?

Key factors include certifications, technical capabilities, turnaround time, communication, pricing transparency, and DFM (Design for Manufacturability) support.

Q4: How do I compare PCB manufacturing quotes?

Compare based on more than just cost—evaluate turnaround time, material types, board complexity, shipping, and included testing. Always request a detailed breakdown.

Q5: Are offshore PCB manufacturing companies reliable?

Yes, many offshore manufacturers in China, India, and Southeast Asia offer excellent quality and competitive pricing. Vet them for certifications, communication, and sample quality before full-scale production.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote