Reliability has become the cornerstone of modern electronics manufacturing. From medical diagnostic equipment to high-speed networking hardware, the expectation for consistent performance under demanding conditions has never been higher. In this environment, printed circuit boards (PCBs) must meet not only electrical performance targets but also mechanical, thermal, and long-term durability requirements. Over the past decade, one of the most significant innovations contributing to these demands is the PCB Resin Plug Hole manufacturing process.

In essence, the PCB Resin Plug Hole technique allows for a more secure and stable way to fill vias, microvias, and through-holes with resin, preventing contamination, improving solder mask adhesion, and enhancing reliability during assembly. This article explores the details of the process, its advantages, and how it strengthens PCB performance across industries. Throughout, I will also integrate my own observations from years of studying manufacturing trends and best practices.

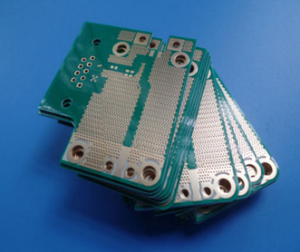

PCB Resin Plug Hole

The PCB Resin Plug Hole method refers to the practice of filling drilled holes or vias in a PCB with a specially formulated resin material. Traditional PCB designs often leave vias open, which can lead to trapped solder during assembly, moisture ingress, or reliability problems during thermal cycling. Resin plugging resolves these challenges by sealing and reinforcing the hole, creating a more consistent and robust substrate.

A PCB Resin Plug Hole typically involves:

Drilling: Microvias, blind vias, or through-holes are drilled according to the PCB design.

Cleaning and Desmearing: Ensuring hole walls are clean for proper resin adhesion.

Resin Application: Applying a carefully controlled epoxy or resin to fill the via.

Curing: The board is heated to polymerize the resin, ensuring a stable fill.

Planarization: Excess resin is removed, and the surface is leveled for further processing.

This process allows designers to:

Avoid short circuits or contamination during soldering.

Support higher component density by enabling via-in-pad designs.

Improve the mechanical strength of the board at stress points.

From my perspective, the PCB Resin Plug Hole approach represents an elegant solution to a long-standing bottleneck in PCB production. In the past, designers had to choose between higher density and reliability; now they can achieve both.

Before manufacturing begins, engineers determine which vias require plugging and what resin properties are most appropriate. Epoxies with controlled thermal expansion coefficients, low moisture absorption, and high mechanical strength are preferred. The selection of resin is critical because it affects not only the plug integrity but also the board’s ability to withstand multiple reflow cycles.

Drilling precision influences how well the resin fills the hole. High-speed drilling equipment with minimal runout ensures consistent via diameters. After drilling, desmearing and cleaning remove debris and residues. This stage also improves adhesion between the resin and the copper walls.

This is where the PCB Resin Plug Hole process truly differentiates itself from standard PCB fabrication. Using screen printing, vacuum-assisted filling, or pressure filling systems, resin is deposited into the via holes. The goal is a void-free fill. Voids can compromise electrical performance or allow moisture to migrate, so quality control at this stage is vital.

Once filled, boards undergo thermal curing. The resin polymerizes and hardens, creating a mechanically robust fill. Excess resin is then removed by planarization to produce a smooth surface ready for solder mask or plating.

The key challenge in the PCB Resin Plug Hole manufacturing process is balancing throughput with quality. Overfilling or underfilling can lead to defects. Automated inspection systems, such as X-ray analysis or microsectioning, are increasingly used to ensure void-free fills and consistent resin distribution.

One of the main benefits of PCB Resin Plug Hole technology is its impact on stability and reliability. By sealing vias, the board resists moisture ingress, reduces outgassing during reflow, and mitigates the risk of solder wicking. Additionally, resin plugs provide mechanical reinforcement in high-stress areas, which is particularly important for boards that undergo flexing, vibration, or temperature cycling.

From a reliability engineering standpoint, resin-plugged vias act almost like rivets within the board structure. This reinforcement reduces the risk of cracking and enhances the mechanical bond between layers. This is why critical applications — from aerospace control modules to 5G base stations — increasingly rely on PCB Resin Plug Hole processes.

Choosing the correct materials for a PCB Resin Plug Hole process is critical to ensuring stability and reliability. The resin acts not only as a filler but as a structural component embedded in the board. Therefore, its properties directly influence the board’s thermal and mechanical performance.

Typical resins for the PCB Resin Plug Hole process are based on advanced epoxies or modified polyimides. They’re formulated to:

Match or closely approximate the coefficient of thermal expansion (CTE) of copper and FR-4.

Withstand multiple lead-free solder reflow cycles at 260 °C without softening.

Exhibit low moisture absorption to prevent delamination or outgassing.

Provide high bond strength to copper-plated hole walls.

By aligning resin properties with board material properties, manufacturers can minimize stresses during temperature fluctuations. This is particularly important in high-density designs with many via-in-pad features.

An often-overlooked aspect is how well the resin interacts with copper plating. If adhesion is poor, the plug may debond, leading to reliability problems. Selecting resins designed for compatibility with electroless or electrolytic copper finishes mitigates these risks.

From my experience, successful PCB Resin Plug Hole production often hinges more on material consistency than on equipment sophistication. Even the best filling equipment cannot compensate for a resin batch with inconsistent viscosity or poor curing behavior. Manufacturers who implement strict incoming material inspections consistently outperform their peers in reliability tests.

Once materials and processes are set, quality assurance (QA) becomes the gatekeeper of reliability. Without rigorous testing, small defects in resin plugs can lead to catastrophic failures in the field.

AOI (Automated Optical Inspection) detects surface defects such as incomplete planarization or resin overflow.

X-ray inspection identifies voids or incomplete fills within vias.

Cross-section analysis provides a microscopic view of the resin-to-copper interface.

By deploying multiple inspection layers, manufacturers can ensure near-zero defect rates.

Boards using the PCB Resin Plug Hole process undergo repeated thermal cycling to mimic real-world conditions. Flexural and peel strength tests measure how the board behaves under stress. Failures are tracked back to process variables, improving subsequent batches.

Statistical Process Control (SPC) methods monitor resin viscosity, fill pressure, and curing profiles. Data-driven process control is the most effective way to maintain consistency at scale.

While the PCB Resin Plug Hole process brings performance gains, it also has cost and environmental implications.

Resin plugging adds process steps — filling, curing, and planarization — which increase production time and cost. However, these costs are offset by:

Reduced assembly defects.

Longer product lifespan.

Less warranty return due to field failures.

Modern resins are formulated to be RoHS-compliant and free of harmful substances. Waste resin and cleaning agents are managed under stringent regulations. Manufacturers that invest in closed-loop systems minimize environmental impact.

From my standpoint, the future of PCB Resin Plug Hole sustainability lies in UV-curable or low-energy-cure resins, which can reduce both curing time and carbon footprint.

The PCB Resin Plug Hole manufacturing process stands as a cornerstone of modern PCB reliability. By sealing vias with high-performance resin, manufacturers achieve:

Enhanced mechanical and thermal stability.

Reduced soldering defects during assembly.

Greater support for high-density and high-frequency designs.

Longer product lifecycles in harsh environments.

This process requires careful material selection, tight process control, and rigorous testing — all areas where suppliers like JM PCB have demonstrated leadership.

Reliability in electronics is no longer optional; it’s a differentiator. As devices become more complex and lifecycles longer, the PCB Resin Plug Hole approach will become the industry standard rather than an advanced feature. I believe the future holds even more refined materials, better simulation tools for designers, and fully integrated production lines that blend mechanical, thermal, and electrical considerations seamlessly.

Ultimately, PCB Resin Plug Hole technology represents more than a manufacturing step — it’s a philosophy of ensuring that every via, every connection, and every layer contributes to a board’s integrity. By adopting and refining this process today, we pave the way for more reliable, efficient, and innovative electronics tomorrow.

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

Via-in-pad designs place vias directly under components such as BGAs. If left open, these vias can trap solder or cause shorts. The PCB Resin Plug Hole process seals and reinforces the vias, ensuring flatness, solderability, and mechanical stability.

Open vias act as pathways for moisture ingress. Filling them with resin creates a barrier against humidity, reducing the risk of delamination, corrosion, and electrical leakage — all critical for high-reliability applications.

Yes, but with constraints. Flexible substrates require resins with lower modulus and higher flexibility. Process parameters must be adjusted to prevent cracking during bending.

Manufacturers use X-ray imaging to detect internal voids, cross-sectioning for microscopic analysis, and automated optical inspection for surface uniformity. Combining these ensures a reliable and consistent fill.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote