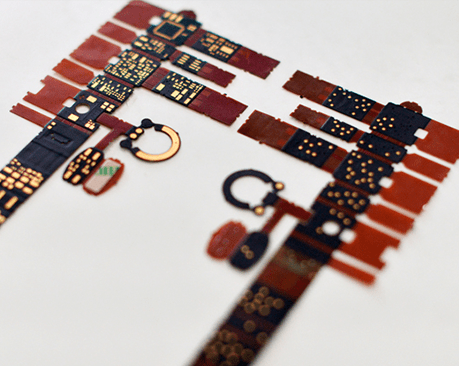

Rigid Flex PCB Technology and Production Process

Whether producing a rigid flex prototype or production quantities requiring large

scale PCB fabrication and PCB assembly, the technology is well proven and reliable.

The flex PCB portion is particularly good in overcoming space and weight issues with

spatial degrees of freedom.

Careful consideration of flex-rigid solutions and a proper assessment of the

available options at the early stages in the PCB design phase will return

significant benefits. It is critical the PCB fabricator is involved early in the

design process to ensure the design and fab portions are both in coordination and to

account for final product variations.

The manufacturing phase is also more complex and time consuming than rigid board

fabrication. All the flexible components of the rigid flex assembly have completely

different handling, etching and soldering processes than rigid FR4 boards.

Benefits of Rigid Flex PCBs

Space requirements can be minimized by applying 3D

By removing the need for connectors and cables between the individual rigid parts

the board size and overall system weight can be reduced.

By maximizing space, there is often a lower count in parts.

Less solder joints assure higher connection reliability.

Handling during assembly is easier in comparison with flexible boards.

Simplified PCB assembly processes.

Integrated ZIF contacts provide simple modular interfaces to the system

environment.

Test conditions are simplified. A complete test prior to installation becomes

possible.

Logistical and assembly costs are significantly reduced with flex-rigid boards.

It is possible to increase the complexity of mechanical designs, which also improves

the degree of freedom for optimized housing solutions.