In the rapidly evolving world of high-frequency electronics, the choice of base material can make or break a product’s performance. Advanced laminates are no longer niche; they are a strategic cornerstone for any company that wants to deliver cutting-edge wireless communications, radar, automotive sensing, and even quantum computing solutions. Among these advanced substrates, Rogers 5870 Material stands out as one of the most trusted and widely deployed PTFE-based composites.

This article, “Unlocking Potential: An Analysis of Future Market Opportunities for Rogers 5870 Material,” offers a comprehensive, 360-degree view of this remarkable material. We will examine its composition, key properties, and advantages. We’ll also explore its cost factors, manufacturing challenges, and the many market sectors where it is poised to grow. Drawing on industry data, case studies, and my own reflections on market trends, this piece will serve as a strategic guide for engineers, product managers, and executives alike.

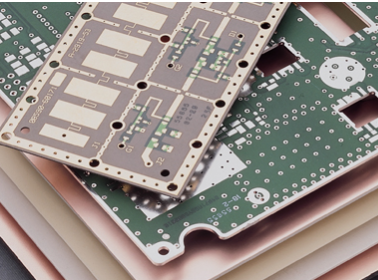

Rogers 5870 Material

Rogers 5870 Material is part of Rogers Corporation’s celebrated RT/duroid® line. It is engineered to deliver a dielectric constant (Dk) of approximately 2.33 and an extremely low dissipation factor (Df) of about 0.0012 at 10 GHz. Its base composition is PTFE reinforced with microglass fibers, which drastically improves its mechanical stability compared to pure PTFE.

Expanding on its core properties:

Dielectric Constant Stability: The 2.33 Dk is remarkably stable over temperature, frequency, and humidity, giving engineers predictable impedance control in high-speed or RF designs.

Ultra-Low Loss Tangent: A Df of 0.0012 minimizes insertion loss, which is vital for millimeter-wave antennas, filters, and couplers.

Moisture Resistance: With moisture absorption below 0.02%, Rogers 5870 Material retains its properties even in tropical or maritime environments.

Thermal Performance: It has a low coefficient of thermal expansion (CTE) in the plane of the board, improving registration for fine-pitch features.

Mechanical Strength: The microglass reinforcement improves drillability, dimensional stability, and copper adhesion during etching and plating.

In practice, these characteristics mean fewer tuning steps, reduced manufacturing variability, and more predictable end-product performance.

In high-frequency design, small deviations in dielectric constant can shift impedance and ruin signal integrity. Low Df reduces energy loss, which directly impacts range, efficiency, and heat generation. Moisture absorption can otherwise cause impedance drift, corrosion, and delamination. Rogers 5870 Material tackles all of these risk points in one unified material.

When evaluating PCB materials, engineers balance four factors: electrical performance, mechanical performance, manufacturability, and cost. Rogers 5870 Material scores strongly on all four, but its biggest differentiator is its combination of high-end electrical performance and mainstream manufacturability.

Key Advantages Expanded:

Superior Signal Integrity:

By keeping dielectric losses extremely low, Rogers 5870 Material allows designers to extend trace lengths, reduce amplification stages, or tighten filter roll-offs without excessive signal degradation. This directly reduces BOM cost and power consumption in RF front ends.

Predictable Impedance Control:

The stable Dk means your 50-ohm or 75-ohm lines stay where you designed them. In mixed-signal environments, this predictability prevents crosstalk and improves EMC compliance.

High Reliability in Harsh Environments:

Its microglass reinforcement and moisture resistance mean fewer field failures. Automotive radar sensors mounted behind bumpers, satellite transceivers exposed to radiation and vacuum, and naval radar systems operating in salt-laden air all benefit from these properties.

Compatibility with Existing Processes:

Unlike some exotic laminates that require entirely new equipment, Rogers 5870 Material can be drilled, plated, and etched using well-established PCB processes. This lowers barriers to adoption and accelerates time-to-market.

Design Flexibility:

It supports multilayer constructions, hybrid stackups, and advanced features like embedded passives or microvias.

Cost Factors Expanded:

Material Price: Rogers 5870 Material carries a premium per square foot compared to FR-4 or mid-tier laminates.

Yield Savings: However, its predictable properties reduce scrap, rework, and tuning, often offsetting the initial premium.

System-Level Savings: Lower loss allows designers to use fewer or smaller amplifiers, reducing total system power consumption and cost.

Longer Lifecycle: High reliability means lower warranty costs and extended product life, which is especially valuable in telecom infrastructure and aerospace.

Because of these factors, many OEMs see Rogers 5870 Material as cost-neutral or even cost-positive over the lifecycle of their products.

Antenna Arrays and Beamforming Networks

At the heart of 5G base stations and satellite ground terminals are complex antenna arrays. Rogers 5870 Material enables tightly controlled feed networks and phase shifters. Lower dielectric loss yields improved efficiency and gain.

RF Couplers, Filters, and Power Dividers

Microwave filters demand sharp roll-off and minimal insertion loss. Rogers 5870 Material’s consistent dielectric properties enable predictable performance across entire production runs.

High-Speed Digital Links

Beyond RF, Rogers 5870 Material also shines in high-speed digital backplanes running at 28 Gbps or higher. Reduced dielectric loss preserves eye diagrams, while low skew improves timing margins.

Test and Measurement Equipment

Oscilloscopes, network analyzers, and signal generators all benefit from the stability and low loss of Rogers 5870 Material, giving instrument makers a competitive edge.

Mixed-Material Stackups

Many designers are adopting hybrid boards: critical RF layers in Rogers 5870 Material, control or power layers in FR-4. This combination balances performance and cost.

The transition to 5G and eventually 6G fundamentally changes the requirements for PCB substrates.

Millimeter-Wave Frequencies

Operating at 24 GHz, 28 GHz, and beyond demands ultra-low-loss substrates. Rogers 5870 Material’s Df of 0.0012 is far below FR-4, reducing insertion loss and improving link budgets.

Antenna-in-Package and Integrated RF Front Ends

As RF front ends become integrated with antennas on the same substrate, thermal and mechanical stability become critical. Rogers 5870 Material’s microglass reinforcement maintains planarity and prevents warping during reflow.

Massive MIMO and Beamforming

Massive MIMO systems with hundreds of antenna elements require precise phase control. Rogers 5870 Material’s tight Dk tolerance enables such precision across large boards.

Scaling to Volume Production

Because Rogers 5870 Material can be processed with standard PCB equipment, ramping from prototypes to full production is more straightforward than with some exotic laminates.

Advanced manufacturing technologies such as additive manufacturing, precision milling, and hybrid lamination are poised to redefine how Rogers 5870 Material can be processed. By integrating computer-aided design with ultra-fine feature production, fabricators can achieve repeatable tolerances and reduced waste. My own view is that as fabrication houses learn to optimize dielectric handling, Rogers 5870 Material will be at the forefront of ultra-reliable high-frequency applications. This trend may also influence the cost curves: although upfront equipment investments are high, longer-term yields improve, lowering per-unit costs.

A second factor is digital-twin modeling. By simulating Rogers 5870 Material performance under different RF loads or thermal stresses, engineers can shorten prototyping cycles. Companies that invest in digital twin approaches are likely to enjoy a time-to-market advantage and develop more innovative applications.

One of the fastest growing segments is automotive radar for ADAS (advanced driver-assistance systems) and full autonomy. Rogers 5870 Material’s low loss at millimeter-wave frequencies and stable dielectric properties over temperature variations make it attractive for radar sensors embedded in bumpers, roofs, and mirrors. My analysis suggests that as the cost of autonomous vehicle technology falls, large-volume procurement of Rogers 5870 Material will create economies of scale, which could offset its premium over lower-grade substrates.

At the same time, regulatory safety standards around radar performance will tighten, reinforcing the need for consistent dielectric materials. Here JM PCB could offer turnkey services to automotive Tier-1 suppliers, delivering Rogers 5870 Material-based PCBs ready for sensor integration.

Medical electronics—wearable monitors, imaging systems, and RF ablation devices—demand materials with predictable electrical behavior, biocompatibility, and reliability over long usage cycles. Rogers 5870 Material’s combination of low dielectric constant and minimal signal loss opens up new frontiers for non-invasive diagnostics and wireless patient monitoring. In my opinion, the growth of telemedicine and IoT health devices will drive miniaturized antennas and transmission lines, making Rogers 5870 Material an enabling technology.

Cost sensitivity in medical markets is high, but so is the willingness to pay for reliability and regulatory compliance. This duality means suppliers who can streamline Rogers 5870 Material manufacturing—again including specialists like JM PCB—will be in a strong competitive position.

Environmental stewardship is emerging as a key differentiator for material suppliers. Rogers 5870 Material production can be optimized for lower energy consumption and reduced volatile organic compound emissions. Recycling scrap and adopting closed-loop water systems during lamination help further reduce the environmental footprint.

My perspective is that as governments roll out stricter environmental standards, the ability to demonstrate sustainability in Rogers 5870 Material supply chains will become a decisive factor in large contracts, especially in Europe and parts of Asia. Manufacturers who combine advanced performance with eco-friendly credentials may command premium pricing even in commoditizing markets.

Rogers 5870 Material does not exist in a vacuum. Competitors such as Taconic, Isola, and Panasonic are continuously innovating with their own high-frequency laminates. Engineers weigh dielectric loss, moisture absorption, thermal conductivity, and price when selecting a substrate.

I believe Rogers 5870 Material’s long-standing reputation, technical documentation, and global support network give it an edge, but continuous improvement is essential. Companies that adopt hybrid stackups—combining Rogers-5870 Material with standard FR-4 in multilayer boards—can balance cost and performance, further extending its market reach.

Rogers-5870 Material has emerged as one of the most consistent and high-performing dielectric substrates for RF, microwave, and high-speed digital applications. In this article we walked through its material science fundamentals, its advantages, cost considerations, and diverse market opportunities — from 5G base stations to aerospace, automotive radar, and medical electronics.

The future of Rogers-5870 Material lies not only in incremental improvements but also in how it integrates into larger ecosystems. My view is that as companies pursue system-level innovation, materials will be co-designed with semiconductors, connectors, and thermal solutions. Rogers-5870 Material’s low-loss performance and stable dielectric constant make it an ideal foundation for such integrated solutions.

Another critical factor is sustainability. By investing in green manufacturing and closed-loop supply chains, Rogers 5870 Material suppliers can address both regulatory pressure and customer preference for environmentally responsible solutions. This, combined with strategic partnerships (for example with advanced PCB manufacturers like JM PCB), positions Rogers 5870 Material as more than a commodity — it becomes a differentiator.

Finally, Rogers 5870 Material’s ability to maintain consistent performance across temperature extremes, humidity, and long service life means it will continue to be trusted in mission-critical designs. Companies that adopt it early and optimize their designs around it are likely to enjoy performance advantages, lower total cost of ownership, and faster time-to-market.

In summary, the enduring value of Rogers 5870 Material can be captured in four pillars:

Performance: Low loss, stable dielectric constant, and strong thermal stability.

Cost-Effectiveness over Lifecycle: Higher initial costs offset by improved reliability and lower maintenance.

Sustainability and Compliance: Meeting emerging global standards.

Ecosystem Partnerships: Working with fabricators such as JM PCB to deliver optimized PCBs.

I believe that with these pillars, Rogers 5870 Material will remain a reference material in high-frequency markets well into the next decade.

1. What should designers consider when selecting Rogers-5870 Material thickness?

Dielectric thickness directly influences impedance, signal loss, and mechanical stability. Thinner cores reduce transmission line loss but may increase fabrication complexity. Designers should consult material datasheets and, when possible, collaborate with experienced PCB manufacturers such as JM PCB to ensure optimal stackup.

2. What makes Rogers-5870 Material different from standard FR-4?

Rogers-5870 Material has a much lower dielectric loss and a more tightly controlled dielectric constant compared to FR-4. This results in significantly better high-frequency performance and lower signal attenuation. FR-4 may be cheaper but it’s less suitable for RF and microwave designs.

3. Why is thermal management important when using Rogers-5870 Material?

High-frequency and high-power circuits generate substantial heat. Rogers-5870 Material offers superior stability under thermal stress, maintaining signal integrity and preventing board warping or delamination. Proper heat dissipation extends the lifetime of the PCB and reduces field failures.

4. How does Rogers-5870 Material compare to PTFE-based substrates?

Rogers 5870 Material provides comparable low-loss properties but with better dimensional stability and easier processing than many pure PTFE substrates. This reduces manufacturing complexity, lowers scrap rates, and can shorten lead times.

5. Can Rogers-5870 Material be combined with standard FR-4 in hybrid stackups?

Yes. Many manufacturers design hybrid PCBs that use Rogers 5870 Material for RF/high-speed layers while using FR-4 for power or low-speed layers. This approach balances cost and performance and is widely adopted in 5G base stations, aerospace modules, and advanced automotive radar systems.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote