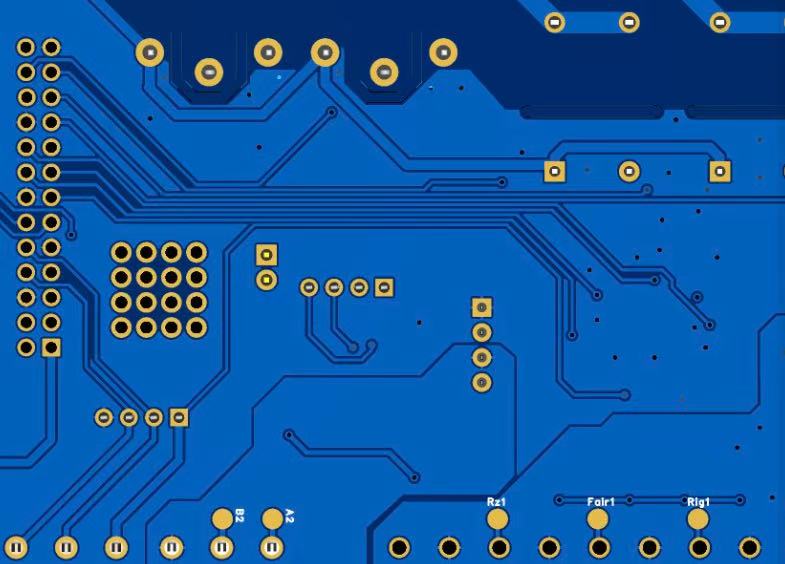

Over the last decade, printed circuit boards have undergone a radical transformation from relatively simple interconnection platforms to high-density, high-frequency transmission ecosystems. As designs transition from megahertz signals to multi-gigabit transmission lines, the smallest physical irregularities can destabilize system performance. Among these challenges, the Stub Effect is one that tends to be underestimated in early design stages, misunderstood in signal-integrity simulations, and mismanaged in manufacturing workflows.

What makes this phenomenon particularly deceptive is its invisibility. The Stub Effect is not visible in operation, does not inherently short or open circuits, and presents no immediate functional failure in low-speed systems. Instead, it manifests as a subtle, insidious disruptor, steadily degrading frequency response, producing signal reflections, and eroding noise margins in high-speed designs. This invisibility often delays mitigation until a costly redesign, late-stage re-tooling, or performance compromise becomes unavoidable.

Stub Effect

The Stub Effect refers to residual, unused via barrel segments connected to a transmission line between layers, acting as unintended transmission line stubs. These leftover conductive cavities behave as resonant elements that reflect incident signals, introducing discontinuities and degrading signal integrity.

To break it down simply:

A via is drilled to connect multiple layers

A signal may only use a portion of the barrel

The unused portion remains electrically connected

This unused section becomes a parasitic stub that reflects energy back into the active trace

The scale of this problem correlates directly with high-frequency signal transitions:

At low frequencies, the parasitic segment is electrically negligible

At multi-gigahertz frequencies, even fractional millimeter lengths can create resonances

One of the key reasons the Stub Effect is often misunderstood is that designers assume that signal propagation through vias is instantaneous. However, transmission lines operate according to:

Characteristic impedance (Z0)

Electromagnetic wave propagation

Distributed capacitive and inductive effects

Thus, a via is not a “wire”—it is an imperfect vertical transmission line with non-ideal termination.

Understanding this distinction is essential because many PCB issues historically attributed to “EMI problems,” “lossy materials,” or “design noise” are in fact the downstream consequences of unmitigated stubs.

The most common cause is via structures that extend deeper than necessary for a given connection. Designers often employ full-stack through-holes to simplify fabrication, but signals may exist on only two of the many layers, leaving unused sections above and below.

Example:

Signal transitions from L2 to L4

Via drilled from L1 to L8

L1-L2 and L4-L8 segments become unused stubs

This design approach is cost-efficient but electrically inefficient.

In some PCB manufacturing environments, restrictions on:

Drill technology

Layer tolerances

Sequential build-up techniques

force designers into suboptimal via configurations.

For instance, when microvias or stacked vias are not available, designers default to full-through holes.

This tradeoff is still common in smaller manufacturers, but increasingly obsolete in high-speed design ecosystems.

The Stub Effect introduces a broad range of electrical penalties, many of which are cumulative.

Unused via segments act as impedance discontinuities, sending part of the signal energy backward, leading to:

Increased return loss

Waveform distortion

Reduced signal amplitude

This phenomenon is worsened by fast edge rates.

Interestingly, signals with identical frequencies but different slew rates may experience entirely different reflection profiles.

The presence of a stub introduces frequency-dependent attenuation due to:

Dielectric losses

Copper wall losses

Energy trapped in resonance modes

Engineers sometimes misdiagnose this as “material loss,” leading to unnecessary specification upgrades.

Stubs can generate evanescent fields that:

Couple into adjacent vias or traces

Create multi-path interference

Reduce channel isolation

This effect becomes particularly problematic in dense backplanes and high-layer-count server boards.

The modern PCB ecosystem does not treat the Stub Effect as an inconvenience; rather, it views it as a parameter needing optimization through mechanical, chemical, and electromagnetic solutions. Mitigation therefore cannot be limited to schematic-level alterations; it must be embedded into the manufacturing infrastructure.

Many fabrication strategies have emerged, each with varying trade-offs in cost, risk, scalability, and yield. Yet, these strategies share a common objective: reducing unused conductive volumes without compromising existing connectivity.

In practice, the choice of mitigation strategy is seldom purely technical—it is shaped by the organization’s risk tolerance, cost priorities, and performance goals. The best engineers understand that technical solutions are constrained by economic realities.

Backdrilling is the most widely adopted technique for reducing unused via barrels in high-speed designs. It involves mechanically removing the unused segments of plated-through vias after traditional drilling and plating operations are complete.

Key advantages include:

Significant reduction in return loss

Lower resonance energy accumulation

Simplified modeling and validation

Minimal disruption to stack-up design

The process also carries inherent challenges:

Increased drill time

Higher per-panel cost

Additional QA steps

Engineers often misunderstand backdrilling as a cosmetic optimization, but its impact on high-frequency channels is structural rather than marginal. Measured improvements in performance often include reductions in:

Eye closure

Jitter amplitude

Bit error rate

From my perspective, organizations designing backdrilling out of a project because “it costs too much” reveal a short-term mindset. In high-rate serial links, the cost of field failures or performance limitations dwarfs incremental manufacturing expense.

Blind and buried vias naturally eliminate unwanted via depth. They are no longer exotic technologies—they are mainstream implementations in HDI architecture.

Advantages:

Reduced parasitic capacitance

Reduced inductance and delay

Improved routing density

Low stub length by design

However, non-trivial tradeoffs exist:

More complicated lamination cycles

Higher scrap risk

Longer tooling times

Need for tighter precision

One practical limitation is that many PCB businesses lack the infrastructure to build dense HDI with predictable yields. That is why partner selection becomes a performance variable, not a purchasing decision.

| Item | Description | Risk Level | Cost Impact |

|---|---|---|---|

| Cause: Via Stub | Unused length of via barrel below active layer | High (HF) | Medium |

| Cause: Trace Branch | Unused branch trace connected to high-speed net | Medium | Low |

| Impact: Reflection | Signal energy returns to source, causing distortion | High | Medium |

| Impact: Resonance | Stub acts like an antenna, causing EMI | High | High |

| Impact: Insertion Loss | Reduced signal amplitude over distance | Medium | Medium |

| Fix: Backdrilling | Drills out unused via length | Very Effective | High |

| Fix: Blind Vias | Avoid long via structures | Very Effective | High |

| Fix: Routing Optimization | Shorten or remove branches | Effective | Low |

| Fix: Controlled Impedance | Model stub behavior in design | Moderate | Low |

| Testing: TDR | Detects discontinuities in signal path | High Value | High |

The exploration of the Stub Effect in high-speed PCB manufacturing reveals a subtle but powerful design trap that silently sabotages signal performance. Although it may appear as a small geometric artifact—just an unused via segment or un-terminated trace—the Stub Effect introduces reflections, resonances, and losses that compromise timing budgets, distort waveforms, and weaken electromagnetic compatibility.

Modern electronic systems push signal integrity to unprecedented limits. In this environment, even minor discontinuities in impedance can become major contributors to system instability. As such, the Stub Effect is not merely a niche engineering concern—it is a systemic reliability threat that must be proactively controlled.

The manufacturing ecosystem has introduced multiple mitigation strategies: backdrilling, sequential lamination, controlled impedance routing, and via-in-pad technologies. Each method has benefits and trade-offs relating to cost, yield, manufacturability, and frequency range. Yet none of them is completely effective in isolation. True control of this phenomenon requires holistic design discipline, accurate modeling, and close communication between layout engineers, fabricators, and test engineers.

One of the most overlooked dimensions of the Stub Effect is that it forces designers to think beyond simple connectivity optimization, and toward three-dimensional signal behavior. Successful teams acknowledge that signal integrity originates not at debugging, but at stackup planning, via strategy, and routing philosophy.

Ultimately, the challenge posed by the Stub Effect is a reminder that PCB engineering is a multi-domain problem where physics, manufacturing realities, and cost pressures meet. The engineers who embrace this complexity—not avoid it—will build systems that deliver higher speeds, better energy efficiency, and more robust performance in an increasingly competitive technological landscape.

The Stub Effect is caused by unused or unterminated conductive segments, such as via stubs or trace stubs. These segments act as resonant structures that reflect signals back into the transmission path, degrading signal integrity.

At high frequencies, the wavelength of the signal becomes comparable to the length of the stub. This increases resonance and reflection. As operating frequency crosses key thresholds (e.g., several GHz), even very short stubs become problematic.

It introduces:

Signal reflections

Insertion loss

Distortion and jitter

Mode conversion

EMI/EMC problems

All of which can lead to timing violations, data corruption, or system instability.

Common mitigation strategies include:

Backdrilling

Blind or buried vias

Via-in-pad technologies

Routing optimization

Improved stackup design

Each approach must be tailored to the application’s frequency and performance targets.

No. Backdrilling is highly effective for GHz+ designs, but it adds cost, cycle time, and may be unnecessary for lower-frequency systems. Simulation and cost analysis should precede commitment.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote