Heavy Copper Circuit Construction

Standard printed circuit boards, whether double-sided or multilayer, are manufactured

using a combination of copper etching and plating processes. Circuit layers start as

thin sheets of copper foil that are etched to remove unwanted copper, and plated to add

copper thickness to planes, traces, pads and plated-through-holes. All of the circuit

layers are laminated into a complete package using an epoxy-based substrate, such as FR4

or polyimide.

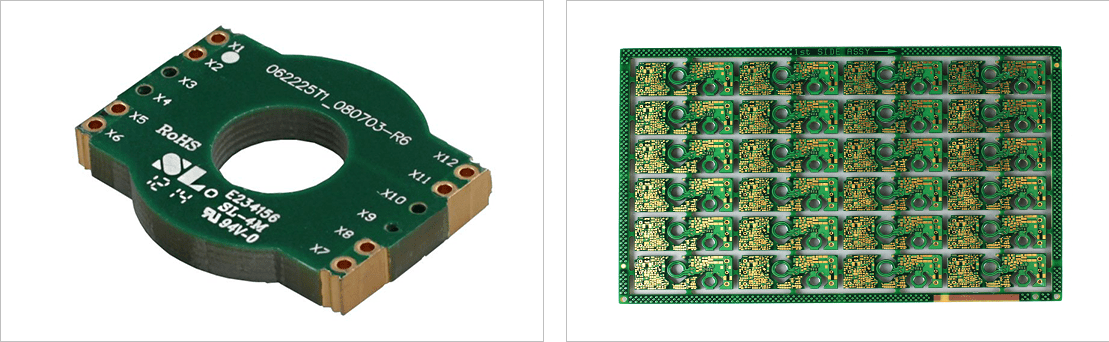

Boards incorporating heavy copper circuits are produced in exactly the same way, albeit

with specialized etching and plating techniques, such as high-speed/step plating and

differential etching. Historically, heavy copper features were formed entirely by

etching thick copper clad laminated board material, causing uneven trace sidewalls and

unacceptable undercutting. Advances in plating technology have allowed heavy copper

features to be formed with a combination of plating and etching, resulting in straight

sidewalls and negligible undercut.

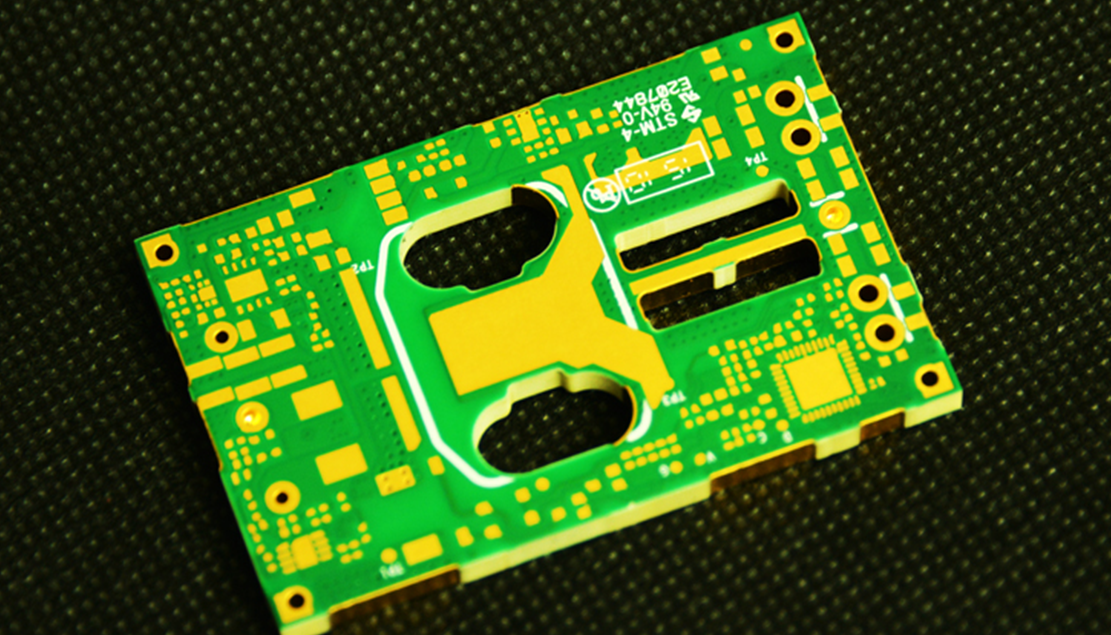

Plating of a heavy copper circuit enables the board fabricator to increase the amount of

copper thickness in plated holes and via sidewalls. It’s now possible to mix heavy

copper with standard features on a single board, also known as PowerLink. Advantages

include reduced layer count, low impedance power distribution, smaller footprints and

potential cost savings. Normally, high-current/high-power circuits and their control

circuits were produced separately on separate boards. Heavy copper plating makes it

possible to integrate high-current circuits and control circuits to realize a highly

dense yet simple board structure.

The heavy copper features can be seamlessly connected to standard circuits. Heavy copper

and standard features can be placed with minimal restriction provided the designer and

fabricator discuss manufacturing tolerances and abilities prior to final design