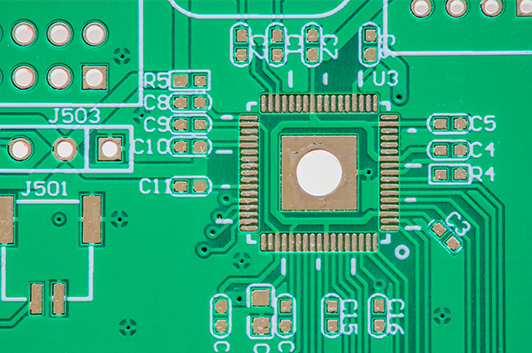

In the world of modern electronics, printed circuit boards (PCBs) are the foundation upon which nearly all digital and analog devices are built. From the smartphones in our pockets to aerospace communication systems orbiting the Earth, PCBs provide the electrical interconnection platform that allows billions of components to function harmoniously. While engineers and consumers alike tend to focus on speed, density, or miniaturization, one visual detail often goes unnoticed: the green color that dominates PCBs worldwide.

The overwhelming majority of PCBs are coated with a green solder mask, the thin protective polymer layer that insulates copper traces and prevents solder bridges during assembly. Yet the choice of green is not merely aesthetic. It is tied to a deeper question of manufacturing history, material science, optical properties, human factors, and ultimately reliability.

This article, titled “A Question of Reliability: What is the Reason Why Green Became the Standard for PCB Solder Mask?”, explores the subject comprehensively. It will trace the historical origins, analyze the scientific and practical benefits, and consider why alternatives such as red, blue, black, or even white have not displaced green as the dominant color in the electronics industry. Importantly, we will also examine how this color contributes to PCB reliability, why it matters in terms of inspection and performance, and what future trends may hold.

Why Green Became the Standard for PCB Solder Mask

The story of why green became the standard for PCB solder mask begins with the development of solder mask materials in the mid-20th century. Early PCBs, especially during the 1940s and 1950s, lacked protective solder mask coatings altogether. They were prone to oxidation, mechanical damage, and solder bridging during assembly. As circuits became denser, manufacturers needed a resilient, insulating polymer coating that could prevent shorts while withstanding soldering temperatures.

Epoxy resins were introduced as a solution, and the earliest commercial solder masks were often pigmented green due to the natural coloration of the resins combined with certain curing agents and pigments. This green pigment happened to provide excellent contrast for human inspectors, making defects such as cracks, shorts, and misaligned solder joints more visible under normal factory lighting.

Another significant factor was the military and aerospace adoption of green PCBs during the 1960s and 1970s. Because these industries demanded high reliability and rigorous inspection processes, the green solder mask became standardized in defense contracts. Once defense suppliers established large-scale production with green solder masks, economies of scale made it practical for commercial industries to follow.

From this historical standpoint, green’s dominance was not just an accident of chemistry, but rather the outcome of practical inspection needs, reliability demands, and manufacturing momentum.

One of the strongest arguments for why green became the standard for PCB solder mask lies in the optical advantages of the color green. Human vision is most sensitive to the green region of the spectrum, around 555 nm wavelength. This makes fine details, small solder bridges, and hairline cracks easier to detect against a green background than against darker or lighter alternatives.

In manual visual inspection environments, where workers had to check hundreds of PCBs per shift, green reduced eye strain and fatigue, improving accuracy and efficiency. Even today, with automated optical inspection (AOI) systems, green remains advantageous because camera sensors and machine-vision algorithms work effectively with the high-contrast features provided by green masks.

Moreover, green provides a balanced reflectivity: it is neither too dark (like black, which hides defects) nor too bright (like white, which causes glare). This balance made it the default choice for decades of mass production.

Beyond human vision and historical precedent, the green solder mask has direct reliability implications. Several factors contribute:

Material Stability – Green pigments, often derived from stable metal oxides, exhibit excellent resistance to UV degradation and thermal cycling. This stability reduces the risk of discoloration or brittleness, which could otherwise compromise insulation.

Process Compatibility – The curing and photoimaging processes used in PCB manufacturing were historically optimized for green solder mask formulations. Green masks tend to show fewer process defects, such as uneven curing or delamination, compared to less common colors.

Surface Clarity During Assembly – During solder reflow, the green mask allows clear visibility of solder paste, flux residue, and component alignment. This visibility aids both human operators and automated pick-and-place machines, indirectly improving yield.

Thermal and Chemical Endurance – Since soldering often involves temperatures above 250°C, the pigment and resin must endure without outgassing, bubbling, or decomposing. Green solder masks consistently demonstrated robust reliability in harsh assembly conditions.

From my perspective, this is where color intersects directly with reliability. While other solder mask colors can offer aesthetic differentiation, few can match green’s proven track record in minimizing defects and ensuring long-term circuit stability.

The advantages of green solder masks can be summarized across multiple dimensions:

Manufacturing Efficiency: Decades of process tuning around green masks mean lower defect rates and better yield.

Inspection Reliability: Human inspectors and AOI systems achieve higher defect detection accuracy.

Environmental Durability: Resistance to heat, light, and humidity extends product life.

Standardization and Cost: As the industry standard, green is cheaper and more widely available than specialty colors.

In terms of PCB reliability, green masks serve as a barrier against moisture ingress, ionic contamination, and accidental bridging. This barrier ensures that conductive pathways remain isolated, preventing corrosion and electrical shorts.

When analyzing why green became the standard for PCB solder mask, it is equally important to evaluate the alternatives. Over the years, several different solder mask colors—red, blue, black, white, and even purple—have been introduced to the market. Each has its appeal, but none has dethroned green as the industry’s dominant choice.

Red Solder Masks – Red PCBs are often chosen for branding or aesthetic differentiation, especially in consumer electronics or high-end hobbyist products. While red provides decent visibility, it does not match green in terms of contrast during inspection. Under bright factory lights, red can strain the eyes more quickly than green.

Blue Solder Masks – Blue is popular in certain professional audio and computing products, as it offers a modern, sleek look. However, blue lacks the balance of green: defects can be harder to spot, and AOI cameras may require recalibration for proper detection.

Black Solder Masks – Black solder masks are considered “premium” by some customers due to their elegant appearance, particularly in visible PCBs such as gaming GPUs. Unfortunately, they significantly reduce visibility of fine details, making inspection much harder. Black also absorbs more heat during soldering, which can complicate thermal management.

White Solder Masks – White masks are typically used for LED applications, since they help reflect light and increase brightness. However, they suffer from discoloration over time and easily reveal dirt, scratches, and surface irregularities.

Purple or Specialty Colors – Occasionally, purple, yellow, or even transparent masks are produced for aesthetic reasons. Yet these are niche products, often expensive, and not suitable for mass production environments.

From this comparison, the conclusion is clear: green strikes the best balance between practicality, cost, reliability, and visibility. This explains why it became—and remains—the default choice.

Another reason why green became the standard for PCB solder mask relates to manufacturing optimization. Most PCB fabrication facilities are designed around green mask processing because:

Photoimaging Performance: Green masks respond predictably during the UV exposure step, yielding precise patterns with minimal errors.

Curing Uniformity: Green pigment mixes well with epoxy or LPI (liquid photoimageable) solder mask resins, curing evenly under heat and UV light.

Layer Contrast: During multilayer PCB fabrication, green provides excellent visual separation of copper, solder, and silkscreen layers.

AOI Compatibility: Automated inspection machines are tuned to green reflectivity, minimizing false positives.

In my view, the self-reinforcing cycle of standardization is a powerful driver. Because the industry heavily invested in green-mask-friendly processes, manufacturers and suppliers optimized materials, equipment, and inspection tools accordingly. As a result, alternative colors face both technical and economic barriers to adoption.

In large-scale electronics manufacturing, cost efficiency is critical. Green solder masks dominate because they are:

Mass-Produced at Lower Cost – Since green pigments and formulations are produced in the highest volumes, economies of scale keep prices down.

Widely Stocked Globally – Every major PCB fabricator carries green masks, ensuring availability and reducing lead time.

Reduced Scrap Rates – Manufacturing processes tuned for green produce fewer rejects, saving costs.

When considering PCB projects with tight budgets, especially in industries like consumer electronics, this cost advantage is significant. While other colors may serve niche markets, green remains unmatched in price-to-reliability ratio.

Reliability testing is a vital stage in PCB qualification. Tests such as thermal cycling, humidity resistance, solderability, and mechanical stress assessments are easier to evaluate on green boards.

Defect Detection: Cracks, delamination, or solder ball residues are more visible.

Consistency: Test data across facilities is standardized, making green boards the baseline reference.

Reliability Confidence: Since military and aerospace industries long trusted green, it established itself as the gold standard for reliability certification.

Here I want to pause and add my personal reflection: green’s dominance is not just historical inertia. Even if other colors were equally reliable, the fact that green has decades of validation data makes it the most trustworthy baseline for reliability engineers.

Today, most PCB orders default to green solder masks unless a customer specifies otherwise. This is not simply a matter of tradition—it is a matter of streamlined global supply chains.

Assembly houses assume green boards for inspection setup.

Rework technicians are trained primarily on green.

Documentation, IPC standards, and CAD software libraries often show green as the reference.

This widespread standardization reduces ambiguity, errors, and overhead costs. For companies that prioritize speed and quality, green is the most logical choice.

The rise of HDI technology—with microvias, fine-pitch components, and stacked vias—pushed PCB manufacturing to new limits. In these designs, solder mask precision becomes even more critical, because spacing between pads and traces can be less than 100 microns.

Green solder masks provide:

High imaging accuracy: They perform consistently in liquid photoimageable (LPI) processes, ensuring sharp mask definition for tiny pads.

Low defect rates: In HDI, a single solder bridge can ruin an entire board. Green’s proven imaging reliability reduces this risk.

Better AOI readability: AOI machines identify defects more effectively on green masks, which is vital when thousands of microvias must be inspected.

Reflecting on this, I believe that while alternative colors may serve aesthetic needs, green remains unmatched in functional alignment with advanced PCB technologies. It is not simply tradition—it is an enabler of next-generation electronics reliability.

Flexible PCBs (FPCs) and rigid-flex boards often require different processing techniques compared to rigid boards. Even here, green solder masks dominate for several reasons:

Material Compatibility – Polyimide-based substrates in flex PCBs require solder masks that can adhere without cracking during bending. Green formulations have undergone the most optimization for this requirement.

Inspection Efficiency – Rigid-flex designs are already complex. Using green masks reduces inspection errors by providing better trace visibility.

Thermal and Mechanical Reliability – Flex circuits in aerospace, automotive, and medical devices must endure bending, heat, and vibration. Green solder masks have accumulated decades of reliability data in these conditions.

From my perspective, the choice of green in flex applications shows that reliability outweighs aesthetics. Companies building medical implants or automotive safety systems would never risk product integrity just to have a black or red flex PCB.

Modern PCB manufacturing relies heavily on AOI systems to check for defects. Green solder masks offer multiple advantages here:

Optimal Contrast with Copper and Silkscreen: AOI algorithms are tuned to green backgrounds, allowing fast and accurate defect detection.

Reduced False Negatives: Colors like black or blue can confuse image processing software, leading to undetected defects.

Uniform Reflectivity: Green prevents glare, making AOI more reliable across different lighting setups.

If we think critically, AOI represents one of the strongest reasons why green will remain dominant for the foreseeable future. Recalibrating global inspection systems to alternative colors would be costly and error-prone.

With sustainability becoming a central issue in electronics manufacturing, green solder masks also hold an advantage:

Established Supply Chain – Green pigments are widely produced, reducing the need for exotic or environmentally harmful alternatives.

Lower Waste – Since processes are optimized for green, defect rates are minimized, reducing scrap material.

Future Eco-Friendly Adaptations – Researchers developing bio-based or halogen-free solder masks often use green as the baseline, ensuring compliance with RoHS and REACH standards.

In my reflection, the environmental story reinforces green’s dominance. The fact that green solder masks are both mature and adaptable means they can evolve with future eco-regulations without disrupting manufacturing stability.

Looking forward, some industry observers ask whether green will remain the standard or if new demands will shift preferences. Possibilities include:

Miniaturization and Optical Alignment – As boards become smaller, colors optimized for machine vision (possibly not green) might be introduced.

Brand Differentiation – Consumer-facing companies may push harder for custom colors to create product identity.

Nanomaterial Pigments – Future masks may use advanced pigments that improve thermal conductivity or ESD resistance, potentially changing standard colors.

Transparent Masks – For highly specialized circuits, clear solder masks may allow for direct copper visualization.

Yet, from my own reasoning, I believe green will continue to dominate because of its entrenched infrastructure. The electronics industry is highly risk-averse when it comes to reliability, and green has decades of data proving its effectiveness. Alternatives may grow in niche markets, but the global baseline will likely stay green.

Consumer electronics is the largest market for PCBs, covering smartphones, laptops, wearables, gaming devices, and home appliances. In this fast-moving sector, reliability and cost efficiency are critical. Green solder masks remain the standard for several reasons:

Mass Production Efficiency – Consumer electronics demand millions of units, often with short product cycles. Green solder masks reduce costs and defects, making them ideal for high-volume runs.

Quality Consistency – End-users may never see the PCB inside their phone or laptop, but performance failures are unacceptable. Green ensures consistent manufacturing results across global facilities.

Compatibility with Testing Systems – Contract manufacturers rely heavily on AOI and in-circuit testing (ICT). Green makes both processes faster and more accurate.

From my perspective, the invisible backbone of consumer technology depends on green solder masks. Even though consumers value sleek exterior designs, the industry prioritizes proven reliability for what lies inside.

Automotive electronics are exposed to extreme thermal cycles, vibrations, and humidity. Whether it is engine control units (ECUs), infotainment systems, or advanced driver assistance systems (ADAS), PCBs must meet stringent reliability requirements.

Green solder masks dominate here because they provide:

Thermal Endurance – Able to withstand under-hood environments exceeding 125°C.

Moisture Resistance – Protect copper from corrosion in humid conditions.

Ease of Defect Detection – Automotive manufacturers demand zero-defect strategies, and green allows better visual and AOI inspections.

I think it is telling that automotive electronics—where human lives depend on reliability—still overwhelmingly rely on green solder masks. This reinforces that the color choice is not trivial; it is a core enabler of functional safety.

In medical electronics, failure is simply unacceptable. Devices like pacemakers, diagnostic imaging equipment, and monitoring systems must function flawlessly for years.

Green solder masks remain dominant in this field for three main reasons:

Regulatory Confidence – Green has decades of validation data under IPC and ISO standards, easing the certification process for medical devices.

Defect Visibility – In surgical tools or life-support systems, PCB defects can be fatal. Green minimizes undetected flaws.

Proven Long-Term Stability – Medical devices often require reliability over 10–20 years. Green solder masks provide proven endurance against UV, sterilization processes, and long storage.

Here, I believe green is not just a technical standard—it is an ethical safeguard. Patients’ lives are protected by the reliability built into these PCBs, and the green solder mask is an integral part of that assurance.

As factories shift toward Industry 4.0, AI-powered inspection systems are becoming more common. Machine learning models are trained to detect defects in PCBs, and the datasets used for training are overwhelmingly based on green solder mask imagery.

Consistency in Data Training – AI algorithms perform best with consistent training data. Green provides this baseline across global industries.

Reduced Noise in Imaging – Green solder masks create a balanced contrast that improves defect detection accuracy in neural networks.

Scalability – As AI expands across different manufacturers, green serves as the universal language of defect recognition.

From my perspective, AI will further entrench green’s dominance, because retraining AI models for multiple mask colors introduces unnecessary variability and cost.

In smart factories, automation extends beyond inspection into assembly, reflow soldering, rework, and packaging. Here too, green solder masks are advantageous:

Pick-and-Place Machine Calibration – Green provides contrast with solder paste, helping cameras align components with higher precision.

Reflow Monitoring – Green masks withstand repeated thermal profiles without discoloration, aiding real-time monitoring systems.

Traceability Systems – Barcodes and silkscreen markings are more readable against green, improving traceability.

If we critically evaluate this, the synergy between green solder masks and automation means that factories achieve both higher yield and lower downtime. This is why green remains the logical baseline color in an era defined by digital transformation.

Another perspective on Why Green Became the Standard for PCB Solder Mask relates to environmental compliance and sustainability. With the rise of RoHS, WEEE, and REACH regulations, PCB manufacturers must ensure that their solder mask materials meet strict environmental requirements.

Green solder mask formulations were the first to be adapted to comply with halogen-free and low-VOC (volatile organic compound) standards. As such, they became the reference point for environmental safety in the industry. Newer alternative colors sometimes lag behind in certifications, while green maintains its trusted reputation.

In addition, manufacturers have refined the production process of green solder mask to minimize waste, reduce curing energy consumption, and ensure consistent quality in mass production. This further reinforces why green remains the eco-friendly and reliable option in large-scale PCB fabrication.

When considering high-volume PCB manufacturing, the question of Why Green Became the Standard for PCB Solder Mask connects directly to efficiency.

Green solder mask has the fastest processing times, most predictable curing profiles, and widest compatibility with screen printing, spray coating, and curtain coating methods. Because it has been produced and tested in massive volumes worldwide, every stage of manufacturing — from material storage to UV curing — is streamlined when using green.

This efficiency translates into shorter production cycles, fewer rejects, and ultimately lower costs. For manufacturers seeking both speed and reliability, green solder mask represents the safest and most proven pathway.

To summarize the exploration of Why Green Became the Standard for PCB Solder Mask, it is clear that this dominance is not a coincidence but the result of multiple overlapping factors:

Technical Reliability: Green solder mask withstands high heat, resists cracking, and provides consistent performance across industries.

Manufacturing Efficiency: Decades of optimization have made green solder mask the fastest, most cost-effective option for large-scale production.

Inspection Advantage: The optical properties of green improve both human and machine inspection, ensuring higher yields and fewer defects.

Environmental Compliance: Green solder mask has led the way in meeting RoHS and eco-friendly manufacturing standards.

Historical Momentum: Early adoption and subsequent global standardization entrenched green as the universal choice for reliability.

Across industries — from consumer electronics to automotive, aerospace, and beyond — green has proven itself as the color of reliability. It is not simply tradition but a rational outcome of engineering, economics, and trust built over decades. Ultimately, green will remain the benchmark against which all other solder mask colors are measured — not because it is the only option, but because it has consistently demonstrated that reliability is not just about design, but also about the materials we choose.

What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

Why are most PCBs not made with black solder masks?

Black solder masks make inspection difficult because defects are harder to see. They also tend to show dust, scratches, and surface irregularities more visibly, which complicates quality control.

Does solder mask color affect electrical performance?

Generally, no. The solder mask color is primarily aesthetic and practical for inspection, but the base polymer properties matter more for insulation and durability.

Can I request custom solder mask colors for my PCBs?

Yes. Many manufacturers, including JM PCB, offer alternatives like red, blue, white, and even transparent masks. However, these may increase cost or lead time.

How does solder mask contribute to PCB reliability?

The solder mask prevents oxidation, protects traces from contamination, and reduces solder bridging during assembly. It is essential for ensuring long-term circuit performance.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote