The landscape of electronic design has evolved dramatically in recent decades, driven by the demand for higher performance, miniaturization, and operation in increasingly harsh environments. Among the many materials available to printed circuit board (PCB) designers, polyimide-based boards stand out as a premium choice for applications that demand exceptional thermal stability, mechanical resilience, and long-term reliability.

Polyimide PCBs are constructed using a polyimide resin system as the base material, replacing or supplementing the standard FR4 epoxy resin used in most conventional boards. Polyimide, a polymer known for its remarkable heat resistance and mechanical toughness, enables PCBs to withstand conditions that would cause traditional FR4 boards to degrade or fail prematurely.

While FR4 PCBs are sufficient for many consumer electronics, there is a growing segment of the electronics industry that requires more robust solutions — aerospace control systems, high-speed communications infrastructure, and advanced automotive electronics are just a few examples. For these sectors, the benefits of polyimide far outweigh the higher cost of production.

From a chemical perspective, polyimide is an aromatic heterocyclic polymer, meaning it has a rigid molecular structure that resists deformation even under extreme temperatures. This property allows polyimide PCBs to perform reliably in temperature ranges from –200°C to over +300°C, far exceeding FR4’s limits. This thermal stability is not just a theoretical advantage — it translates into tangible benefits in soldering, reflow cycles, and operation in demanding industrial settings.

The shift toward polyimide is not simply a matter of “more expensive equals better.” It reflects a strategic choice in engineering: when product failure is unacceptable, engineers turn to materials like polyimide to reduce risk and extend service life. In this sense, polyimide PCBs are not replacing FR4 everywhere — they are targeted solutions for high-value, high-reliability applications.

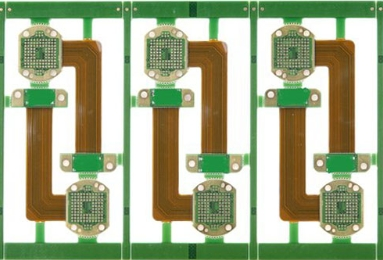

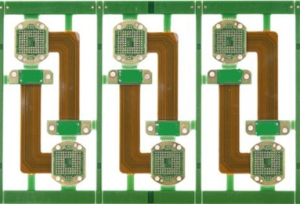

Polyimide PCBs

The most fundamental difference between polyimide PCBs and FR4 boards lies in the resin system that binds the glass fiber reinforcement. FR4 uses an epoxy resin, while polyimide boards use a polyimide resin. This single difference in chemistry cascades into multiple distinctions in thermal, mechanical, and chemical properties.

2.1 Thermal Stability

FR4 materials typically have a glass transition temperature (Tg) around 130–140°C, with high-Tg FR4 reaching up to 170°C. In contrast, polyimide systems can exhibit Tg values exceeding 250°C. The higher Tg translates to a greater ability to maintain mechanical integrity and dielectric performance at elevated temperatures. This property is especially important for aerospace and defense electronics, where components may face continuous thermal cycling.

2.2 Mechanical Performance

Polyimide PCBs are generally more dimensionally stable under stress. They resist warping and maintain layer alignment better than FR4 when subjected to extreme thermal excursions. This makes them ideal for multilayer designs where precise registration is critical.

2.3 Moisture Absorption and Chemical Resistance

While FR4 can absorb small amounts of moisture, polyimide materials tend to have slightly higher moisture absorption rates — a drawback that must be addressed through protective coatings or controlled storage. However, polyimide’s resistance to chemical degradation is superior, enabling it to survive exposure to aggressive solvents and cleaning agents used in manufacturing or maintenance.

2.4 Cost and Manufacturing Implications

One of the main reasons FR4 remains dominant is cost. Polyimide PCBs require more expensive raw materials and, in some cases, longer lamination cycles. They also demand careful process control to avoid defects like resin voids. These factors contribute to a higher per-unit price, making them viable primarily for applications where failure costs exceed manufacturing cost differences.

2.5 Electrical Performance

In high-speed and high-frequency applications, dielectric properties become critical. Polyimide resins generally offer a slightly lower dielectric constant (Dk) than FR4, which can result in reduced signal loss and better impedance control. This can be a decisive advantage in telecommunications and radar systems.

In short, the polyimide-versus-FR4 decision boils down to the intended use case. For budget-sensitive consumer devices, FR4’s lower cost makes sense. For mission-critical applications where performance margins must remain wide, polyimide earns its place despite the cost premium.

One of the most widely recognized benefits of polyimide-based boards is their ability to operate consistently under extreme thermal conditions. Thermal performance is often the decisive factor when engineers choose between standard FR4 and high-end materials.

3.1 Operating Temperature Range

Polyimide PCBs can function reliably in temperatures ranging from cryogenic levels of –200°C to well above 250°C in continuous operation, with short-term endurance beyond 300°C. This is a stark contrast to standard FR4 materials, which typically begin to lose mechanical strength and dielectric stability above 130–140°C. Even high-Tg FR4 grades cannot match the upper limits of polyimide in thermal endurance.

3.2 Glass Transition Temperature (Tg) Advantage

The glass transition temperature is a key metric in PCB materials. When the Tg is exceeded, the resin matrix softens, mechanical properties degrade, and electrical characteristics can shift. Polyimide systems possess Tg values significantly higher than FR4, allowing them to endure lead-free soldering processes without degradation. This property is especially valuable for aerospace avionics or industrial equipment that may require multiple soldering and reflow cycles during assembly or maintenance.

3.3 Reduced Thermal Expansion Stress

Thermal expansion mismatches between the PCB and mounted components can induce mechanical stress, leading to solder joint fatigue or even trace cracking. Polyimide’s coefficient of thermal expansion (CTE) is lower and more stable over a wide temperature range compared to FR4, reducing the mechanical fatigue on connections and prolonging service life in thermally demanding environments.

3.4 Sustained Reliability in Thermal Cycling

Many defense and automotive systems experience repeated heating and cooling cycles — from a cold engine start in winter to full operational heat in minutes. Polyimide-based designs have been shown to retain dimensional stability and electrical integrity even after thousands of thermal cycles, significantly outperforming FR4, which can exhibit delamination or warping after fewer cycles.

3.5 Example Applications

This level of thermal robustness is not just a theoretical advantage; it is exploited in real-world designs such as satellite communications systems, downhole drilling tools, and fighter aircraft radar modules. In each case, a loss of electrical performance due to material degradation could result in costly mission failure — a risk engineers mitigate by selecting polyimide over FR4.

While thermal performance often gets the most attention, electrical performance is equally important, particularly in today’s high-speed, high-frequency applications. Material properties directly influence signal transmission quality, impedance stability, and overall system performance.

4.1 Dielectric Constant (Dk) Benefits

Polyimide resin systems generally exhibit a dielectric constant in the range of 3.2–3.5, which is slightly lower than standard FR4’s range of 3.9–4.5. This lower Dk reduces capacitance per unit length, improving signal speed and reducing dispersion in high-frequency applications. The benefit becomes particularly important in gigahertz-range circuits, such as radar front-ends and 5G infrastructure.

4.2 Lower Dielectric Loss (Df)

In addition to Dk, dielectric loss factor (Df) plays a critical role in determining how much signal power is dissipated as heat during transmission. Polyimide materials often achieve lower Df values than FR4, which means they contribute less to overall insertion loss. This is valuable for minimizing power requirements and maximizing link distance in RF systems.

4.3 Stability Across Temperature and Frequency

One often-overlooked advantage of polyimide over FR4 is the stability of its electrical parameters across temperature extremes. FR4’s Dk and Df can vary significantly with both temperature and frequency, complicating impedance control in high-speed designs. Polyimide’s stability allows engineers to maintain tighter design tolerances without overcompensating for thermal drift.

4.4 Crosstalk and EMI Reduction

Lower dielectric losses and more stable impedance profiles also help reduce crosstalk and electromagnetic interference (EMI). In high-density layouts, this can be the difference between passing and failing EMC compliance testing.

4.5 Relevance to Next-Generation Designs

As electronics push into the millimeter-wave spectrum (30 GHz and beyond), material choice becomes critical. Polyimide-based designs can sustain performance in these regimes without requiring exotic PTFE-based laminates, offering a balance of manufacturability and electrical excellence.

Producing a polyimide-based PCB requires precision at every stage. The inherent properties of the polyimide resin — higher thermal resistance, different curing behavior, and increased processing time — mean that manufacturing is somewhat more demanding than standard FR4 boards. However, when executed correctly, the result is a high-reliability product capable of withstanding the most punishing environments.

The process begins with the selection of polyimide laminates and prepregs. These materials are typically supplied with glass fiber reinforcement and a polyimide resin system, either as single-sided copper-clad laminates or as sheets for lamination. Care must be taken to store them in low-humidity conditions to minimize moisture uptake, as polyimide can absorb slightly more moisture than FR4.

Before processing, laminates are cut into panel sizes suitable for the production line. This step requires careful handling to avoid introducing stress cracks along the edges.

Polyimide’s toughness requires sharper drill bits and sometimes slower spindle speeds to maintain hole wall quality. Once drilling is complete, a desmear process removes any resin smear from the copper pads. Plasma etching is often preferred over chemical methods for polyimide boards because it provides a cleaner hole wall profile without over-etching.

Multilayer polyimide PCBs go through a lamination cycle similar to FR4 but with longer curing times and higher temperatures — often up to 220–240°C. The extended cure ensures full polymerization of the resin, maximizing its thermal and mechanical properties.

Photoresist application, UV exposure, and development follow industry-standard PCB processes. Polyimide’s high temperature tolerance allows for more aggressive etching cycles without damaging the base material. The copper patterning process must be controlled to avoid undercutting in fine-pitch circuits.

High-temperature solder masks are used to match the endurance of the underlying material. Surface finishes such as ENIG (Electroless Nickel Immersion Gold), immersion silver, or OSP (Organic Solderability Preservatives) are commonly applied. Lead-free HASL is also possible due to the high Tg of polyimide.

Electrical testing, automated optical inspection (AOI), and X-ray inspection are performed to verify quality. Polyimide PCBs intended for aerospace or military use often undergo additional thermal shock and vibration testing before shipment.

Mechanical performance is a critical aspect of PCB design, especially for products exposed to physical stress, vibration, or repeated bending. Polyimide-based boards excel in these conditions due to the inherent toughness and resilience of the resin system.

Polyimide maintains its shape and size over a broad temperature range, minimizing expansion and contraction. This dimensional stability prevents misalignment between layers in multilayer constructions and ensures plated through-holes remain intact after multiple thermal cycles.

One of the most attractive features of polyimide material is its natural flexibility when produced in thin laminates. This is why polyimide is often used in flexible circuits and rigid-flex designs. FR4, by contrast, becomes brittle when thinned, limiting its usefulness in bend-to-fit applications.

In high-vibration environments such as aircraft, military vehicles, or heavy industrial machinery, mechanical fatigue can lead to trace cracking and pad lift-off. Polyimide’s elasticity allows it to absorb and dissipate mechanical energy better than FR4, reducing the risk of structural failure.

While polyimide materials are not as soft as elastomers, their molecular structure gives them superior impact resistance compared to standard epoxy resins. This means a board can withstand accidental drops or shocks without delamination.

In wearable electronics or aerospace harness systems, rigid-flex boards using polyimide layers can be bent and routed through tight spaces without mechanical damage, something that would be nearly impossible with an FR4-only design.

Polyimide PCBs are uniquely suited to operate in conditions that would challenge or destroy conventional FR4 boards. Their combination of thermal endurance, chemical resistance, and mechanical stability makes them the material of choice for high-reliability applications.

As discussed earlier, polyimide materials maintain their properties over extremely wide temperature ranges. This makes them suitable for aerospace electronics, military radar systems, and oilfield instrumentation. Electronics exposed to high temperatures during operation or harsh environmental cycles require boards that do not deform, delaminate, or experience signal degradation.

In chemical processing plants or marine environments, PCBs may be exposed to aggressive cleaning agents, oils, or humidity. Polyimide’s superior chemical resistance allows circuits to maintain integrity where FR4 would absorb moisture, swell, or corrode. Protective coatings further enhance the board’s durability in these challenging conditions.

Vehicles, aircraft, and heavy industrial equipment often subject electronics to continuous vibration and occasional mechanical shocks. The flexibility and toughness of polyimide help prevent trace cracking, pad lifting, and other mechanical failures that would be common in standard epoxy boards.

Polyimide PCBs are widely used in satellites, unmanned aerial vehicles (UAVs), and military avionics, where extreme reliability is non-negotiable. Components can experience repeated thermal cycling, high radiation exposure, and vibration without loss of performance. These boards enable electronics that must operate flawlessly over long periods and in inaccessible locations.

For engineers seeking high-reliability polyimide PCBs, JM PCB offers specialized production services with stringent quality control tailored to harsh environment applications. Their expertise ensures that boards meet aerospace, defense, and industrial standards without compromise.

While polyimide PCBs deliver unmatched performance in demanding environments, cost is always a factor. Understanding the balance between material cost, manufacturing complexity, and reliability benefits is essential for making informed design decisions.

Polyimide resin is more expensive than standard epoxy, and the laminates are often sold at a premium. In addition, longer lamination cycles, careful drilling, and specialized handling increase production costs compared to FR4 boards. Designers must weigh these costs against the potential consequences of board failure.

In mission-critical systems, the cost of failure often dwarfs the material price difference. For aerospace, defense, or medical electronics, replacing a failed FR4 board in a deployed system could involve expensive repairs, operational downtime, or even safety hazards. In such cases, the upfront investment in polyimide PCBs is justified.

When evaluating the cost of a PCB, consider the total lifecycle. Polyimide boards tend to require less maintenance, endure longer service life, and reduce the need for redesigns or protective measures. This long-term reliability often offsets the higher initial cost, especially for high-value systems.

Using polyimide only where necessary, such as in the high-heat zones or flexible portions of a rigid-flex design, can help manage costs. Hybrid boards that combine FR4 for non-critical sections with polyimide in demanding areas allow designers to achieve performance without excessive expense.

Polyimide PCBs have become indispensable in industries where reliability, thermal endurance, and mechanical resilience are critical. These sectors face extreme operating conditions that standard FR4 boards cannot consistently withstand.

In aerospace, electronic systems operate in environments with extreme temperatures, pressure variations, and vibration. Avionics, satellite control systems, and navigation modules frequently employ polyimide PCBs to ensure operational integrity. Their low coefficient of thermal expansion, dimensional stability, and resistance to delamination under cyclic stresses make them ideal for these applications.

Modern vehicles are increasingly reliant on sophisticated electronics, from engine management units to advanced driver-assistance systems (ADAS). Polyimide PCBs perform reliably under high engine temperatures and mechanical vibration. They also maintain electrical stability for sensors and communication modules critical for safety and autonomous driving functionality.

Heavy machinery, robotics, and energy systems often expose electronics to high ambient temperatures, dust, chemicals, and mechanical shocks. Polyimide PCBs are well-suited for such harsh environments. Their ability to maintain signal integrity and mechanical strength reduces downtime and maintenance costs, particularly in production lines and energy distribution networks.

Across aerospace, automotive, and industrial sectors, the superior thermal, mechanical, and chemical properties of polyimide PCBs justify their use despite higher material and production costs. They enable engineers to design compact, high-performance circuits that remain reliable throughout extended operational life.

High-frequency and high-speed electronic systems place unique demands on PCB materials. Signal integrity, impedance control, and dielectric stability are paramount, and polyimide materials provide significant advantages in these areas.

At gigahertz frequencies, even minor variations in dielectric properties can lead to signal loss or reflection. Polyimide’s stable dielectric constant and lower dissipation factor minimize attenuation, enabling cleaner signal transmission and reducing crosstalk between traces.

Precise impedance control is essential for high-speed communication circuits and RF applications. Polyimide PCBs allow for consistent layer thickness and dielectric performance, ensuring that designed impedance is maintained across the board. This results in fewer transmission errors and improved system reliability.

High-frequency circuits often generate localized hotspots due to dense component placement and high switching speeds. Polyimide’s excellent thermal conductivity and high Tg allow it to dissipate heat efficiently, reducing the risk of thermal degradation that could compromise signal quality.

Polyimide PCBs are widely used in radar systems, 5G infrastructure, satellite communication modules, and high-speed computing platforms. Their combination of thermal stability, mechanical flexibility, and electrical performance makes them a preferred choice for engineers designing next-generation systems.

Polyimide PCBs offer unmatched advantages over traditional FR4 boards, particularly in high-performance, high-reliability, and harsh-environment applications. Their superior thermal stability, mechanical resilience, chemical resistance, and electrical performance make them indispensable for aerospace, automotive, industrial, and high-speed electronics.

While the initial material and production costs are higher, the long-term benefits — reduced maintenance, extended lifespan, and enhanced reliability — justify the investment. Designers seeking to optimize both performance and durability often turn to polyimide PCBs for flexible, rigid, or rigid-flex applications.

High-quality manufacturing and testing are critical to fully realize the benefits of polyimide boards. Companies like JM PCB provide the necessary expertise, infrastructure, and quality control to ensure that these advanced PCBs meet the rigorous demands of modern electronics.

In summary, for engineers aiming to design electronics that withstand extreme conditions, support high-speed communication, and deliver long-term reliability, polyimide PCBs represent a forward-looking, strategic choice.

1. What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

2. Can polyimide PCBs be used in high-frequency applications?

Yes. Polyimide PCBs have a stable dielectric constant and low dissipation factor, which improves signal integrity and reduces signal loss at high frequencies. They are commonly used in RF, microwave, and 5G systems.

3. How do polyimide PCBs compare to FR4 in terms of thermal performance?

Polyimide PCBs have a higher glass transition temperature (Tg) and can operate reliably at temperatures above 250°C, whereas FR4 typically degrades above 130–140°C. Polyimide also maintains dimensional stability under thermal cycling.

4. What are the benefits of using polyimide PCBs in flexible or rigid-flex designs?

Polyimide’s elasticity allows for repeated bending without cracking, making it ideal for wearable devices, foldable electronics, and compact industrial systems. In rigid-flex boards, it bridges rigid sections while distributing mechanical stress evenly.

5. Why choose JM PCB for polyimide PCB manufacturing?

JM PCB offers specialized expertise in polyimide materials, advanced manufacturing capabilities for multilayer and rigid-flex boards, and rigorous quality control. Their solutions ensure high reliability, precise impedance control, and compliance with industry standards.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote