In the rapidly evolving world of high-power electronics, managing heat has become a critical design consideration. Devices such as power amplifiers, LED modules, electric vehicles (EVs), and industrial automation equipment generate substantial heat during operation. If not properly managed, this heat can lead to performance degradation, component failure, and reduced lifespan of the system. This is where Thermal Boards play a vital role.

Thermal Boards are specialized printed circuit boards (PCBs) designed to efficiently transfer heat away from critical components, ensuring operational stability and reliability. Unlike conventional PCBs, which primarily focus on electrical interconnections, Thermal Boards incorporate materials and design techniques specifically aimed at enhancing thermal conductivity.

The importance of thermal management in electronics cannot be overstated. As devices become smaller and more powerful, traditional cooling methods like air convection or simple heat sinks are often insufficient. Thermal Boards address these challenges directly by integrating high-conductivity materials into the PCB itself, reducing thermal resistance, and improving heat dissipation across the entire system.

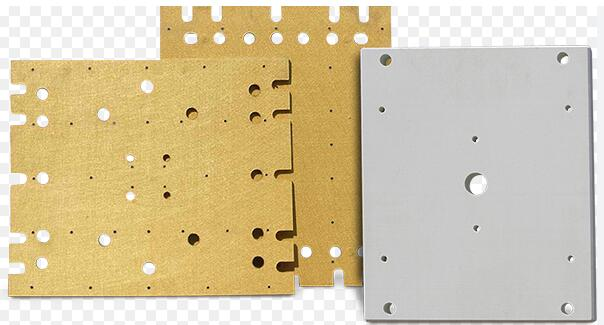

Thermal Boards

The efficiency of a Thermal Board is primarily determined by its material composition and structural design. Key components include:

Copper Layers: Copper is the primary conductor of both electricity and heat in PCBs. In Thermal Boards, thicker copper layers are often used, sometimes exceeding 2 oz/ft² (70 µm), to maximize heat spreading from hotspots.

High-Thermal-Conductivity Substrates: Traditional FR4 substrates have limited thermal conductivity (~0.3–0.4 W/m·K). Thermal Boards often use materials such as aluminum, copper-invar-copper (CIC), or ceramic substrates, which can reach thermal conductivities up to 200 W/m·K. These materials allow for rapid heat transfer away from critical components.

Thermal Vias: To improve heat dissipation from surface-mounted devices (SMDs) to inner or bottom layers, Thermal Boards employ dense arrays of plated through vias filled with copper or thermally conductive epoxy. This technique dramatically reduces localized heat buildup.

Embedded Heat Spreaders: Advanced Thermal Boards sometimes integrate metal cores or embedded heat spreaders directly beneath high-power components. These structures further enhance the board’s ability to move heat away from sensitive areas.

Design principles for Thermal Boards include:

Minimizing thermal resistance: Strategic placement of copper pours and vias ensures heat flows efficiently from components to the board or external heat sinks.

Balancing electrical and thermal requirements: While copper helps dissipate heat, excessive copper can lead to electrical interference or weight issues. Designers must optimize the layout carefully.

Mechanical reliability: Thermal expansion mismatch between different materials can cause warping or cracking. Choosing substrates with compatible coefficients of thermal expansion (CTE) is essential.

Through these techniques, Thermal Boards provide a foundation for high-reliability electronics where heat management is critical.

The benefits of using Thermal Boards in high-power applications are numerous:

Enhanced Thermal Management: By effectively dissipating heat, these boards reduce the risk of overheating and associated component failure. This is particularly crucial in power electronics where temperatures can spike rapidly.

Improved System Reliability: Components operating at lower temperatures generally have longer lifespans. Thermal Boards thus contribute directly to system reliability and reduce maintenance costs.

Compact Design Capabilities: With better heat dissipation, designers can place high-power components closer together without risking thermal stress, allowing for more compact, lightweight designs.

Energy Efficiency: By managing heat effectively, Thermal Boards can reduce the need for additional cooling mechanisms such as fans or large heat sinks, saving energy and reducing noise.

Compatibility with Advanced Electronics: From electric vehicle power modules to LED lighting arrays and 5G infrastructure, Thermal Boards provide the robust foundation required for next-generation technologies.

The manufacturing of Thermal Boards requires precision and careful selection of materials to achieve optimal heat dissipation and electrical performance. Unlike standard PCBs, the process emphasizes thermal conductivity and mechanical reliability.

Material Preparation

High-thermal-conductivity substrates such as aluminum, copper-invar-copper (CIC), or ceramic materials are prepared according to design specifications. Copper foils are chosen based on thickness and type (rolled or electrolytic), influencing both electrical and thermal performance.

Lamination

Layers are bonded together under high pressure and temperature to form a solid board. Advanced thermal laminates ensure strong adhesion between copper layers and substrates, preventing delamination even under high thermal stress.

Circuit Patterning

The copper layer is etched using precision photolithography or dry film processes to form the desired circuit patterns. In Thermal Boards, attention is given to maximizing copper coverage in areas requiring heat dissipation.

Drilling and Via Formation

Thermal vias are drilled using mechanical or laser techniques. These vias are then plated with copper or filled with thermally conductive epoxy to enhance heat transfer from the surface to inner layers.

Surface Finishing

The boards are finished with coatings like ENIG, immersion silver, or HASL. Surface finishes must ensure solderability while maintaining high thermal performance.

Testing and Quality Assurance

Thermal Boards undergo rigorous electrical and thermal testing. Thermal imaging and impedance analysis verify that heat dissipation meets design specifications and that the board can withstand operational stresses.

Insight: The complexity of the manufacturing process highlights why not all PCB suppliers can produce high-quality Thermal Boards. Partnering with experienced manufacturers like JM PCB can ensure reliable and consistent results for demanding applications.

While standard FR4 PCBs excel at electrical interconnection, they are limited in their ability to dissipate heat. Thermal Boards, by contrast, are specifically engineered for heat-intensive applications.

| Feature | Traditional PCB | Thermal Boards |

|---|---|---|

| Substrate | FR4 | Aluminum, CIC, Ceramic |

| Thermal Conductivity | ~0.3–0.4 W/m·K | 20–200 W/m·K |

| Copper Thickness | Standard (1 oz/ft²) | Often ≥2 oz/ft² |

| Heat Dissipation | Limited | Optimized via thermal vias, heat spreaders |

| Reliability in High-Power Applications | Moderate | High |

The difference becomes critical in high-power electronics. Overheating in traditional PCBs can lead to component failure, warping, and system downtime. Thermal Boards mitigate these risks by integrating heat management into the board itself, rather than relying solely on external cooling solutions.

LED Lighting Systems

High-brightness LEDs generate significant heat. Thermal Boards allow for dense LED arrays without overheating, improving light output and lifespan.

Electric Vehicles (EVs)

Powertrain modules in EVs operate under high currents and voltages. Thermal Boards ensure stable performance, reducing the risk of thermal runaway and enhancing safety.

5G Infrastructure

High-frequency, high-power amplifiers in 5G base stations require precise thermal management. Thermal Boards provide consistent thermal paths, maintaining signal integrity and component longevity.

Industrial Automation

Robotic drives and motor controllers generate heat during continuous operation. Thermal Boards prevent localized hotspots and reduce maintenance requirements.

These examples illustrate that integrating Thermal Boards into design not only improves device performance but also enables more compact and efficient system layouts.

Long-term reliability is a core reason designers choose Thermal Boards in high-power electronics. Several strategies can enhance board performance over time:

Thermal Simulation During Design

Using thermal simulation software allows engineers to predict hotspots and optimize copper distribution, thermal vias, and heat spreaders before fabrication. Simulating real-world operational conditions ensures that the Thermal Board will maintain performance throughout its lifecycle.

Material Selection for Stability

Choosing substrates with compatible coefficients of thermal expansion (CTE) reduces the risk of warping or cracking during thermal cycling. Advanced materials such as aluminum-core or ceramic-core substrates provide both thermal conductivity and mechanical stability.

Optimized Via and Pad Layouts

A well-planned arrangement of thermal vias and copper pads improves heat flow while maintaining signal integrity. Spacing, size, and plating thickness of vias are critical parameters for reliable thermal management.

Protective Coatings

Applying protective coatings like conformal coatings or high-temperature solder masks can protect against moisture, dust, and oxidation while maintaining thermal conductivity.

Regular Monitoring in Critical Applications

In high-stakes applications such as EV power modules or industrial robotics, monitoring temperature profiles during operation can provide early warning signs of potential failures, allowing preemptive maintenance and reducing downtime.

Insight: Optimizing Thermal Boards for long-term reliability is not just about materials—it’s also about design foresight and operational monitoring. Boards designed with careful thermal planning often outperform those relying solely on external cooling solutions.

Effective integration of Thermal Boards requires collaboration between electrical, mechanical, and thermal engineers. Key considerations include:

Concurrent Engineering

Thermal, mechanical, and electrical teams should work together from the earliest design stages to ensure heat dissipation strategies align with functional requirements.

Component Placement

High-power components should be strategically located near thermal vias, heat sinks, or embedded spreaders. Minimizing thermal path length reduces localized heat buildup.

Simulation and Prototyping

Prototyping and iterative testing validate thermal performance before mass production. Thermal imaging and impedance analysis help confirm the board meets specifications.

Vendor Collaboration

Partnering with experienced suppliers, such as JM PCB, ensures high-quality fabrication and adherence to tight tolerances, particularly for complex multi-layer Thermal Boards. Supplier expertise can also guide material choices and advanced thermal via strategies.

As electronics evolve, Thermal Boards play a pivotal role in enabling next-generation technologies:

Electric Vehicles (EVs)

Battery management systems and inverters require boards capable of handling high currents while maintaining temperature stability. Thermal Boards help prevent overheating and improve vehicle safety and efficiency.

5G Telecommunications

High-power RF amplifiers and signal processing units generate significant heat. Thermal Boards maintain performance and ensure reliable signal integrity in high-frequency circuits.

Internet of Things (IoT) Devices

IoT modules often have compact form factors with minimal space for conventional heat sinks. Integrating Thermal Boards enables dense layouts without compromising thermal management.

Renewable Energy Systems

Solar inverters, wind turbine controllers, and other renewable energy electronics benefit from Thermal Boards, which reduce thermal stress and extend system lifespan.

Insight: As electronics demand more power in smaller footprints, the integration of Thermal Boards is no longer optional—it’s a necessity for reliable and high-performance design.

While Thermal Boards offer significant advantages for high-power electronics, there are challenges and evolving trends that designers must consider:

Material Costs

High-thermal-conductivity substrates like aluminum, CIC, or ceramic are more expensive than traditional FR4. Designers must balance cost with performance requirements, particularly in large-scale manufacturing.

Complex Manufacturing

The production of Thermal Boards demands precision in lamination, via plating, and surface finishing. Any deviation can compromise thermal performance, leading to hot spots or mechanical stress.

Design Complexity

Integrating thermal vias, heat spreaders, and high-density copper layers requires advanced design skills. Electrical and thermal requirements must be optimized concurrently to avoid trade-offs that could degrade performance.

Reliability under Extreme Conditions

Applications in automotive, aerospace, and industrial automation expose Thermal Boards to wide temperature ranges and mechanical stress. Ensuring long-term reliability in these environments requires meticulous material and layout selection.

Advanced Materials

Research into novel substrates with even higher thermal conductivity and lower thermal expansion is ongoing. Materials like graphene-enhanced composites or hybrid ceramics could redefine Thermal Boards in the next decade.

Embedded Cooling Solutions

Beyond thermal vias and metal cores, future boards may integrate microfluidic channels or phase-change materials for active cooling at the board level.

AI-Driven Thermal Design

Artificial intelligence and machine learning are increasingly used to simulate complex thermal interactions, optimizing board layout, via placement, and component arrangement with unprecedented precision.

Sustainability Focus

As environmental regulations tighten, Thermal Boards with recyclable materials, lower energy-intensive manufacturing, and reduced reliance on metal cores will gain importance.

Miniaturization and High-Density Integration

With devices becoming smaller and more power-dense, Thermal Boards will need to maintain high performance in ever-tighter layouts, supporting innovations like wearable electronics and compact EV modules.

Insight: These trends indicate that Thermal Boards are not static; they are evolving alongside the electronics industry. Designers who stay informed about material innovations, manufacturing techniques, and simulation technologies will maintain a competitive advantage.

Thermal Boards are the backbone of reliable, high-power electronics. They enable efficient heat dissipation, improve system reliability, and support the miniaturization of complex circuits. From LED lighting to electric vehicles, 5G infrastructure, and industrial automation, their role is critical in modern design.

Key Takeaways:

Material and Design Matter: The combination of high-thermal-conductivity substrates, thick copper layers, and optimized thermal vias ensures maximum heat management.

Long-Term Reliability: Proper simulation, protective coatings, and operational monitoring extend device lifespan.

Collaboration is Essential: Integrating Thermal Boards into design workflows requires coordination between thermal, electrical, and mechanical teams.

Future-Proofing: Advanced materials, embedded cooling, AI-assisted design, and sustainability considerations will shape the next generation of Thermal Boards.

FAQ

Q: Are Thermal Boards suitable for high-frequency RF applications?

A: Yes. With careful material selection and layout optimization, Thermal Boards can manage heat without negatively affecting signal integrity, making them suitable for high-frequency applications like 5G.

Q: How do Thermal Boards differ in LED vs power electronics applications?

A: While the underlying thermal management principles are similar, LED applications focus on uniform heat spreading to maintain light output and longevity, whereas power electronics prioritize rapid heat transfer to prevent component overheating and maintain operational reliability.

Q: How do thermal vias improve heat dissipation in Thermal Boards?

A: Thermal vias provide a direct pathway for heat to travel from the surface-mounted components to internal or bottom layers of the PCB. By connecting copper layers through these vias, localized heat is spread more evenly, preventing hotspots.

Q: Can Thermal Boards be used in both low- and high-frequency applications?

A: Yes. While their primary advantage is thermal management, the materials and layout can be optimized for high-frequency signal integrity, making Thermal Boards versatile for a range of electronic applications.

Q: What is the difference between rolled copper foil and electrolytic copper foil?

A: Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote