At its core, Immersion Gold refers to a surface finish applied through a chemical displacement reaction, where gold is deposited over a thin nickel barrier layer. This technique, part of the ENIG (Electroless Nickel Immersion Gold) process, involves immersing the copper pads of a PCB into a gold plating solution that displaces nickel atoms from the surface.

Unlike electroplating, which relies on electrical current, the immersion process is purely chemical, ensuring uniform deposition even on complex geometries. The gold layer is extremely thin (typically between 0.05–0.125 µm), yet it provides powerful resistance to oxidation, corrosion, and environmental degradation. Beneath it lies a 3–6 µm thick electroless nickel layer that serves as both a diffusion barrier and a structural foundation.

The result is a highly stable, flat, and solderable surface — ideal for fine-pitch Ball Grid Array (BGA) packages and other components requiring exceptional planarity. The gold layer protects the nickel from oxidation until the PCB is assembled, where it dissolves into the solder joint, leaving behind the nickel as the primary contact surface.

This precise control over layer chemistry and thickness is what gives Immersion Gold its unique advantage over other finishes. It is not merely decorative; it is a material solution engineered for consistency and precision. The core reason for using an Immersion Gold PCB board lies in its ability to provide an ultra-flat, oxidation-resistant surface that is ideal for fine-pitch components and lead-free soldering processes. Its superior electrical contact reliability and exceptional resistance to tarnish make it particularly suitable for high-performance electronic assemblies that demand precision and longevity.

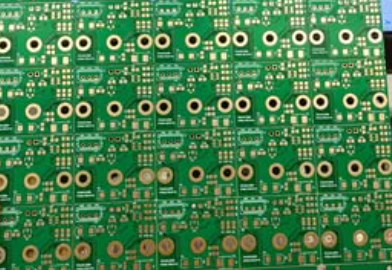

Immersion Gold

The Immersion Gold process follows a carefully managed sequence designed to ensure adhesion, uniformity, and purity of deposited layers. The typical process includes:

Surface Cleaning and Preparation:

Copper pads are cleaned using mild acidic or alkaline solutions to remove oxides, organic residues, and particulates. This ensures the plating chemicals interact directly with the metal surface.

Micro-etching:

A light etching step removes a few micrometers of copper, generating a micro-roughened surface that promotes strong nickel adhesion.

Activation and Electroless Nickel Plating:

A catalytic process initiates the deposition of nickel onto exposed copper areas. This layer acts as a diffusion barrier that prevents copper migration into the solder joint.

Rinse and Gold Immersion:

The nickel-coated PCB is immersed in a gold displacement solution. Nickel atoms are displaced by gold ions, forming a uniform gold coating across the entire pad surface.

Final Rinse and Drying:

The board is rinsed thoroughly and dried in a controlled environment to prevent contamination.

Surface finish selection depends on balancing cost, flatness, reliability, and solder performance. Immersion Gold — part of the broader ENIG process — stands out among alternatives for its flatness and oxidation resistance.

| Surface Finish | Process Type | Flatness | Solderability | Oxidation Resistance | Cost Level | Common Application |

|---|---|---|---|---|---|---|

| HASL (Hot Air Solder Leveling) | Tin-lead or lead-free solder coating | Low | Good | Moderate | Low | Consumer electronics |

| OSP (Organic Solderability Preservative) | Organic chemical layer | High | Good (short-term) | Low | Very Low | Low-cost, single-use PCBs |

| ENEPIG | Nickel + Palladium + Gold layers | Excellent | Excellent | Very High | High | High-reliability boards |

| Immersion Gold (ENIG) | Nickel + Gold | Excellent | Excellent | High | Medium | HDI, BGA, fine-pitch circuits |

The distinguishing feature of Immersion Gold is its flat, non-bridging surface, critical for automated assembly processes. Its planarity ensures solder paste deposition is consistent, which translates into higher yield rates and fewer open circuits.

While its cost is higher than OSP or HASL, it often pays for itself through improved assembly efficiency, rework reduction, and extended shelf life.

The structural integrity of an Immersion Gold finish relies on the interaction between its two main metallic layers — nickel and gold. The nickel layer serves as the functional barrier, preventing copper migration and forming the actual solder joint interface. The gold layer primarily acts as a protective coating to shield nickel from oxidation.

The nickel is deposited electrolessly, meaning no external current is required. Instead, it relies on a catalytic chemical reaction that ensures even coating on all exposed surfaces. This step is vital; any non-uniformity can compromise solderability and lead to mechanical weaknesses.

The immersion gold process then forms a thin gold layer via displacement — nickel atoms dissolve slightly while gold ions are reduced, forming a controlled, dense metallic film. The chemistry must be meticulously balanced; excess gold thickness adds unnecessary cost and can cause solder wetting issues, while insufficient thickness risks oxidation.

The interface between gold, nickel, and copper in an Immersion Gold PCB is more than a physical boundary — it’s a series of controlled metallurgical reactions. At the nickel-gold boundary, a complex intermetallic layer forms that enhances adhesion while preventing diffusion of base metals.

During soldering, the gold layer dissolves rapidly into molten solder, exposing the nickel, which forms a stable nickel-tin intermetallic compound. This provides a mechanically strong and corrosion-resistant joint. The thin gold layer’s dissolution is essential; if too thick, residual gold can create brittle AuSn4 compounds, reducing joint integrity.

This balance of thickness and chemistry defines the performance of an Immersion Gold surface. Controlled dissolution ensures excellent solder flow and joint reliability without compromising conductivity.

Planarity is one of the most celebrated benefits of Immersion Gold. Unlike HASL finishes that produce uneven surfaces due to molten solder leveling, Immersion Gold results in a near-mirror-flat coating. This flatness is crucial for Surface Mount Technology (SMT), especially Ball Grid Array (BGA), Chip Scale Packages (CSP), and fine-pitch ICs, where even micrometer-level unevenness can cause alignment or soldering defects.

The process ensures that solder paste deposition through stencils is consistent, minimizing bridging and tombstoning. Moreover, it supports reliable reflow soldering under lead-free conditions, where temperature profiles are tighter and wetting windows narrower.

In reliability testing, PCBs with Immersion Gold consistently show fewer solder joint defects and higher bonding strength over multiple thermal cycles. The flat surface also improves automated optical inspection (AOI) accuracy, as the reflectivity and uniformity help machine vision systems detect anomalies more precisely.

The cost of implementing an Immersion Gold finish in PCB production is often misunderstood. While many assume that gold itself is the primary cost driver, the reality is more nuanced. The overall cost of Immersion Gold depends on a combination of raw material prices, chemical process control, equipment precision, and plating yield efficiency.

Gold, being a precious metal, does contribute to the base material cost, but since the deposited layer is incredibly thin—typically around 0.05 to 0.125 micrometers—its direct contribution to total cost is relatively minor compared to the cost of maintaining chemical stability, nickel bath longevity, and process consistency.

In advanced production lines such as those at JM PCB, efficiency is achieved through bath regeneration systems, inline filtration, and automated chemical monitoring. These controls minimize waste and optimize gold usage, allowing Immersion Gold to remain cost-effective even in high-volume production environments.

The cost-per-board also depends on factors such as:

Board area covered with pads and exposed copper.

Number of surface finishes per production batch.

Thickness and uniformity of nickel and gold layers.

Maintenance cost of plating tanks and chemical replenishment.

Yield rate (since defects like black pad increase rework costs).

Thus, the economics of Immersion Gold aren’t defined solely by metal price but by process yield and precision. A manufacturer with consistent quality control—like JM PCB—can deliver Immersion Gold PCBs with both competitive cost and premium performance.

When calculating total fabrication costs, Immersion Gold adds an incremental expense over lower-cost finishes like OSP or HASL. However, this modest cost increase can lead to substantial downstream savings in assembly, reliability, and maintenance.

Let’s consider how Immersion Gold impacts the overall cost chain:

| Cost Category | Impact of Immersion Gold | Description |

|---|---|---|

| Material Cost | Moderate | Nickel and gold add to raw material expenses but are used in micro-thickness layers. |

| Process Control | High Importance | Tight monitoring is required to prevent black pad or contamination. |

| Assembly Yield | Improved | Flat surface ensures accurate stencil printing and solder paste volume. |

| Rework/Repair Cost | Reduced | Stronger and cleaner joints minimize defects and rework frequency. |

| Lifecycle Cost | Lower | Enhanced corrosion resistance prolongs product lifespan. |

The net result is that Immersion Gold pays for itself over the product’s life cycle. Products requiring precise solderability—such as high-speed communication devices, medical electronics, or military-grade boards—benefit immensely from reduced assembly failure rates.

Manufacturers who ignore this aspect often face higher hidden costs later in rework, warranty claims, or early field failures. From a total cost of ownership (TCO) perspective, Immersion Gold is one of the most cost-efficient solutions for premium-grade PCBs.

Not every project demands Immersion Gold, but when flatness, reliability, and oxidation resistance are critical, it becomes an indispensable investment. Projects with fine-pitch BGAs, high-frequency RF designs, or lead-free soldering environments particularly benefit.

When making the cost-performance decision, engineers should consider the following factors:

Component Density: The tighter the pitch, the greater the benefit of Immersion Gold flatness.

Storage and Shelf Life: Immersion Gold PCBs can be stored longer without oxidation compared to OSP.

Environment: For high-humidity or corrosive conditions, gold’s inert nature ensures stability.

Reflow Conditions: The finish withstands multiple soldering cycles without degradation.

In short, Immersion Gold’s value becomes apparent in high-reliability applications where any deviation in solderability could cause catastrophic failure. The additional cost, when spread over yield improvement and long-term stability, is negligible compared to the potential risk avoided.

One of the defining attributes of Immersion Gold is its exceptional electrical contact stability. The gold layer, though thin, provides a surface that resists oxidation and maintains low contact resistance over time. This is crucial for signal integrity, particularly in high-frequency circuits and analog applications where even micro-ohm variations can affect performance.

Because gold is a noble metal, it doesn’t react with oxygen or moisture, ensuring that electrical contacts remain clean and conductive for years. The underlying nickel layer also contributes by acting as a reliable current-carrying path once the gold is dissolved during soldering.

Comparatively, finishes like HASL or OSP can experience micro-oxidation or uneven deposition, resulting in unreliable solder joints or impedance fluctuations. Immersion Gold eliminates this uncertainty, providing designers with a consistent and predictable electrical interface.

Solderability is where Immersion Gold truly distinguishes itself. Because its surface remains flat, clean, and oxidation-free, it facilitates superior wetting during solder reflow. The solder spreads evenly across pads, forming strong and uniform joints.

This property becomes especially valuable in lead-free soldering, which operates at higher temperatures and demands narrower process margins. Immersion Gold’s stable surface ensures that even after prolonged storage or multiple reflow cycles, the solderability remains excellent.

Oxidation resistance is another major strength. Traditional copper or tin surfaces begin to oxidize soon after exposure to air, complicating assembly if delayed. In contrast, gold remains inert, protecting the nickel layer underneath for months. This translates into greater flexibility in production scheduling and inventory management.

Tests have shown that Immersion Gold PCBs maintain reliable solderability for over 12 months when stored in proper conditions, significantly reducing material wastage.

Reliability testing consistently demonstrates that Immersion Gold enhances a PCB’s mechanical and thermal performance. The nickel layer contributes most of the mechanical robustness by providing a hard and stable base, while the gold layer prevents oxidation that could weaken the solder interface.

Under thermal cycling—repeated heating and cooling that simulate operating conditions—Immersion Gold boards exhibit less joint cracking, peeling, and delamination compared to HASL or OSP finishes. The uniform layer adhesion ensures that stress is evenly distributed, extending the board’s fatigue life.

Additionally, the coefficient of thermal expansion (CTE) between nickel and copper is compatible, minimizing warpage during reflow. This mechanical harmony is critical for BGA packages, where even slight deformation can lead to open connections.

From an engineering standpoint, the Immersion Gold process creates a balanced surface system — strong, flat, and thermally stable — capable of meeting the rigorous demands of high-density interconnects (HDI), rigid-flex designs, and 5G communication modules.

The term “flatness” may seem trivial, but in modern electronics, it is the difference between a flawless assembly and a production failure. Immersion Gold delivers industry-leading planarity, essential for fine-pitch and ultra-fine-pitch components.

When stencil printing solder paste, even a microscopic height variation can cause insufficient paste deposition or bridging. Immersion Gold’s surface flatness ensures uniform paste transfer, resulting in consistent solder joints. For BGA or CSP packages, where ball alignment tolerances are measured in microns, this is a decisive advantage.

Moreover, the absence of solder “peaks” or “valleys” seen in HASL finishes allows for more precise automated optical inspection (AOI) and X-ray verification. The smooth surface reflects light uniformly, helping inspection systems detect defects more accurately.

In high-speed and high-frequency applications, surface finish can directly influence signal quality. Any surface roughness or non-uniform plating can cause micro-reflections and impedance mismatch, leading to signal attenuation.

Immersion Gold, with its smooth, continuous coating, minimizes such inconsistencies. The combination of gold’s conductivity and nickel’s stability creates a low-loss pathway for high-frequency signals. This is particularly critical in 5G communication, radar systems, and RF front-end modules, where even minor loss translates to measurable performance degradation.

The protective gold layer also prevents surface corrosion, which could otherwise introduce micro-pitting and affect signal transmission. Over time, Immersion Gold preserves signal clarity by ensuring the interconnect interface remains smooth, conductive, and uncontaminated.

When engineers weigh the merits of Immersion Gold against other high-end finishes like ENEPIG, the comparison often revolves around reliability, cost, and soldering performance. Both are multi-layered metallic finishes that utilize nickel as a barrier layer, but ENEPIG introduces an additional palladium layer between nickel and gold. This small modification dramatically affects the surface’s properties.

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) offers even higher corrosion resistance and superior wire bonding capability, particularly beneficial for applications involving both soldering and gold wire bonding. However, the inclusion of palladium significantly increases the process cost and complexity.

In contrast, Immersion Gold provides an optimal balance — achieving excellent solderability and flatness at a more reasonable cost. For most SMT applications where wire bonding is not required, Immersion Gold’s performance is nearly indistinguishable from ENEPIG.

| Property | Immersion Gold | ENEPIG |

|---|---|---|

| Solderability | Excellent | Excellent |

| Wire Bonding Compatibility | Limited | Excellent |

| Corrosion Resistance | High | Very High |

| Process Cost | Medium | High |

| Typical Use | SMT, BGA, HDI | Hybrid solder/wire bond applications |

For high-volume consumer or industrial boards, Immersion Gold remains the preferred solution because its cost-performance ratio outshines ENEPIG in environments where cost control is as important as reliability.

OSP, or Organic Solderability Preservative, is among the most cost-effective surface finishes used in PCB fabrication. It coats exposed copper with an organic compound that prevents oxidation prior to soldering. However, the protection offered by OSP is temporary and fragile.

In contrast, Immersion Gold delivers long-term oxidation resistance and mechanical stability that OSP cannot match. OSP’s thin organic coating degrades with exposure to humidity, temperature, or even handling, making it suitable only for short-term use and single reflow cycles.

Immersion Gold, with its metallic barrier layers, maintains its integrity across multiple soldering operations and extended storage periods. It also provides a much flatter surface, allowing for more precise assembly processes.

| Attribute | OSP | Immersion Gold |

|---|---|---|

| Cost | Very Low | Medium |

| Flatness | Excellent | Excellent |

| Durability | Low | High |

| Oxidation Resistance | Weak | Strong |

| Multi-Reflow Capability | Poor | Excellent |

While OSP has its place in low-cost consumer products, Immersion Gold is indispensable for high-reliability designs where extended life and environmental resilience are essential.

HASL was once the industry’s dominant surface finish, primarily due to its simplicity and low cost. It involves coating the PCB with molten solder and using hot air to remove excess solder. However, its fundamental limitation is surface unevenness.

In contrast, Immersion Gold produces a perfectly flat surface, critical for fine-pitch components, BGAs, and HDI boards. The HASL process often leaves small peaks and valleys of solder, making it unsuitable for high-density layouts or miniature components.

Furthermore, HASL can introduce thermal stress to the PCB due to the high temperatures involved, potentially warping thin substrates. Immersion Gold avoids this issue through a low-temperature chemical process that is gentler on materials.

| Property | HASL | Immersion Gold |

|---|---|---|

| Surface Flatness | Poor | Excellent |

| Suitable for Fine-Pitch | No | Yes |

| Lead-Free Compatibility | Yes (LF-HASL) | Yes |

| Process Temperature | High | Moderate |

| Oxidation Resistance | Moderate | High |

Thus, while HASL remains viable for basic applications, the demands of modern electronics—especially in RF, aerospace, and automotive fields—have pushed manufacturers to adopt Immersion Gold as a superior alternative.

To fully exploit the benefits of Immersion Gold, PCB designers must understand how pad geometry, trace width, and solder mask alignment influence plating results. Because the gold layer is only a few tens of nanometers thick, uniform nickel distribution beneath it is crucial to ensure consistent solderability and bond strength.

Designers should avoid excessively large copper exposure areas, as these can increase plating time and affect thickness uniformity. Similarly, close pad spacing—common in BGA or QFN layouts—requires precise solder mask definition to prevent plating bridging or uneven deposition.

Key recommendations include:

Maintain consistent pad dimensions across identical components to ensure plating uniformity.

Use solder mask-defined pads only when absolutely necessary; otherwise, prefer non-solder mask-defined (NSMD) pads for better solder joint reliability.

Keep trace-to-pad spacing sufficient to avoid capillary effects during immersion plating.

By integrating these design principles, engineers can achieve optimal Immersion Gold coating quality, leading to both enhanced flatness and superior electrical performance.

The layout density of copper pads directly impacts plating uniformity. Dense copper regions consume more chemical reactants during the nickel and gold deposition processes, resulting in local thickness variations. Advanced manufacturers like JM PCB employ automated bath replenishment systems that maintain chemical balance and ensure even gold coverage across all board areas.

From a design perspective, distributing exposed copper areas evenly helps maintain chemical equilibrium during immersion. Designers should also consider adding dummy pads or thieving patterns in sparse regions to promote plating consistency.

This proactive design approach enhances both flatness and reliability, as uniform layer thickness reduces the risk of partial oxidation or inconsistent solderability.

Quality assurance is an essential step in confirming that Immersion Gold layers meet both dimensional and electrical standards. Flatness, layer thickness, and surface contamination are commonly evaluated through multiple analytical techniques:

X-Ray Fluorescence (XRF) Testing: Measures the thickness and uniformity of both nickel and gold layers.

Atomic Force Microscopy (AFM): Evaluates surface roughness at the nanometer scale to verify flatness.

Cross-Sectional Analysis: Reveals layer integrity, adhesion, and any micro-voids at the nickel-gold interface.

Solderability Tests: Assess wetting time and spread under standard reflow conditions.

In high-quality facilities such as JM PCB, these inspections are integrated into automated quality control systems. The company’s real-time feedback loops allow immediate process adjustments if measurements deviate from specification. This precision-driven approach not only ensures compliance with IPC Class 3 standards but also reinforces the long-term reliability of every Immersion Gold PCB produced.

Traditional metal finishing processes have often been associated with environmental risks due to the use of toxic chemicals and heavy metals. However, the modern Immersion Gold process has evolved toward sustainability. Manufacturers now utilize cyanide-free gold solutions, closed-loop wastewater recycling, and low-phosphorus electroless nickel chemistry to minimize waste and pollution.

Leading producers like JM PCB implement advanced waste treatment systems that neutralize metal ions before discharge. Recovered gold residues are filtered and refined, ensuring nearly zero material loss and minimal environmental impact.

The shift toward green chemistry has also improved workplace safety. Lower pH gold baths and non-toxic reducing agents have replaced older, hazardous compounds, aligning Immersion Gold production with global environmental standards such as RoHS, REACH, and ISO 14001.

The nickel barrier beneath the gold in Immersion Gold PCBs plays a vital role in corrosion resistance. Without this barrier, copper atoms would diffuse into the gold layer over time, leading to discoloration and performance degradation.

The electroless nickel layer not only prevents diffusion but also provides mechanical hardness that enhances wear resistance during repeated connector insertions. In applications like industrial automation and aerospace connectors, this feature ensures signal integrity under harsh environmental stress.

Furthermore, by controlling phosphorus content in the nickel layer—typically between 5% and 9%—manufacturers can optimize corrosion performance. Low-phosphorus nickel provides superior hardness, while mid-phosphorus formulations balance corrosion protection and ductility.

Maintaining process consistency in Immersion Gold fabrication requires rigorous quality control. Key parameters include bath pH, temperature, immersion time, and chemical concentration. Even minor deviations can alter plating thickness or lead to defects like black pad formation.

To prevent such issues, manufacturers employ inline monitoring systems that continuously analyze bath composition. Regular XRF verification ensures that nickel and gold layers meet precise thickness targets. Surface roughness metrics, measured via AFM, confirm that planarity is within tolerance for fine-pitch applications.

The decision to use Immersion Gold is not solely based on technical merit but also on economic justification. For high-density interconnect (HDI) designs, BGA packages, and multilayer boards, the surface finish cost represents a small fraction of the total fabrication expense, yet it directly influences assembly yield and long-term reliability.

Immersion Gold typically costs more than HASL or OSP due to the precious metal involved, but it offers significant returns in reduced rework, longer storage life, and higher electrical integrity. For products with high reliability requirements—such as industrial control systems or 5G communication devices—the value proposition is clear: Immersion Gold minimizes production variability and post-assembly failure rates.

In addition, the smoother surface of Immersion Gold improves solder paste stencil printing accuracy, reducing material waste. The long-term ROI also extends to product maintenance and warranty costs, where consistent performance and durability result in fewer customer returns and extended service intervals.

HDI boards require microvias, fine lines, and precise solder joint control. In such contexts, the cost of an imperfect surface finish can far exceed the incremental price of Immersion Gold. Even a minor flatness defect can cause open circuits or misalignment in BGA pads, leading to rework costs that outweigh the savings from cheaper surface treatments.

Economically, Immersion Gold finds its sweet spot in medium to high-volume production where yield and process stability are critical. Manufacturers often report that the additional 3–5% cost in surface finishing pays back several times over in assembly efficiency and product reliability. Thus, for many OEMs, Immersion Gold is no longer viewed as a premium option but as a cost-optimized standard.

From its precise chemical process to its unmatched surface flatness, Immersion Gold remains one of the most sophisticated and reliable PCB surface finishes available today. Its advantages extend beyond appearance — it enhances solderability, improves corrosion resistance, stabilizes electrical performance, and ensures long-term durability.

While its cost is marginally higher than traditional finishes, the return on investment in assembly yield, product reliability, and lifespan justifies the choice for high-end electronics. Industries ranging from aerospace and telecommunications to automotive and consumer devices have standardized Immersion Gold as their trusted solution for performance consistency.

Furthermore, advancements in eco-friendly chemistry and process automation are making Immersion Gold more accessible and sustainable. Manufacturers like JM PCB exemplify this evolution, combining cost-efficient production with uncompromising quality control. Their expertise ensures that every Immersion Gold PCB delivers the flatness, reliability, and performance that modern electronic design demands.

In an industry where every micron matters, Immersion Gold continues to define excellence — a surface finish that not only meets technical standards but shapes the reliability legacy of tomorrow’s electronic innovations.

1. How does Immersion Gold compare environmentally with lead-free HASL?

Immersion Gold uses chemical displacement rather than molten solder, eliminating lead exposure and minimizing waste. With modern cyanide-free chemistry and closed-loop wastewater systems, it is now one of the most environmentally sustainable surface finishes in PCB manufacturing.

2. Why is Immersion Gold preferred for fine-pitch BGA and SMT assemblies?

Because of its superior flatness and oxidation resistance, Immersion Gold provides a smooth, uniform surface that supports precise solder paste printing and reliable solder joint formation for dense components.

3. Does Immersion Gold affect impedance or signal transmission speed?

No, Immersion Gold layers are extremely thin and have negligible impact on signal impedance. In fact, the stable nickel-gold interface ensures consistent signal transmission by preventing copper oxidation.

4. How long can an Immersion Gold PCB be stored before assembly?

When properly packaged and stored in a dry environment, Immersion Gold PCBs can maintain solderability for more than 12 months — significantly longer than OSP or tin finishes.

5. What are the common failure modes in Immersion Gold plating and how can they be prevented?

Potential issues include “black pad” corrosion, nickel oxidation, or uneven gold thickness. Preventive measures include strict bath control, correct temperature management, and frequent chemical replenishment.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote