In the intricate ecosystem of printed circuit board (PCB) manufacturing, where each layer, trace, and microvia contributes to the final product’s electrical and mechanical reliability, even microscopic surface anomalies can compromise long-term performance. Among these subtle yet destructive defects, few have generated as much industry concern as the Black Pad phenomenon. Though invisible to the naked eye during early production stages, this metallurgical failure mode has proven to be a silent saboteur of solder joint integrity and overall circuit functionality.

The term “Black Pad” refers to a specific corrosion-related defect that occurs during the Electroless Nickel/Immersion Gold (ENIG) surface finishing process. While ENIG has long been celebrated for its exceptional solderability, planarity, and oxidation resistance, its multi-step chemical sequence presents vulnerabilities that—if not carefully managed—can result in a dark, brittle intermetallic layer between the nickel and gold deposits. This compromised interface ultimately causes solder joint fractures, intermittent connections, and premature field failures.

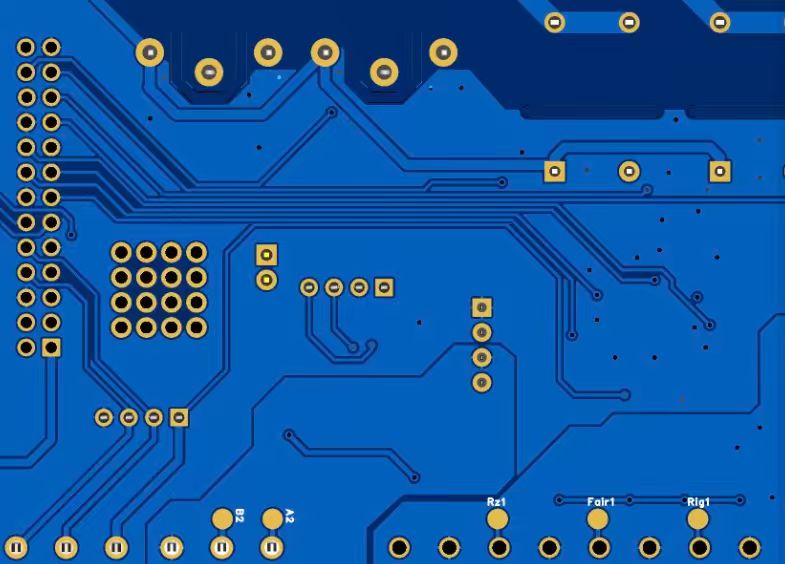

The significance of understanding and controlling this defect cannot be overstated. As PCBs become more complex and miniaturized, the demand for flawless interconnect reliability escalates. In high-reliability applications—such as aerospace systems, automotive electronics, and medical instrumentation—the presence of Black Pad can mean the difference between operational excellence and catastrophic failure.

This comprehensive analysis will explore the Black Pad phenomenon from every relevant angle: its formation mechanisms, the underlying chemistry, contributing process factors, detection techniques, preventive measures, and real-world case studies. The goal is not merely to describe the problem but to empower engineers, quality managers, and PCB manufacturers with practical strategies to anticipate and eliminate it.

Black Pad

To address any failure mechanism effectively, one must first understand its nature at both the physical and chemical levels. The Black Pad phenomenon is essentially a manifestation of nickel surface corrosion that occurs during the immersion gold phase of the ENIG finishing process.

The ENIG process consists of two primary stages:

Electroless Nickel Deposition:

A layer of nickel is deposited onto the copper circuitry without electrical current. The nickel acts as a diffusion barrier, preventing copper migration into the gold layer and serving as the primary solderable surface.

Immersion Gold Deposition:

A thin layer of gold is applied by immersion displacement reaction. The gold protects the underlying nickel from oxidation until soldering occurs.

In a properly controlled process, these layers form a smooth, uniform interface. However, when the chemical balance in the plating baths or surface preparation steps deviates from optimal conditions, microscopic corrosion sites begin to form on the nickel surface. These corroded regions exhibit a dark, often spiky appearance when viewed under a scanning electron microscope—hence the term “Black Pad.”

The hallmark of the defect is the presence of:

Darkened nickel surface zones, often with non-uniform reflectivity.

Phosphorous-enriched intermetallic layers that form brittle boundaries.

Crystalline nodules or spikes that disrupt solder wetting.

Weak solder joints, especially noticeable after thermal cycling or mechanical stress.

Though the affected pads might appear visually acceptable to the unaided eye, their microstructure tells a different story—one of chemical imbalance and premature degradation.

The electrical and mechanical consequences of Black Pad cannot be ignored:

Reduced solder joint strength, often leading to cracks during reflow or vibration.

Intermittent electrical contact, causing unreliable circuit operation.

Accelerated aging, particularly in high-humidity or high-temperature environments.

Quality losses, resulting in costly rework and reduced customer confidence.

Given the subtlety of its appearance, Black Pad often escapes detection until final testing or field deployment—by which time the financial and reputational cost is significantly higher. Understanding the early indicators and root chemistry of the defect is therefore vital.

At its core, the Black Pad phenomenon arises from electroless nickel corrosion induced by improper gold plating chemistry. The reaction that deposits gold from an immersion bath is a galvanic displacement process—gold ions are reduced while nickel atoms are oxidized. This oxidation must occur in a controlled, self-limiting manner. When control is lost, excessive nickel corrosion occurs, leading to the formation of a non-uniform, phosphorous-rich layer that cannot support reliable solder bonding.

During electroless nickel deposition, a reducing agent (commonly sodium hypophosphite) is used. This introduces phosphorous into the nickel matrix, typically ranging from 7–10% by weight. The phosphorous content plays a dual role:

Moderate amounts enhance corrosion resistance.

Excessive content can lead to non-uniform microstructures and stress fractures during thermal cycling.

When the nickel is exposed to the gold bath, the gold ions (Au³⁺) react with nickel atoms, releasing Ni²⁺ ions into the solution. If the immersion gold bath has excessive acidity, high gold concentration, or poor agitation, the nickel dissolution becomes uneven, forming deep pitting. These pits become initiation points for interfacial failure—what is microscopically observed as “Black Pad.”

Contaminants such as sulfur, chloride, or degraded organic stabilizers can exacerbate the reaction imbalance. Sulfur, for instance, catalyzes local nickel corrosion, accelerating the formation of spike-like structures under the gold layer. This spiky morphology traps flux residues and voids during soldering, further compromising adhesion.

From a metallurgical perspective, the interface between the solder and nickel should ideally form a Ni-Sn intermetallic compound (IMC) of controlled thickness. Black Pad distorts this equilibrium, producing:

Discontinuous IMC formation, which leads to weak adhesion.

Brittle fracture paths, especially under mechanical stress.

Increased contact resistance, reducing electrical performance.

The rate of nickel dissolution and gold deposition depends on temperature, pH, and gold ion concentration. Thermodynamically, the reaction favors gold reduction, but kinetically, it can spiral out of control if activation energy thresholds are altered by contaminants or temperature fluctuations. Once the reaction becomes locally aggressive, corrosion spikes propagate faster than they can be passivated.

Understanding this balance of thermodynamics and kinetics is essential for manufacturers who wish to maintain stable ENIG processes. Advanced simulation models are now being used by forward-thinking PCB suppliers, such as JM PCB, to predict the onset of these failure modes and apply automated chemical controls that prevent out-of-spec conditions.

The reliability impact of Black Pad is most evident after the PCB enters real-world service environments. While initial solder joints might appear acceptable post-reflow, latent defects often emerge under operational stress.

Solder joints over Black Pad regions exhibit poor wetting and brittle intermetallic bonding. Under mechanical vibration, thermal cycling, or flexural stress, these joints tend to crack along the weakened nickel interface. This manifests as:

Intermittent open circuits, particularly in fine-pitch components.

Solder ball detachment during BGA or CSP reflow.

Reduced fatigue life under dynamic loading.

Because the corrosion layer introduces a discontinuous conductive path, resistance fluctuations can occur during current flow. In high-speed or high-frequency applications, even slight impedance changes can result in signal degradation, timing errors, or EMI issues.

Black Pad-affected interfaces are more susceptible to moisture ingress. Over time, this accelerates corrosion propagation, resulting in darkened solder joints or complete pad lift-off in extreme cases. For PCBs operating in harsh environments—automotive engine bays, outdoor telecom systems, or aerospace electronics—the risk compounds rapidly.

From a business standpoint, the cost of field failures due to Black Pad is substantial:

Warranty claims from defective assemblies.

Customer dissatisfaction and reputation damage.

Increased inspection and rework costs.

Delays in new product introductions due to reliability concerns.

Thus, Black Pad is not just a metallurgical issue—it’s a reliability, financial, and brand integrity problem that modern manufacturers cannot afford to ignore.

Detecting Black Pad before a board enters assembly is among the most challenging yet critical tasks in PCB quality assurance. Because the defect occurs at a microscopic interfacial level, it often escapes visual inspection or standard optical testing. Nonetheless, there are distinct physical and metallurgical clues that can alert process engineers to potential risks before catastrophic failures occur.

At first glance, a surface afflicted by Black Pad may appear normal or only slightly duller than a well-plated pad. The gold layer typically conceals the underlying nickel corrosion. However, subtle signs include:

A non-uniform gold color tone, ranging from slightly brownish to grayish hues.

Pitted or matte textures instead of the expected mirror finish.

Spotted reflectivity, visible under angled lighting inspection.

Unfortunately, these indicators are not always reliable or consistent. Many Black Pad occurrences present no clear optical symptoms at all, emphasizing the need for more advanced diagnostic methods.

To confirm the presence of the defect, metallographic cross-sectioning is employed. Under scanning electron microscopy (SEM) or optical microscopy, engineers look for:

Darkened, spiky features at the nickel–gold interface.

Porous or uneven nickel boundaries.

High phosphorous concentrations detected through energy-dispersive X-ray spectroscopy (EDX) mapping.

The dark discoloration, which inspired the name “Black Pad,” is primarily due to light scattering caused by the rough, corroded nickel surface.

Solder wetting balance tests provide a functional perspective on the problem. Boards affected by Black Pad exhibit:

Delayed wetting time.

Lower wetting force.

Inconsistent solder spread on identical pads.

Comparative testing against control samples can quantify solderability degradation, allowing manufacturers to trace back process deviations.

More advanced reliability diagnostics, such as thermal shock testing, intermetallic bond strength testing, and contact resistance measurement, can identify subtle joint weaknesses linked to early-stage Black Pad formation. When correlated with process data, these test results form a predictive reliability model.

Through continuous data collection, well-managed production facilities can establish thresholds for bath chemistry, plating rates, and pH levels that correspond to defect-free outcomes. This data-driven approach is one of the key reasons manufacturers like JM PCB have achieved consistent ENIG quality and minimized the risk of latent corrosion defects.

Given the complex and often hidden nature of Black Pad, detection requires a combination of chemical, metallurgical, and electrical testing. The most effective strategy is a layered analytical approach, in which multiple complementary methods are used to build a complete failure picture.

SEM offers high-resolution imaging of the pad surface and cross-section, enabling direct visualization of spiky corrosion features. When combined with EDX elemental mapping, it provides valuable insight into phosphorous enrichment and gold–nickel interface morphology.

AES is one of the most sensitive surface analysis tools for detecting thin oxide films or contamination layers on nickel. It can differentiate between nickel oxide, nickel phosphide, and sulfide compounds—each indicating a different corrosion pathway.

XPS quantifies the chemical state of the elements present in the corroded layer. It is particularly useful for determining the oxidation state of nickel and evaluating the degree of gold displacement reaction.

EIS evaluates the corrosion resistance of the plated surface in situ, allowing manufacturers to assess the protective behavior of the nickel layer without destructive sampling. It measures charge-transfer resistance and can detect subtle changes in corrosion potential indicative of early Black Pad development.

When these analyses are combined, engineers can identify:

The extent of nickel corrosion.

The distribution of phosphorous content.

The gold thickness uniformity.

The correlation between bath chemistry parameters and microstructural outcomes.

By implementing such multi-method testing, companies can transition from reactive troubleshooting to proactive process control, ensuring consistent ENIG surface integrity and minimizing downstream defects.

To eliminate Black Pad, one must address its origins. Root cause analysis reveals that it stems from a chain of chemical and process-related factors rather than a single error. Understanding these interlinked causes allows engineers to build a preventive strategy based on scientific principles rather than reactive measures.

During immersion gold plating, the reduction of gold ions (Au³⁺) is directly coupled with the oxidation of nickel atoms. Ideally, the reaction self-terminates once a monolayer of gold forms. However, when the bath chemistry is off balance—too acidic, too high in gold concentration, or contaminated—the reaction becomes aggressive and continues attacking the nickel layer. This uncontrolled corrosion generates porous and spiky surfaces, typical of Black Pad.

The electroless nickel bath uses sodium hypophosphite as a reducing agent. If boards are insufficiently rinsed before entering the gold bath, residual hypophosphite accelerates nickel dissolution, resulting in localized high-phosphorous nodules and poor solderability.

Over time, nickel baths accumulate by-products such as phosphite ions and organic stabilizer breakdown residues. These contaminants alter deposition kinetics, causing rough nickel surfaces that are highly susceptible to corrosion during the gold immersion stage.

Copper surfaces must be properly micro-etched and cleaned before nickel deposition. Any remaining oxide, organic residue, or moisture can cause non-uniform current density and lead to porous nickel layers. These micro-defects later act as corrosion initiators under the gold layer.

The kinetics of both nickel and gold deposition are sensitive to temperature and pH variations. Even small deviations can shift the balance between uniform deposition and aggressive corrosion. Real-time monitoring and automated chemical control systems are therefore critical in preventing process drift.

In short, Black Pad arises not from one failure but from a chain reaction of process mismanagement, bath contamination, and insufficient quality control. It exemplifies how high-reliability PCB manufacturing requires both chemical expertise and disciplined procedural execution.

Once the mechanisms are understood, prevention becomes a matter of precise process management. Industry experience shows that Black Pad can be effectively mitigated—or even eliminated—through rigorous control of chemical, mechanical, and environmental parameters during ENIG plating.

Maintain phosphorous levels between 7–9% to balance corrosion resistance and solderability.

Regularly analyze the bath for by-product accumulation and replenish as needed.

Implement filtration and agitation systems to ensure homogeneity.

Replace the bath after a defined metal turnover threshold, typically 6–8 cycles.

Proper rinsing after the nickel stage is critical. Multiple cascade rinse tanks with deionized water prevent cross-contamination between nickel and gold baths. Rinse conductivity should remain below 50 µS/cm to minimize chemical carryover.

Maintain pH between 4.0 and 4.6, depending on formulation.

Control temperature precisely—typically between 80–85°C.

Limit gold ion concentration to avoid excessive nickel attack.

Add stabilizers or complexing agents as recommended by chemistry suppliers.

Corrosion of equipment components can introduce metallic impurities that destabilize plating baths. Using corrosion-resistant materials such as PVDF or polypropylene for tanks, and performing regular preventive maintenance, reduces the risk of contamination.

Human error often contributes to bath imbalance. Comprehensive training, standardized work instructions, and digital tracking systems ensure process repeatability and accountability.

SPC provides early warning of trends before defects manifest. Parameters such as plating rate, pH, temperature, and solution potential should be continuously logged and analyzed. Automated systems, like those implemented by JM PCB, use predictive analytics to flag deviations that could trigger Black Pad formation.

Beyond chemical control, the choice of materials and pre-treatment methods significantly influences susceptibility to Black Pad. Optimizing substrate, copper foil, and plating chemistry compatibility enhances robustness throughout the ENIG process.

The base copper’s microstructure directly affects nickel adhesion and uniformity. Rolled copper foil, for instance, offers a smoother, denser grain structure than electrolytic copper foil, resulting in improved nickel coverage and reduced micro-voids. While more expensive, rolled foil can be a strategic choice for high-reliability boards.

Micro-etching removes oxide films and activates the copper surface. Consistent control of etch depth (typically 0.5–1.0 µm) ensures that nickel deposition begins on a fresh, uniform surface. Post-cleaning with deionized water and neutralizers eliminates residual chloride or organic films that can initiate corrosion.

Maintaining gold thickness between 1.0 and 3.0 µinches strikes a balance between adequate protection and minimal nickel exposure. Excessively thick gold layers increase cost and may enhance galvanic corrosion during plating.

In applications where ENIG poses persistent risks, alternative surface finishes may be considered:

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) — adds a palladium barrier to prevent nickel corrosion.

Immersion Silver (ImAg) — simpler process with good solderability, though less oxidation-resistant.

Organic Solderability Preservatives (OSP) — low-cost and environmentally friendly for short-term use.

However, ENIG remains the dominant finish for fine-pitch, lead-free, and high-reliability PCBs—provided that Black Pad prevention measures are rigorously applied.

The Black Pad phenomenon remains one of the most insidious reliability threats in modern PCB manufacturing. Its microscopic corrosion mechanisms, hidden beneath the gold surface, can silently compromise solder joints and long-term product performance.

Through decades of research, the industry has gained a deep understanding of how chemical imbalance, improper plating parameters, and poor material control can lead to Black Pad formation. Yet, the real challenge lies not only in detection but in prevention — a task that demands rigorous process control, continuous monitoring, and collaboration with reliable manufacturing partners.

The emergence of advanced finishes like ENEPIG, combined with AI-driven plating control and green chemistry innovations, represents a promising future. By adopting these technologies and adhering to strict international standards, manufacturers can significantly reduce the risk of Black Pad and ensure consistent PCB reliability.

Ultimately, success in this domain requires more than technology — it requires discipline, data-driven insight, and partnerships with experienced manufacturers like JM PCB, who bring both expertise and accountability to the production line.

The battle against Black Pad is, in essence, a pursuit of perfection in the smallest details — a reflection of the PCB industry’s ongoing commitment to excellence, reliability, and innovation.

1. How can partnering with a qualified PCB manufacturer reduce Black Pad risk?

A certified manufacturer like JM PCB employs precise process control, real-time chemical monitoring, and continuous quality verification. Such expertise minimizes the possibility of chemical imbalance, ensuring consistent plating and long-term reliability.

2. What causes nickel corrosion during ENIG plating?

Nickel corrosion typically results from imbalanced bath chemistry, high gold ion concentration, or improper pH control during immersion gold deposition. Excessive nickel dissolution leads to non-wettable areas known as Black Pad.

3. How can process engineers detect early signs of Black Pad?

Early signs include dull or discolored nickel surfaces, nodular growths under gold, and abnormal wetting during solderability tests. Advanced microscopy and EDS analysis can confirm the presence of hyper-corroded nickel.

4. Are there surface finishes that completely eliminate the risk of Black Pad?

Yes. Alternatives such as ENEPIG, Immersion Silver (IAg), and OSP finishes eliminate or significantly reduce the risk because they either block nickel exposure or avoid nickel entirely.

5. What testing methods are most effective for identifying Black Pad in production?

Cross-sectional SEM imaging, XRF analysis, and chemical etching are commonly used. These methods reveal nickel corrosion depth, gold thickness, and phosphorus distribution patterns.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote