In the rapidly evolving world of high-performance electronics, the materials used in printed circuit boards (PCBs) have become more than just a foundation — they are strategic enablers of speed, reliability, and innovation. As devices continue to shrink while performance demands soar, the limitations of traditional materials like FR-4 have become increasingly evident. Engineers and material scientists are now looking toward advanced resin systems that can withstand heat, maintain dimensional stability, and support high-frequency signal transmission.

Among these next-generation materials, BT Epoxy Resin stands out as one of the most critical and transformative options. Originally developed for semiconductor packaging, BT (Bismaleimide Triazine) resin has evolved into a core material for high-speed, high-frequency PCB applications. It offers a balance between thermal stability, dielectric performance, and mechanical strength that few other materials can match.

The story of BT Epoxy Resin is not just about chemistry — it is about how a meticulously engineered material redefines the boundary between reliability and performance. This article explores why BT Epoxy Resin has become a cornerstone of advanced PCB manufacturing, what its unique properties are, how it contributes to cost efficiency, and why leading manufacturers such as JM PCB leverage it to achieve superior board quality.

In today’s electronics landscape, every nanosecond matters, and every degree of thermal tolerance can determine product success or failure. Understanding BT Epoxy Resin is therefore not only an exercise in materials science but also a key to mastering the future of high-performance electronics.

BT Epoxy Resin

To appreciate the role of BT Epoxy Resin in modern PCBs, it is important to first understand its origin, chemical structure, and the performance attributes that make it distinct from conventional epoxy systems.

BT Epoxy Resin is a thermosetting polymer composed primarily of bismaleimide (BMI) and triazine compounds. It was developed in the late 20th century as a high-performance alternative to traditional epoxy systems, particularly for demanding semiconductor packaging and multilayer circuit applications. The combination of bismaleimide and triazine provides exceptional thermal stability, low dielectric constant (Dk), and low dissipation factor (Df) — parameters critical for high-frequency and high-speed circuit integrity.

Where standard FR-4 laminates begin to degrade around 130–150°C, BT Epoxy Resin maintains performance stability up to 200°C or higher, depending on formulation. This resilience enables PCBs to operate safely in harsh environments such as aerospace, automotive control modules, power amplifiers, and 5G communication infrastructure.

The unique molecular structure of BT Epoxy Resin contributes to its cross-linked network density, which provides both rigidity and resistance to thermal expansion. Its glass transition temperature (Tg) is significantly higher than conventional materials, ensuring dimensional stability under soldering and reflow conditions.

The performance characteristics of BT Epoxy Resin are directly tied to its chemical makeup. Unlike pure epoxy resins, which rely on bisphenol-A diglycidyl ether systems, BT resins combine maleimide and triazine structures into a unified polymer network. The result is a hybrid resin that inherits the best of both chemistries — the toughness of epoxy and the heat resistance of BMI resins.

Typical properties of BT Epoxy Resin include:

| Property | BT Epoxy Resin Typical Value | Standard FR-4 Comparison |

|---|---|---|

| Tg (Glass Transition Temperature) | 180–250°C | 130–150°C |

| Dielectric Constant (Dk) @ 1GHz | 3.2–3.8 | 4.2–4.7 |

| Dissipation Factor (Df) @ 1GHz | 0.005–0.015 | 0.02–0.03 |

| Coefficient of Thermal Expansion (CTE) (Z-axis) | 45–60 ppm/°C | 70–90 ppm/°C |

| Water Absorption | < 0.15% | 0.25–0.35% |

These data demonstrate why BT Epoxy Resin is ideal for multilayer and high-frequency PCB applications. Lower Dk and Df values translate to reduced signal loss and improved impedance control, while the lower CTE ensures alignment and dimensional accuracy across stacked layers.

In high-speed PCBs, thermal reliability is often the deciding factor between long-term functionality and premature failure. The thermal stability of BT Epoxy Resin is a major differentiator. With a decomposition temperature exceeding 350°C and excellent oxidation resistance, BT-based laminates and prepregs can handle repeated soldering and high-power operation without degradation.

Moreover, BT Epoxy Resin’s low moisture absorption prevents delamination, blistering, and dielectric breakdown — problems that often plague FR-4 materials under reflow conditions. This stability also means that BT laminates can be used in lead-free soldering processes, which operate at higher temperatures than traditional tin-lead systems.

The rigidity of BT Epoxy Resin gives it mechanical advantages that are especially important for fine-pitch BGA and CSP packaging. Its high modulus ensures that the PCB remains flat and dimensionally accurate even under complex thermal cycles.

Dimensional control is crucial for high-layer-count PCBs, where cumulative expansion errors can cause misalignment of vias or registration issues. BT resin systems exhibit extremely low warpage and maintain consistent thickness across large panel sizes.

Additionally, because BT Epoxy Resin has a well-balanced ratio between toughness and stiffness, it resists cracking under mechanical stress — a benefit for PCBs exposed to vibration or flexing, such as in automotive radar modules or portable devices.

BT Epoxy Resin is designed to integrate seamlessly into standard PCB manufacturing processes. It is compatible with glass cloth reinforcement, enabling the formation of BT-based laminates with diverse mechanical profiles. The material supports high-layer stacking, fine-line imaging, and via drilling, both mechanical and laser-based.

Manufacturers appreciate that BT resin systems can be processed on existing equipment with only minor parameter adjustments. Cure profiles, for instance, can be optimized to achieve complete cross-linking without sacrificing throughput. Furthermore, BT resins exhibit good adhesion to copper foils, which is critical for maintaining peel strength and minimizing delamination risks.

While BT Epoxy Resin is more expensive than traditional FR-4, it offers a significantly better cost-to-performance ratio when evaluated over the product lifecycle. Its superior reliability reduces field failures and rework rates, leading to lower total ownership costs.

Moreover, advances in formulation and manufacturing have made BT resin systems increasingly cost-competitive. Leading PCB manufacturers such as JM PCB have invested in optimized lamination techniques and efficient material utilization strategies to bring down per-unit production costs without compromising on quality.

While conventional FR-4 laminates have long dominated the PCB industry due to their cost efficiency and broad usability, the rapid expansion of high-speed and high-frequency applications has made performance-oriented materials such as BT Epoxy Resin indispensable. The unique physical and electrical attributes of BT Epoxy Resin not only enhance board reliability but also redefine what designers can achieve in thermal, mechanical, and signal domains.

As microprocessors, communication modules, and RF systems become faster and more compact, signal integrity and power management challenges have intensified. The dielectric characteristics of the substrate — including its dielectric constant (Dk) and dissipation factor (Df) — directly influence transmission speed and signal quality.

Traditional FR-4 materials are no longer sufficient for maintaining low signal loss at gigahertz frequencies. In contrast, BT Epoxy Resin provides a lower and more stable dielectric constant across a wide frequency range, reducing cross-talk and propagation delay. This consistency allows designers to meet strict impedance requirements, especially in differential pair routing and controlled impedance traces used in high-speed memory interfaces (DDR4, DDR5) and communication systems.

Moreover, as devices increasingly operate under thermal stress — from automotive radar to industrial automation — the high glass transition temperature (Tg) of BT Epoxy Resin ensures minimal dimensional variation. This stability keeps vias aligned and solder joints intact, preventing early degradation and functional drift over the product’s lifespan.

One of the primary benefits of BT Epoxy Resin is its superior thermal stability and low coefficient of thermal expansion (CTE). These features allow PCBs to endure multiple solder reflow cycles and continuous high-temperature operation without delamination or cracking.

In high-performance PCBs, especially those designed for power electronics, RF amplifiers, or base station transceivers, heat dissipation is a constant concern. BT Epoxy Resin mitigates this issue by offering both thermal endurance and excellent adhesion to copper, ensuring that heat generated at component junctions is effectively spread through the board structure.

Some formulations of BT Epoxy Resin are engineered with enhanced thermal conductivity additives, allowing designers to maintain optimal thermal profiles without resorting to metal-core PCBs or ceramic substrates. This makes BT-based laminates a balanced choice between performance and manufacturing cost.

In advanced multilayer designs, the low z-axis expansion of BT Epoxy Resin also ensures that through-hole and microvia integrity is maintained under temperature cycling — a critical reliability factor for high-density interconnect (HDI) boards.

The rise of 5G, satellite communications, and high-speed computing has placed greater emphasis on signal integrity (SI). For frequencies above 10 GHz, even minor material inconsistencies can result in severe insertion loss or timing errors.

The low dielectric loss tangent of BT Epoxy Resin minimizes high-frequency attenuation, preserving waveform shape and reducing phase delay. Additionally, the resin’s uniform dielectric profile across temperature and humidity variations ensures predictable propagation speed, making it easier to model and simulate transmission line behavior.

Compared to FR-4 or polyimide, BT-based materials maintain more consistent impedance values and exhibit less dielectric drift, particularly beneficial for differential pairs, stripline, and microstrip designs. These qualities make BT Epoxy Resin ideal for high-speed digital circuits, microwave modules, and antenna feed networks.

For systems operating under mixed-signal environments — combining analog, RF, and digital circuits — BT Epoxy Resin helps prevent cross-domain interference, ensuring clear signal boundaries and improved noise suppression.

The physical toughness and dimensional control of BT Epoxy Resin make it ideal for fabricating high-layer-count PCBs, which often exceed 12 or even 20 layers in server motherboards or network equipment.

During lamination, resin flow control is vital for ensuring even dielectric thickness and maintaining alignment between layers. BT Epoxy Resin’s controlled viscosity and curing behavior ensure minimal resin starvation or void formation, which contributes to superior layer bonding strength and reliability.

Its compatibility with laser-drilled microvias also supports advanced HDI stack-ups, allowing manufacturers to combine blind and buried vias with tight interlayer registration. The result is improved routing density and compact design flexibility without compromising structural stability.

Furthermore, BT Epoxy Resin demonstrates excellent copper peel strength, an essential characteristic that maintains conductor integrity even after repeated thermal or mechanical stresses. This property makes it suitable for rigid-flex hybrid constructions where both rigidity and flexibility must coexist.

In high-frequency design, every material characteristic — dielectric constant, moisture absorption, and smoothness of copper interface — affects signal performance. BT Epoxy Resin excels in all these aspects.

Its low water absorption (<0.15%) ensures stable dielectric properties in humid environments, reducing signal reflection and impedance fluctuation. Meanwhile, its surface compatibility with rolled or treated copper foils enhances adhesion and minimizes conductor surface roughness, leading to better high-frequency performance.

For applications such as millimeter-wave radar, satellite communication modules, or 5G antennas, BT Epoxy Resin-based laminates deliver consistent performance across the frequency band. The reduced dielectric loss enables longer transmission lines with minimal attenuation, which simplifies circuit design and extends operational range.

Designers often combine BT Epoxy Resin with low-loss reinforcement glass or ceramic fillers to further fine-tune the dielectric profile. These hybrid formulations offer custom solutions for applications requiring precision-controlled impedance and low phase noise — such as phased array radar systems or RF front-end modules.

Beyond conventional PCB use, BT Epoxy Resin is widely utilized in IC substrates and semiconductor packaging due to its outstanding dimensional stability and electrical insulation. Bismaleimide-triazine compounds form a rigid polymer matrix that minimizes warpage and maintains flatness, even as the substrate undergoes thermal expansion during chip mounting.

These characteristics make BT resin systems ideal for ball grid array (BGA), chip-scale package (CSP), and flip-chip interposers. BT-based substrates also exhibit excellent chemical resistance, ensuring durability during electroplating, etching, and cleaning processes.

Manufacturers favor BT Epoxy Resin for packaging because it strikes an ideal balance between mechanical robustness and fine-line capability, allowing for tighter design tolerances and improved interconnection density.

The superior characteristics of BT Epoxy Resin naturally place it above standard laminates in price, but it delivers substantial value in long-term reliability, lower defect rates, and higher yield.

Leading manufacturers, such as JM PCB, have developed proprietary process optimizations that maximize yield from each BT resin panel. These include precision lamination pressure control, adaptive curing profiles, and scrap reduction through automated optical inspection alignment systems.

Through these advancements, JM PCB offers clients cost-effective BT-based solutions that rival traditional FR-4 options in competitiveness while outperforming them in durability and performance.

The overall lifecycle cost of a BT Epoxy Resin-based PCB often turns out lower due to fewer replacements, minimized downtime, and better end-user reliability. In sectors like defense, aerospace, and medical instrumentation, where repair or failure costs can be catastrophic, BT resin systems are a logical and economical choice despite their higher upfront price.

As environmental standards tighten globally, material sustainability is becoming an important factor in PCB selection. Many modern formulations of BT Epoxy Resin are halogen-free and RoHS-compliant, aligning with international environmental regulations without sacrificing performance.

Material scientists are also experimenting with bio-based triazine monomers and enhanced curing agents to lower energy consumption during lamination. Furthermore, BT Epoxy Resin’s longer operational lifespan indirectly contributes to sustainability by reducing waste and extending product cycles.

Future trends suggest increasing adoption of BT hybrid materials — combining BT resin with polyimide or PTFE fillers — to push performance limits for next-generation 6G, AI, and quantum computing hardware. The versatility and adaptability of BT chemistry ensure it will remain central to advanced electronics for decades to come.

The global PCB industry has long relied on established materials like FR-4 and polyimide. Yet, as the boundaries of performance continue to expand, BT Epoxy Resin has demonstrated its superiority in critical domains where traditional substrates fall short. Understanding its advantages helps engineers justify material selection not only on a performance basis but also from a strategic and cost-efficiency perspective.

For decades, FR-4 has been the workhorse of the PCB industry — affordable, versatile, and easy to process. However, its limitations have become evident as electronic systems demand higher speed, greater power density, and more compact geometries.

In contrast, BT Epoxy Resin introduces a new level of material sophistication. Its lower dielectric constant (Dk) and lower dissipation factor (Df) dramatically reduce signal loss, making it ideal for circuits operating above 1 GHz. While FR-4 materials often struggle with dielectric instability beyond these frequencies, BT maintains stable electrical properties up to 10 GHz and beyond.

Thermally, FR-4 begins to deform or lose dimensional control at temperatures above 150 °C, while BT Epoxy Resin maintains structure integrity above 200 °C. This allows it to support lead-free reflow processes, which reach peak temperatures around 260 °C — a requirement in environmentally compliant manufacturing.

Mechanically, BT’s tighter molecular cross-linking yields better rigidity and lower z-axis expansion, ensuring that vias and plated through-holes remain intact even after multiple heating cycles. This alone can significantly enhance PCB reliability in mission-critical applications.

Polyimide has long been known for its extreme thermal endurance, often exceeding 300 °C. However, it comes with trade-offs: higher moisture absorption, greater dielectric loss, and higher processing cost.

BT Epoxy Resin offers a more balanced solution. While slightly lower in maximum temperature capability than pure polyimide, BT resins achieve comparable thermal stability with better dielectric performance and lower hygroscopicity. Its lower water uptake (< 0.15 %) maintains consistent dielectric properties, preventing performance drift in humid environments — a common problem in polyimide-based PCBs.

Furthermore, polyimide’s complex curing and handling requirements make it more expensive to process, while BT Epoxy Resin remains compatible with standard FR-4 manufacturing equipment. This compatibility minimizes capital investment and simplifies production transitions for PCB fabricators.

The result is a practical compromise: BT materials deliver 90 % of polyimide’s heat tolerance with improved electrical efficiency and substantially lower cost. For high-frequency digital and RF circuits, this trade-off is highly attractive.

As transmission rates exceed 25 Gbps and digital rise times drop below 100 ps, substrate dielectric performance becomes paramount. BT Epoxy Resin outperforms standard epoxy systems by maintaining consistent impedance and low insertion loss across a broad frequency spectrum.

Its dielectric constant remains stable even as frequency rises — typically between 3.2 and 3.6 — while FR-4 can fluctuate by 10 % or more in the same range. This stability ensures that trace impedance remains within design tolerance, preventing reflections that could distort high-speed signals.

Additionally, the smooth copper interface achievable with BT resin laminates further reduces conductor loss. At high frequencies, surface roughness on copper traces contributes significantly to attenuation; BT resin’s excellent adhesion allows the use of rolled-annealed or treated copper foils with minimal roughness.

In combination, these properties give BT-based PCBs a measurable edge in applications such as high-speed routers, data-center interconnects, and aerospace control systems.

Electronic systems today are often exposed to environments far outside laboratory conditions: automotive under-hood areas, aerospace avionics, and renewable-energy converters all demand exceptional material resilience.

BT Epoxy Resin is designed for precisely such conditions. Its low coefficient of thermal expansion (CTE) minimizes mechanical stress between copper and dielectric layers, reducing the risk of cracking or delamination. The resin’s inherent oxidation resistance protects against thermal degradation even under continuous high-temperature exposure.

Moisture and chemical resistance also play vital roles. The triazine component of BT resin forms a highly cross-linked polymer network that resists hydrolysis and acid attack. This gives BT-based PCBs an extended service life in corrosive or humid environments — conditions where FR-4 typically exhibits dielectric swelling or loss of adhesion.

In practical terms, this means fewer field failures, longer maintenance intervals, and improved reliability metrics, particularly in safety-critical sectors.

As PCB feature sizes shrink, dimensional stability becomes a decisive parameter in manufacturing yield. BT Epoxy Resin exhibits superior coefficient-of-thermal-expansion uniformity, resulting in reduced layer misalignment and precise registration in multilayer lamination.

When fabricating boards with 12 or more layers, even a few microns of misalignment can render the entire panel unusable. BT resin’s predictable behavior under pressure and heat ensures that stacked layers remain perfectly aligned.

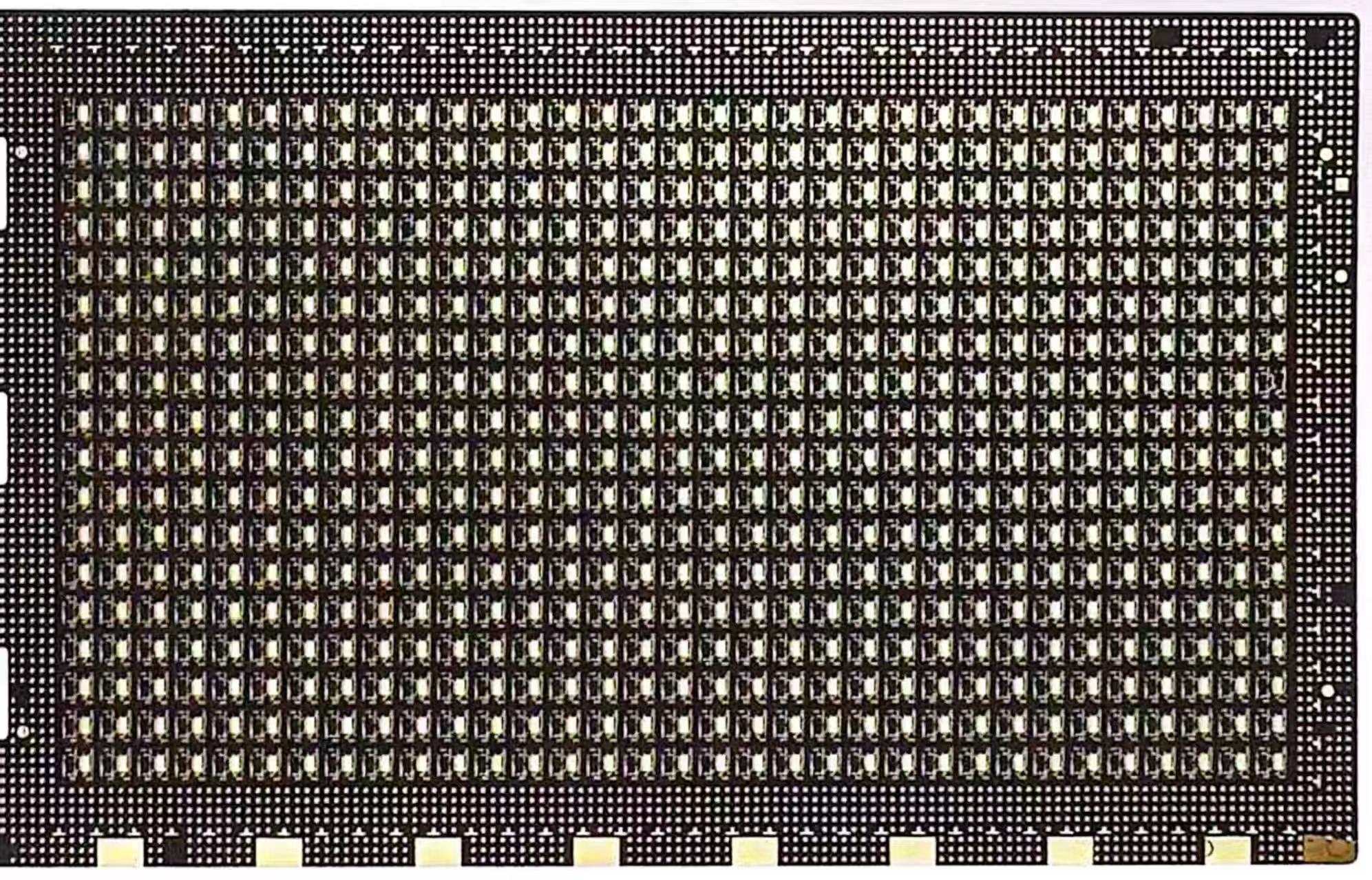

Manufacturers like JM PCB exploit this property to produce fine-line multilayer boards with sub-75 µm trace widths and microvias, which are increasingly common in 5G modules and miniaturized sensor circuits. Their optimized lamination controls and thermal modeling systems take full advantage of BT resin’s stability, yielding consistent, high-density interconnects with minimal rework.

The long-term performance of a PCB is often judged by its ability to resist delamination, maintain electrical insulation, and prevent via fatigue after thousands of thermal cycles. BT Epoxy Resin excels in all these criteria.

Because of its high glass transition temperature and robust molecular network, it resists mechanical fatigue far better than standard epoxy materials. Vias plated in BT-based substrates demonstrate lower resistance variation over time, a clear indicator of mechanical integrity.

Thermal cycling tests consistently show that BT resin systems sustain over 1,000 cycles between –40 °C and 125 °C without noticeable structural degradation — a key requirement in automotive reliability standards such as AEC-Q200.

Additionally, BT resin’s low ionic contamination and superior insulation resistance protect against electrochemical migration, a common cause of field failures in humid conditions.

It is natural to associate advanced materials with higher costs, but BT Epoxy Resin demonstrates that innovation can coexist with efficiency. Its stable processing window allows manufacturers to maintain high yields even at fine geometries, reducing scrap and rework.

Modern resin formulations require fewer lamination cycles and shorter cure times than early BT systems, contributing to productivity gains. Equipment wear is also reduced because of the resin’s clean drilling characteristics and controlled resin flow.

Leading companies like JM PCB have implemented lean manufacturing principles around BT resin processing, integrating automated layer alignment and in-situ curing analytics. These innovations streamline throughput while ensuring every panel meets the rigorous standards demanded by aerospace and telecom clients.

When lifecycle economics are considered — including reduced field returns, extended service life, and higher customer satisfaction — BT Epoxy Resin consistently proves to be the smarter financial choice.

The evolution toward HDI design has placed enormous pressure on material dimensional control and via reliability. BT Epoxy Resin’s combination of rigidity and low CTE makes it exceptionally well-suited to microvia reliability.

In stacked via structures, where laser-drilled holes are filled and plated, z-axis expansion mismatches can easily cause cracking. BT resin minimizes this risk, maintaining electrical continuity even after numerous reflow cycles.

Moreover, the resin’s compatibility with sequential lamination enables complex build-up processes that are increasingly standard in modern smartphone, radar, and computing platforms. Its predictable dielectric behavior simplifies impedance modeling, shortening design iterations and improving first-pass success rates.

Engineers often approach new materials cautiously, but BT Epoxy Resin has earned broad acceptance for its balance of performance, manufacturability, and reliability. It fills a critical gap between cost-sensitive FR-4 and ultra-high-end PTFE composites.

Key reasons for its adoption include:

Thermal stability suited to lead-free assembly.

Electrical consistency ideal for high-frequency designs.

Mechanical rigidity for multilayer accuracy.

Low moisture absorption for environmental robustness.

Process compatibility with conventional FR-4 infrastructure.

These combined advantages make BT resin a practical stepping stone toward the next generation of materials without disrupting established production ecosystems.

While BT Epoxy Resin is widely recognized for its superior electrical, thermal, and mechanical performance, another equally significant aspect deserves attention — its economic efficiency. For many PCB manufacturers and design engineers, cost is a determining factor in material selection. Although BT resin materials are priced higher per square meter than conventional FR-4, their total lifecycle cost is often much lower when measured in terms of reliability, yield, and end-use durability.

This section explores how BT Epoxy Resin enables cost-effective manufacturing, how it supports lean production principles, and how companies such as JM PCB utilize advanced process control to maintain competitiveness in high-value markets.

At first glance, BT Epoxy Resin appears costlier than FR-4 — sometimes by 30% to 50%. However, this raw material cost difference can be misleading when evaluated without considering yield, reliability, and field performance.

In high-reliability industries, such as aerospace, telecommunications, or automotive electronics, the cost of product failure is often magnitudes higher than the marginal cost of premium materials. Field replacements, downtime, warranty claims, and safety issues can accumulate expenses that dwarf material savings.

BT Epoxy Resin’s superior reliability directly translates into lower defect rates and longer operational lifespans, which in turn reduce total cost of ownership (TCO). When the full cost model is analyzed — from raw material procurement through product life — BT resin systems typically deliver a 10–20% net cost advantage over time.

A crucial component of cost control in PCB production is material utilization. BT Epoxy Resin, due to its excellent lamination uniformity and predictable resin flow, minimizes waste during lay-up and pressing.

In traditional FR-4 systems, resin starvation or uneven flow can lead to voids, delamination, or uneven dielectric thickness, all of which increase rework and scrap rates. BT’s controlled viscosity behavior ensures consistent dielectric thickness across panels, even at high layer counts.

This uniformity improves manufacturing yield and reduces the number of defective boards per production run. Studies conducted in high-volume fabrication facilities have demonstrated yield improvements of 5–8% when switching from standard FR-4 to BT resin laminates — a significant gain that offsets the material premium.

Time efficiency is an often-overlooked cost factor. Traditional high-performance materials like polyimide require long curing cycles and careful moisture conditioning. BT Epoxy Resin, however, offers a balanced cure profile that fits well into existing lamination workflows.

Curing times can be optimized to as little as 60–90 minutes, allowing manufacturers to complete more lamination cycles per day. Additionally, BT resin’s stable flow characteristics simplify layer alignment and reduce the number of failed stack-ups.

Modern BT resin systems are engineered for low-void, high-speed lamination, which significantly cuts down on process time. Manufacturers report that BT-based multilayer boards can be processed with up to 20% shorter cycle times compared to equivalent polyimide systems.

Switching to a new base material often requires retooling or new capital investment — a major deterrent for many PCB fabricators. However, BT Epoxy Resin was formulated to ensure compatibility with standard FR-4 manufacturing lines.

Existing pressing, drilling, imaging, and etching equipment can handle BT resin laminates with minimal parameter adjustments. For instance, mechanical drilling parameters only require slightly reduced spindle speeds to prevent resin cracking. Likewise, desmear and plasma processes remain within standard ranges.

This seamless compatibility means manufacturers can upgrade performance without costly infrastructure overhauls. For smaller and mid-sized PCB producers, this represents a critical strategic advantage — an opportunity to enter high-value markets like 5G infrastructure or aerospace electronics without large upfront investment.

In PCB production, scrap rates often originate from warpage, delamination, and registration misalignment — all symptoms of material instability. Because BT Epoxy Resin offers superior dimensional control, it drastically reduces these forms of waste.

During multilayer lamination, the resin’s low CTE and high Tg minimize warping, ensuring that copper features align perfectly between layers. This mechanical precision leads to higher yields in fine-line circuits and HDI structures.

Rework is another hidden cost that erodes profitability. A board requiring multiple touch-ups or repairs not only consumes more labor but can also compromise long-term reliability. BT Epoxy Resin’s resistance to moisture absorption and oxidation allows boards to survive multiple soldering cycles without blistering or delamination, dramatically reducing rework frequency.

For large-scale manufacturers, even a 1% decrease in scrap rate translates into thousands of dollars in savings per batch.

One of the industry leaders in integrating BT resin systems efficiently is JM PCB, a company known for its precision multilayer and high-frequency PCB manufacturing. JM PCB has established dedicated production lines optimized for BT-based laminates, allowing the company to maintain competitive pricing without sacrificing quality.

By utilizing real-time process monitoring, statistical process control (SPC), and AI-assisted yield optimization, JM PCB maximizes material usage efficiency while minimizing energy consumption. Their lamination pressure and temperature profiles are customized for each BT resin formulation, reducing over-curing and improving interlayer adhesion.

In addition, JM PCB has developed partnerships with major material suppliers to secure consistent quality and bulk pricing, which directly benefits customers. By leveraging these economies of scale, the company delivers high-reliability BT resin boards at price points that rival standard FR-4 products in total lifecycle cost.

Their expertise illustrates that performance and affordability are not mutually exclusive — rather, they can coexist when guided by engineering precision and data-driven manufacturing.

One of the biggest economic benefits of BT Epoxy Resin is its contribution to reliability-driven cost savings. A board that performs consistently for 10 years in the field is vastly more valuable than one that requires replacement after 3.

Failures caused by substrate degradation, via cracking, or dielectric instability often result in expensive recalls or warranty claims. BT Epoxy Resin’s robust physical and chemical stability virtually eliminates these risks, making it the preferred choice for automotive ADAS systems, aerospace avionics, and military-grade electronics.

These industries operate on the principle of cost avoidance through reliability — a philosophy perfectly aligned with BT material characteristics.

Moreover, BT resin’s thermal endurance ensures lead-free compatibility and fewer process defects during assembly. This translates directly to lower return rates and customer complaints, further improving the manufacturer’s financial efficiency.

Environmental compliance is no longer a luxury — it’s a necessity. BT Epoxy Resin is available in halogen-free and RoHS-compliant formulations, which allow manufacturers to meet international green manufacturing standards without additional processing steps.

In addition to regulatory benefits, these eco-friendly resins reduce the cost associated with waste treatment and emissions control. Many traditional epoxy systems release volatile organic compounds (VOCs) during curing; modern BT formulations minimize such emissions through cleaner chemical cross-linking.

Furthermore, the longer product life of BT-based boards indirectly contributes to sustainability by reducing e-waste. A PCB that lasts longer reduces material consumption across the supply chain, thereby lowering environmental and disposal costs.

The total cost of ownership model provides a holistic view of material economics by considering acquisition, production, operation, maintenance, and end-of-life phases. When analyzed under this framework, BT Epoxy Resin consistently outperforms traditional materials.

| Cost Factor | FR-4 | Polyimide | BT Epoxy Resin |

|---|---|---|---|

| Raw Material Cost | Low | High | Moderate |

| Manufacturing Yield | Moderate | Moderate | High |

| Thermal Durability | Limited | Excellent | Excellent |

| Dielectric Stability | Limited | Moderate | High |

| Environmental Compliance | Partial | Moderate | High |

| Lifecycle Reliability | Medium | High | Very High |

| Total Cost of Ownership (TCO) | Moderate | High | Lowest |

These results demonstrate that BT Epoxy Resin delivers a lower total lifecycle cost than both FR-4 and polyimide — an outcome driven by its balance of performance, reliability, and manufacturability.

Selecting BT Epoxy Resin is not merely a technical decision — it is a strategic investment. It represents a commitment to quality, reliability, and long-term brand reputation. In markets where performance defines success — such as aerospace, telecommunications, or high-speed computing — material choice often becomes the distinguishing factor between technological leadership and obsolescence.

By adopting BT Epoxy Resin, manufacturers demonstrate to customers and partners that they prioritize engineering excellence over short-term savings. The return on this investment is measured in customer loyalty, product reliability, and competitive advantage.

In high-performance PCB manufacturing, material compatibility with process steps is often the hidden variable that defines success. BT Epoxy Resin, with its balanced curing kinetics and controlled rheology, has proven remarkably adaptable to mainstream PCB fabrication workflows.

The resin’s viscosity profile allows uniform impregnation into fiberglass substrates, reducing the risk of voids and ensuring homogeneous lamination. During the lamination stage, BT Epoxy Resin maintains dimensional control, preventing resin recession and ensuring even dielectric thickness — a crucial factor in impedance-controlled PCBs.

Furthermore, the resin’s stable flow behavior means it does not excessively bleed during press cycles, preserving copper pattern fidelity. This makes it an ideal candidate for high-density interconnect (HDI) stack-ups, where interlayer registration accuracy is paramount.

Manufacturers leveraging BT-based laminates report higher yields due to fewer delamination and void-related defects. When properly cured, BT Epoxy Resin forms a chemically stable crosslinked matrix that withstands subsequent desmear, plating, and etching processes without deformation or adhesion loss.

Lamination optimization is one of the most critical aspects of working with BT Epoxy Resin. Its curing temperature window typically lies between 180°C and 220°C, depending on formulation and reinforcement type. Engineers must design lamination cycles that ensure complete polymer crosslinking without inducing resin stress.

A well-controlled multi-stage temperature ramp is recommended — starting at moderate temperatures for resin flow and venting, followed by a high-temperature hold to finalize curing. This ensures that BT Epoxy Resin reaches its full mechanical and thermal potential, maximizing Tg and minimizing internal stress.

In multilayer PCB manufacturing, BT-based prepregs require precise pressure control during pressing. Overpressure can cause excessive resin squeeze-out, whereas insufficient pressure risks poor layer adhesion. Manufacturers like JM PCB have fine-tuned their lamination parameters using real-time feedback and vacuum lamination technology to ensure optimal resin distribution and void-free stacking — a key contributor to their consistent product reliability.

One of the challenges with high-Tg materials is drillability — the ability to form clean, burr-free holes without resin cracking or smear. BT Epoxy Resin’s unique toughness helps balance this trade-off. It provides excellent mechanical integrity while maintaining sufficient elasticity to absorb drilling stress.

For mechanical drilling, optimized bit geometries and entry/exit materials are used to prevent resin chipping. BT resin’s low glass fiber pullout tendency ensures clean via walls, facilitating uniform electroless copper deposition in subsequent steps.

Laser drilling is also highly compatible with BT Epoxy Resin. The resin’s controlled ablation rate minimizes carbonization and ensures smooth via profiles. This is especially important for microvias in HDI multilayer PCBs, where consistent dielectric thickness and clean via quality directly affect signal transmission.

JM PCB, for example, employs laser-based via optimization algorithms that account for BT resin’s absorption characteristics. This allows precise control over laser parameters, minimizing via wall damage while maintaining high production throughput.

Assembly is where the true performance of BT Epoxy Resin becomes evident. Lead-free soldering processes often exceed 245°C, which challenges standard FR-4 boards. BT-based PCBs, however, retain mechanical strength and dielectric stability even under multiple reflow cycles.

The high Tg and low CTE of BT Epoxy Resin mitigate the risk of barrel cracking, pad lifting, and delamination during soldering. This ensures strong interfacial adhesion between copper pads and dielectric layers.

Additionally, BT Epoxy Resin’s low moisture absorption reduces the chance of “popcorning” or blister formation during thermal shock. These properties are vital for boards used in aerospace or automotive electronics, where repeated thermal cycling is routine.

High-speed communication boards also benefit from BT resin’s low dielectric loss, which helps maintain impedance control even after multiple thermal exposures. Long-term reliability tests — such as temperature-humidity-bias (THB) and pressure cooker tests (PCT) — consistently show that BT-based laminates outperform traditional epoxy systems under accelerated aging conditions.

As sustainability becomes a key driver in electronics production, BT Epoxy Resin presents unique opportunities for eco-conscious manufacturing. Although the base resin system is synthetic, its high performance per material volume means fewer layers and lower energy requirements per function achieved.

Modern formulations of BT resin are increasingly being optimized for low VOC emissions, reduced waste, and enhanced recyclability of scrap materials. Manufacturers are experimenting with bio-derived epoxy modifiers to partially replace petroleum-based components without sacrificing performance.

Moreover, the longer operational lifetime of BT-based PCBs contributes indirectly to sustainability — products last longer, require fewer replacements, and generate less electronic waste.

JM PCB has taken notable steps in this direction by implementing closed-loop lamination systems and energy-efficient curing ovens that minimize carbon emissions. This not only enhances process sustainability but also aligns with international standards such as ISO 14001 for environmental management.

Copper adhesion strength is essential for long-term circuit reliability. The molecular structure of BT Epoxy Resin naturally promotes good adhesion due to polar triazine groups that bond effectively with copper oxides.

To further enhance adhesion, manufacturers may apply oxide replacement or bonding treatments, ensuring robust copper-to-resin interfacial strength. BT resins demonstrate high peel strength even after thermal aging, making them ideal for fine-line circuits that must resist delamination during soldering or rework.

In high-frequency PCBs, where surface smoothness is critical for signal performance, BT-based laminates allow the use of rolled or reverse-treated copper foils that minimize conductor roughness. This not only improves impedance control but also contributes to reduced insertion loss at gigahertz frequencies.

Although BT Epoxy Resin has a higher raw material cost, total production costs can be managed — and even reduced — through process optimization. Manufacturers can take advantage of its dimensional stability and low defect rate to minimize scrap and rework.

Advanced curing control also allows shorter press cycles, improving throughput. Combined with reduced material waste, the operational efficiency achieved offsets initial resin expenses.

JM PCB, for instance, integrates statistical process control (SPC) and AI-driven predictive maintenance into their BT resin lamination lines. By monitoring resin flow dynamics and curing profiles, they achieve nearly 99.8% yield consistency across production batches — demonstrating how material intelligence and process integration lead to economic advantages.

The demand for higher speed, miniaturization, and energy efficiency in electronic devices is accelerating the evolution of BT Epoxy Resin formulations. Future research and industrial development are focused on enhancing dielectric properties, thermal management, and environmental compliance.

Material scientists are engineering nanocomposite BT systems, incorporating ceramic or silica nanoparticles to further reduce the dielectric constant (Dk) while maintaining low dissipation factor (Df). These nanofillers also reinforce mechanical strength and improve thermal conductivity — essential attributes for high-power or RF applications.

Another key development direction is hybrid polymer networks that combine BT resin with polyimide or cyanate ester systems. These hybrids achieve an optimized balance between processability and high-frequency performance, addressing the gap between cost and ultra-high-end materials like PTFE-based laminates.

Furthermore, low-flow BT prepregs are gaining traction for rigid-flex PCB assemblies, offering improved bonding performance without resin overflow during lamination. This is especially useful in 3D module integration, flexible interconnects, and advanced semiconductor packaging where precision and cleanliness are critical.

As sustainability pressures grow, future BT resin chemistry will emphasize halogen-free formulations, lower cure energy requirements, and enhanced recyclability — aligning with global environmental directives such as RoHS and REACH.

The versatility of BT Epoxy Resin makes it highly compatible with emerging technologies such as 5G infrastructure, autonomous vehicle electronics, wearable devices, and AI-driven computing hardware.

In 5G communication systems, BT resin’s low dielectric loss is vital for maintaining signal integrity across multilayer RF boards. The material supports frequency bands above 30 GHz, ensuring minimal transmission delay and high data throughput.

In automotive radar and ADAS systems, BT resin provides the thermal and mechanical endurance required to survive rapid temperature cycling and vibration. Its predictable dielectric behavior also ensures consistent antenna performance — a non-negotiable requirement for safety-critical systems.

Meanwhile, in semiconductor packaging and substrate-like PCBs (SLPs), BT Epoxy Resin is integral to achieving miniaturization and precision. The resin’s fine glass cloth compatibility and laser-drillable properties allow for ultra-microvias and sub-50μm trace widths, meeting the needs of advanced chips used in smartphones, AI processors, and high-speed computing devices.

JM PCB, as one of the industry’s forward-looking manufacturers, is actively implementing BT-based laminates in its high-density multilayer PCB and RF module production lines. By combining BT resin substrates with high-purity rolled copper foils and precision-controlled lamination cycles, JM PCB achieves exceptional dielectric consistency and reliability across complex circuit architectures.

Signal integrity (SI) is one of the defining performance metrics for modern PCB systems. BT Epoxy Resin, with its low dielectric constant and dissipation factor, ensures that high-speed signals experience minimal phase delay and insertion loss even at gigahertz frequencies.

The consistency of its dielectric parameters across temperature and humidity changes is equally important. Unlike conventional FR-4 materials, BT resins exhibit negligible Dk drift with temperature rise — ensuring stable impedance and predictable propagation delay.

This property becomes increasingly critical as engineers push signal speeds beyond 25–50 Gbps in advanced data transmission systems. Poor dielectric uniformity or thermal drift can lead to skew, jitter, and timing errors, all of which degrade performance.

Furthermore, the resin’s low moisture absorption minimizes signal distortion caused by water-induced dielectric variation. This makes BT resin-based laminates indispensable in aerospace communication, satellite electronics, and defense radar systems, where stable high-frequency operation is required in extreme conditions.

As electronic components continue to generate higher power densities, BT Epoxy Resin plays an essential role in managing heat and maintaining thermal reliability.

Its high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE) prevent mechanical stress and copper trace fatigue under repeated heating cycles. This makes BT resin particularly suitable for power amplifiers, DC-DC converters, and automotive ECUs, where thermal endurance directly affects lifespan.

To enhance thermal conductivity, advanced formulations of BT resin incorporate ceramic or boron nitride fillers. These composites provide efficient heat spreading without compromising electrical insulation.

In high-voltage PCBs, the excellent dielectric strength of BT resin ensures safety and prevents breakdowns, even under elevated thermal loads. The combination of electrical and thermal resilience contributes to longer product life cycles — a key factor in cost efficiency for both manufacturers and end-users.

Beyond performance, BT Epoxy Resin offers long-term strategic benefits for PCB manufacturers and OEMs. Its stable processing characteristics reduce yield loss, while its high mechanical integrity minimizes rework and warranty claims.

For companies like JM PCB, these advantages translate into higher operational efficiency and consistent product quality. By optimizing BT resin material flow, curing parameters, and layer registration, JM PCB has positioned itself as a leader in high-frequency PCB production, serving telecommunications, aerospace, and advanced industrial markets.

The adoption of BT resin also provides design flexibility — engineers can use thinner dielectric layers, tighter trace spacing, and higher via density without sacrificing reliability. These design freedoms enable innovation and miniaturization, giving manufacturers a competitive edge in rapidly evolving markets.

Market analysts forecast that the global demand for BT Epoxy Resin-based PCB laminates will continue to expand steadily over the next decade, driven by the proliferation of 5G, IoT, and electric vehicle (EV) technologies.

The Asia-Pacific region — particularly China, South Korea, and Taiwan — will remain the epicenter of BT resin production and PCB fabrication. However, growing interest in North American and European advanced manufacturing ecosystems is fueling the establishment of new BT resin-based substrate facilities to meet regional demand and supply chain resilience goals.

In terms of competitive dynamics, manufacturers that invest in smart process control, materials R&D, and vertical integration (such as in-house laminate and copper foil production) will have the upper hand. As performance requirements climb, customers will prioritize suppliers that can offer repeatable electrical performance, eco-friendly materials, and tight tolerance control — all areas where BT resin technology excels.

Looking ahead, BT Epoxy Resin is poised to remain a critical enabler of high-reliability PCB technology, bridging the gap between conventional epoxy and ultra-premium high-frequency materials. Its cost-effective performance balance ensures it will continue to dominate applications that require a synergy of mechanical strength, dielectric precision, and manufacturability.

The evolution of BT Epoxy Resin has transformed it from a niche semiconductor packaging material into a backbone of high-performance PCB design. Its unique combination of thermal stability, dielectric precision, mechanical strength, and manufacturability allows it to meet the increasing demands of next-generation electronics.

By offering high Tg, low CTE, and excellent signal integrity performance, BT Epoxy Resin empowers engineers to design smaller, faster, and more reliable electronic systems without prohibitive costs.

As this article has explored, leading manufacturers such as JM PCB demonstrate how mastering BT resin materials can lead to sustainable process efficiency and technological leadership. With continued advancements in resin chemistry, hybrid formulations, and nanocomposite integration, BT Epoxy Resin will continue to play a defining role in shaping the future of electronics manufacturing.

BT resin-based PCBs excel in applications demanding high thermal and electrical performance, including 5G infrastructure, radar systems, aerospace avionics, power management, and high-speed computing hardware. Their low-loss and high-reliability properties make them indispensable for cutting-edge designs.

BT Epoxy Resin has a lower dielectric constant (Dk) and dissipation factor (Df), which reduces signal loss at high frequencies. It also offers higher Tg and lower CTE, ensuring dimensional stability under thermal stress — essential for fine-pitch and multilayer circuit boards.

Yes, BT Epoxy Resin can be formulated into low-flow prepregs that allow controlled bonding without excess resin flow, making it suitable for rigid-flex assemblies. Its dimensional stability and excellent adhesion enhance interconnect reliability between flexible and rigid sections.

Although BT resin materials are more expensive than FR-4, they reduce long-term costs through higher yields, fewer failures, and extended product lifetimes. Manufacturers like JM PCB optimize BT processing to achieve cost efficiency through advanced curing control, precise lamination, and reduced scrap rates.

Modern BT resin formulations are transitioning toward halogen-free and low-VOC chemistries. Additionally, their long lifespan and superior reliability contribute to sustainability by reducing electronic waste and minimizing replacement frequency.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote