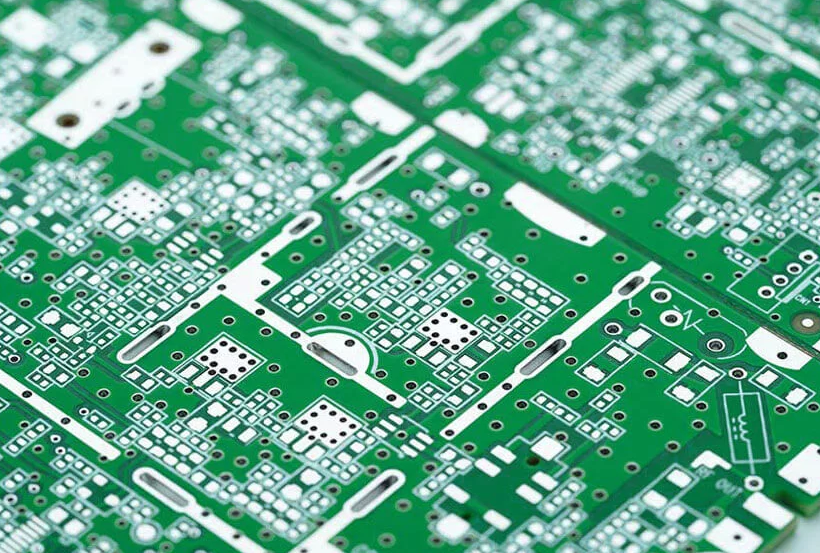

In the rapidly evolving world of printed circuit board (PCB) manufacturing, the choice of surface finish plays a crucial role in determining the board’s performance, reliability, and cost. Among the most widely used finishes, Hot Air Solder Leveling (HASL) remains a popular choice. HASL can be applied in both lead-based and lead-free formats, each offering distinct advantages and limitations.

HASL Lead vs. Lead-Free represents a critical decision point for PCB designers and manufacturers. Traditional leaded HASL uses an alloy of tin and lead to coat copper pads, offering excellent wetting properties and reliable solder joints. Lead-free HASL, on the other hand, replaces lead with alternative alloys, typically a mix of tin, silver, and copper (SAC), aligning with environmental regulations such as RoHS (Restriction of Hazardous Substances).

Understanding the nuances of HASL Lead vs. Lead-Free is essential for achieving optimal solderability, long-term durability, and cost efficiency. For manufacturers like JM PCB, offering both options ensures flexibility for clients who prioritize performance, compliance, or budget.

In this article, we will explore the technical aspects of HASL Lead vs. Lead-Free, compare their properties, examine the application processes, and provide practical insights for selecting the most suitable option for your PCB projects.

HASL Lead vs. Lead-Free

The choice between HASL Lead vs. Lead-Free is fundamentally rooted in the metallurgical properties of the solder alloys and their interaction with copper pads. Understanding the science behind these finishes is crucial for PCB designers aiming to optimize both performance and reliability.

1. Composition and Metallurgy

Leaded HASL traditionally employs a tin-lead alloy, often in the ratio of 63% tin and 37% lead (Sn63Pb37). This eutectic composition melts at a relatively low temperature of 183°C, providing smooth wetting characteristics and excellent solderability. In contrast, lead-free HASL typically uses a SAC alloy, such as SnAgCu, which melts at a higher temperature of around 217–220°C. While lead-free alloys comply with environmental regulations, they require careful temperature control during soldering to avoid thermal stress on components.

2. Surface Interaction

The interaction between the solder and copper pads differs between leaded and lead-free finishes. Leaded HASL forms a thin intermetallic layer that promotes robust solder joints, while lead-free HASL tends to create a slightly thicker intermetallic layer, which can affect mechanical strength over repeated thermal cycles. This distinction is especially important in high-reliability applications such as aerospace, medical devices, and automotive electronics.

3. Thermal and Electrical Considerations

Leaded HASL’s lower melting point reduces thermal stress on sensitive components during soldering. Lead-free HASL, due to its higher melting point, can increase the risk of thermal damage if not properly managed. Electrically, both finishes provide excellent conductivity; however, minor differences in intermetallic formation can impact long-term performance under high-frequency or high-current conditions.

4. Environmental Implications

Lead-free HASL offers significant environmental advantages, aligning with RoHS and WEEE directives, which restrict the use of hazardous substances. While leaded HASL delivers superior soldering characteristics, its use is increasingly limited due to regulatory and health considerations. Manufacturers like JM PCB provide both leaded and lead-free options to meet client requirements without compromising on quality or compliance.

By understanding the underlying science of HASL Lead vs. Lead-Free, designers can make informed decisions regarding soldering processes, thermal management, and long-term reliability. The next section will delve deeper into solderability differences, a critical factor in assembly efficiency and joint quality.

Solderability is one of the most critical factors in PCB manufacturing, directly affecting assembly efficiency, joint reliability, and long-term performance. The differences between HASL Lead vs. Lead-Free are particularly pronounced in this aspect.

1. Wetting Performance

Leaded HASL provides superior wetting characteristics due to the low melting point and eutectic composition of Sn63Pb37. This ensures that solder flows quickly and evenly over copper pads, forming smooth, defect-free joints. In contrast, lead-free HASL, often based on SAC alloys, has a higher melting point and slightly slower wetting action. This can result in uneven solder coverage or cold joints if assembly parameters are not carefully optimized.

2. Flux Compatibility

Both leaded and lead-free HASL rely on flux to remove oxides from the copper surface during soldering. Leaded HASL generally allows for more forgiving flux chemistry due to its lower temperature requirements, whereas lead-free HASL requires flux formulations that can withstand higher temperatures without decomposing or leaving residues that compromise joint reliability.

3. Reflow Considerations

Lead-free HASL requires higher reflow temperatures, typically 245–260°C, compared to 215–235°C for leaded HASL. These higher temperatures can introduce thermal stress on sensitive components and may necessitate adjustments to reflow profiles, including slower ramp rates and extended soak times, to ensure proper solder wetting without damaging the PCB.

4. Mechanical Robustness

Leaded HASL forms thin, uniform intermetallic layers that create strong, mechanically reliable solder joints. Lead-free HASL, due to a thicker intermetallic layer, may exhibit slightly increased brittleness under repeated thermal cycling. However, with proper process control, lead-free joints can achieve comparable durability for most commercial and industrial applications.

Understanding these solderability differences allows PCB designers and assemblers to minimize defects, reduce rework, and optimize production yields.

Durability is a critical factor in determining the long-term performance of printed circuit boards. The choice between HASL Lead vs. Lead-Free can significantly affect mechanical reliability, thermal endurance, and resistance to environmental stressors.

1. Thermal Cycling Resistance

Leaded HASL, with its lower melting point and thin intermetallic layer, generally exhibits excellent resistance to thermal cycling. The solder joints can expand and contract with minimal stress, reducing the likelihood of microcracks over repeated heating and cooling cycles. Lead-free HASL, due to its higher melting temperature and thicker intermetallic layer, may be slightly more prone to thermal fatigue. However, careful process optimization—such as controlled ramp rates and soak profiles—can mitigate these effects.

2. Mechanical Stress Tolerance

Mechanical durability is another important consideration. Leaded HASL joints tend to be more ductile, absorbing vibrations and mechanical shocks without cracking. Lead-free HASL joints, while slightly more brittle, still offer acceptable performance in most commercial and industrial applications. High-reliability environments, such as aerospace or automotive electronics, may require additional testing to ensure lead-free joints meet stringent mechanical standards.

3. Corrosion Resistance

Both leaded and lead-free HASL provide a protective tin-based coating over copper pads, which helps resist oxidation and corrosion. Leaded HASL often has a smoother, more uniform coating that can offer slightly better protection in humid or chemically aggressive environments. Lead-free HASL, while compliant with environmental regulations, may require additional protective coatings or conformal coatings in challenging conditions.

4. Shelf Life and Storage Considerations

Leaded HASL boards generally exhibit a longer shelf life due to their stable metallurgical structure, making them less susceptible to oxidation during storage. Lead-free HASL boards may experience slight surface oxidation over time, which can impact solderability if storage conditions are not controlled. Proper handling, anti-oxidation packaging, and storage in a controlled environment are recommended to maintain lead-free HASL quality.

Cost is a major factor influencing the choice between HASL Lead vs. Lead-Free in PCB manufacturing. While performance and regulatory compliance are critical, understanding the economic implications helps manufacturers and designers make informed decisions.

1. Material Costs

Leaded HASL uses a tin-lead alloy, which is generally less expensive than lead-free alternatives such as SAC alloys (SnAgCu). The higher silver content in lead-free alloys contributes to increased raw material costs, making lead-free HASL slightly more expensive from the outset.

2. Processing Costs

The higher melting point of lead-free HASL necessitates higher reflow temperatures and stricter thermal control during soldering. This can increase energy consumption, extend production cycles, and require more sophisticated equipment, further raising the manufacturing cost compared to leaded HASL.

3. Yield and Rework Considerations

Leaded HASL typically produces more predictable soldering results, reducing the likelihood of defects and rework. Lead-free HASL may require more careful process optimization to achieve consistent wetting, which could impact yields if not properly managed. Over time, increased rework and longer cycle times can add to production expenses.

4. Compliance Costs

Lead-free HASL aligns with environmental regulations such as RoHS and WEEE. Using leaded HASL in regulated markets may require additional certifications, restricted use considerations, or even penalties, which can indirectly raise costs. For global products, lead-free HASL ensures compliance and avoids potential regulatory fees.

5. Total Lifecycle Cost

When evaluating HASL Lead vs. Lead-Free, it’s important to consider the total lifecycle cost, not just upfront material expenses. Lead-free HASL may cost more initially but can offer savings in compliance management, environmental safety, and long-term market acceptance. Leaded HASL may reduce immediate costs but could incur additional expenses in regulated markets or for disposal and handling of hazardous materials.

Understanding the detailed process of applying HASL Lead vs. Lead-Free is essential for ensuring consistent quality, optimal solderability, and long-term reliability. While both finishes share a similar workflow, subtle differences in temperature control and handling must be observed for lead-free applications.

1. Surface Preparation

Before HASL coating, the PCB copper pads must be cleaned and free of oxides. This typically involves chemical cleaning, mechanical brushing, or micro-etching to improve solder adhesion. Proper surface preparation is critical for both leaded and lead-free HASL, though lead-free finishes are slightly more sensitive to residual oxides due to higher melting points.

2. Flux Application

A flux layer is applied to the copper pads to remove oxides and enhance wetting during soldering. For leaded HASL, standard rosin or no-clean fluxes are typically sufficient. Lead-free HASL requires fluxes formulated to withstand higher soldering temperatures without degrading or leaving harmful residues.

3. Immersion in Molten Solder

The PCB is then immersed in a bath of molten solder. Leaded HASL baths are typically maintained around 265–275°C, while lead-free HASL requires higher temperatures, usually between 280–300°C, depending on the alloy composition. This step ensures that the solder completely coats all exposed copper surfaces.

4. Hot Air Solder Leveling

After immersion, the PCB passes through hot air knives, which remove excess solder and create a uniform coating. This step is crucial for both leaded and lead-free finishes to ensure consistent pad thickness and prevent bridging or uneven solder surfaces. Lead-free HASL may require more precise air knife settings due to the higher viscosity of the molten alloy.

5. Cooling and Inspection

Once leveled, the boards are cooled to solidify the solder. Automated optical inspection (AOI) is often used to check for solder coverage, smoothness, and potential defects. Lead-free HASL joints are carefully inspected for cold solder joints, surface roughness, and proper intermetallic formation.

6. Final Quality Control

The finished boards undergo final electrical and mechanical testing to verify solderability, pad adhesion, and reliability. Manufacturers like JM PCB emphasize rigorous quality control, ensuring that both leaded and lead-free HASL meet industry standards and client specifications.

7. Packaging and Storage

Proper packaging prevents oxidation and contamination, which is particularly important for lead-free HASL due to its slightly higher susceptibility to surface oxidation. Moisture barrier bags, desiccants, and controlled storage environments help maintain solderability over time.

The choice between HASL Lead vs. Lead-Free offers distinct advantages depending on the application, manufacturing requirements, and regulatory considerations. Understanding these benefits helps PCB designers and manufacturers make informed decisions.

1. Advantages of Leaded HASL

Excellent Solderability: Leaded HASL’s low melting point and eutectic composition ensure smooth wetting and predictable solder joints, reducing assembly defects.

High Mechanical Ductility: The solder joints are more ductile, making them resistant to vibration and mechanical stress. This is particularly beneficial in industrial, automotive, or aerospace applications.

Lower Processing Complexity: Leaded HASL requires slightly lower reflow temperatures and is more forgiving with flux chemistry, reducing energy consumption and simplifying assembly processes.

Longer Shelf Life: Leaded boards are less susceptible to oxidation during storage, maintaining solderability over extended periods.

2. Advantages of Lead-Free HASL

Regulatory Compliance: Lead-free HASL adheres to environmental regulations such as RoHS and WEEE, allowing for global product distribution without compliance issues.

Environmental Safety: By eliminating lead, the boards are safer for workers during production and safer for disposal, minimizing environmental impact.

Suitable for Modern Electronics: Lead-free HASL is ideal for high-volume consumer electronics, medical devices, and other applications where regulatory compliance is mandatory.

Comparable Reliability: With optimized assembly processes, lead-free HASL can achieve solder joint reliability similar to leaded finishes, suitable for most commercial and industrial applications.

Choosing between HASL Lead vs. Lead-Free is a critical decision in PCB manufacturing, impacting solderability, durability, cost, and regulatory compliance. Both finishes offer distinct advantages and challenges, and selecting the right one requires careful consideration of application requirements, environmental regulations, and assembly processes.

Key Takeaways:

Solderability: Leaded HASL provides superior wetting and predictable solder joints, while lead-free HASL requires precise temperature control but can achieve comparable results.

Durability: Leaded HASL offers excellent ductility and thermal cycling resistance, whereas lead-free HASL performs reliably with optimized processes.

Cost: Leaded HASL generally incurs lower material and processing costs, while lead-free HASL ensures compliance with environmental regulations, avoiding potential fines and market restrictions.

Environmental Compliance: Lead-free HASL is aligned with RoHS, WEEE, and global sustainability initiatives, making it suitable for consumer electronics and regulated markets.

Manufacturer Expertise: Partnering with experienced PCB manufacturers like JM PCB helps navigate the complexities of HASL finishes, ensuring consistent quality, reliability, and process optimization.

Final Thoughts:

The choice between HASL Lead vs. Lead-Free is no longer solely about cost or convenience—it involves balancing performance, reliability, compliance, and long-term sustainability. For applications demanding high ductility and lower thermal stress, leaded HASL remains valuable. For environmentally conscious designs and global distribution, lead-free HASL is the preferred solution.

By understanding the scientific principles, process requirements, advantages, and limitations of each finish, PCB designers and manufacturers can make informed decisions that enhance product performance and meet both technical and regulatory expectations.

To provide additional clarity on HASL Lead vs. Lead-Free, here are common questions that PCB designers, manufacturers, and clients often ask, along with detailed answers.

1. What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering superior surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process, making it more flexible and cost-effective. Choice depends on PCB design requirements, such as flexibility, thickness, and signal integrity.

2. Can lead-free HASL match the solderability of leaded HASL?

Yes, with proper process optimization. Lead-free HASL has a higher melting point, requiring precise reflow profiles and flux formulations. With controlled assembly conditions, lead-free HASL can achieve solder joint reliability comparable to leaded HASL.

3. Are leaded HASL boards still allowed in consumer electronics?

In many regulated markets, leaded HASL is restricted due to environmental and health concerns. However, it is still permitted for specialized industrial, military, or aerospace applications where performance requirements outweigh regulatory constraints.

4. How does HASL thickness affect PCB performance?

Excessively thick HASL coatings can interfere with fine-pitch components and cause solder bridging, while insufficient thickness may lead to incomplete coverage and oxidation. Manufacturers use calibrated hot air leveling to ensure consistent and optimal solder layer thickness.

5. What are best practices for storing lead-free HASL PCBs?

Lead-free HASL boards should be stored in moisture barrier bags with desiccants, in temperature- and humidity-controlled environments. Proper storage prevents surface oxidation, preserves solderability, and extends shelf life.

These FAQs provide practical insights into HASL Lead vs. Lead-Free, helping designers and manufacturers make informed decisions while avoiding common pitfalls.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote