Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the seamless operation of devices ranging from smartphones to industrial machinery. Despite their ubiquity, PCBs face a silent yet devastating threat: PCB Corrosion. Unlike visible damage such as cracks or broken traces, corrosion is often invisible until it triggers a catastrophic failure, leading to device malfunctions, costly repairs, and shortened equipment lifespan.

In this article, we will explore the mechanisms behind PCB Corrosion, why proactive cleaning is essential, and how employing quality PCB manufacturers like JM PCB can significantly mitigate these risks.

PCB Corrosion

PCB Corrosion occurs when environmental factors, chemical contaminants, or poor manufacturing processes compromise the copper traces or solder connections on a PCB. Common causes include:

Moisture and Humidity: Water molecules penetrate the protective solder mask, reacting with copper surfaces to form copper oxides and other compounds.

Chemical Contaminants: Flux residues, salts, or environmental pollutants can accelerate corrosion, creating localized “hotspots” that weaken traces.

Electrochemical Reactions: Differences in metal composition on the PCB can lead to galvanic corrosion, especially in high-density or multilayer boards.

Temperature Fluctuations: Thermal cycling induces micro-cracks in protective coatings, exposing conductive materials to environmental hazards.

Unchecked PCB Corrosion can have several serious consequences:

Signal Degradation: Corrosion increases electrical resistance, leading to data loss or signal distortion.

Component Failure: Sensitive electronic components may overheat or fail entirely due to compromised electrical pathways.

System Downtime: Industrial equipment or critical systems face unplanned downtime, impacting productivity and increasing maintenance costs.

Financial Losses: Replacing corroded PCBs is expensive, often requiring complete device replacement rather than targeted repair.

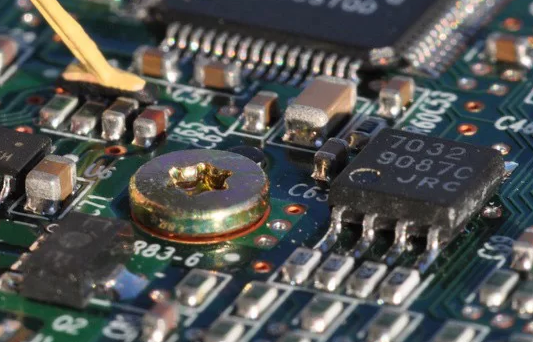

While corrosion is often invisible, careful inspection can reveal early warning signs:

Discoloration or greenish deposits on copper traces.

Rust-like or powdery residues around solder joints.

Unexplained intermittent electrical failures.

Visible pitting or surface roughness under magnification.

Cleaning is not merely cosmetic—it is a critical preventive measure that prolongs device life, ensures reliability, and reduces maintenance costs. By employing a systematic cleaning process, electronics manufacturers and repair specialists can remove corrosive agents before they compromise functionality.

Key benefits of cleaning PCB Corrosion include:

Enhanced Electrical Performance: Cleaning removes oxides and contaminants, reducing resistance and restoring optimal signal integrity.

Increased Longevity: Proper cleaning slows the progression of corrosion, extending the service life of PCBs.

Reduced Repair Costs: Preventive maintenance reduces the frequency of component replacement and unplanned downtime.

Improved Reliability in Critical Applications: For medical devices, aerospace systems, or industrial machinery, corrosion-free PCBs ensure operational safety and compliance.

Tip: Partnering with trusted manufacturers like JM PCB ensures PCBs are produced with corrosion-resistant materials and high-quality protective coatings, minimizing the risk of future degradation.

Cleaning PCB Corrosion involves several careful steps to ensure the integrity of the board is maintained:

Inspection: Use visual inspection and magnification tools to identify corrosion hotspots.

Surface Preparation: Remove dust, loose debris, or oxidation using soft brushes or compressed air.

Chemical Cleaning: Apply specialized PCB cleaning solutions that dissolve corrosion without damaging the copper or solder mask.

Rinse and Dry: Thoroughly rinse off chemical residues with deionized water and dry using controlled airflow.

Protective Coating: Apply conformal coatings or anti-corrosion sprays to prevent recurrence.

Final Testing: Conduct electrical tests to confirm signal integrity and component functionality.

One of the most insidious forms of PCB Corrosion arises from electrochemical reactions. When two dissimilar metals on a PCB come into contact in the presence of an electrolyte (like moisture or flux residues), a galvanic cell forms, accelerating corrosion.

Galvanic Hotspots: Areas around vias, through-hole plating, or mixed-metal components are particularly vulnerable.

Layered Structures: In multilayer PCBs, internal copper layers may corrode unnoticed, compromising the structural integrity and electrical continuity of the board.

The surrounding environment plays a crucial role in the speed and severity of PCB Corrosion:

Humidity and Condensation: High humidity promotes water absorption into solder masks and laminates, triggering oxidation.

Pollutants and Salts: Industrial pollutants or salt from coastal environments can deposit on PCB surfaces, increasing electrochemical activity.

Temperature Extremes: Repeated thermal cycling can expand micro-cracks in coatings, exposing copper to air and moisture.

Vibration and Mechanical Stress: Movement and vibration can wear away protective layers, increasing vulnerability.

Surface Oxidation: Formation of copper oxides on exposed copper traces, often appearing as a green or brown film.

Pitting Corrosion: Small, localized holes or pits that compromise trace conductivity.

Solder Joint Corrosion: Corrosion of soldered connections, leading to intermittent or complete electrical failure.

Interlayer Corrosion: Occurs in multilayer PCBs where inner layers are affected, often undetectable until failure.

Mechanical methods involve physically removing corrosion using non-abrasive tools:

Soft-bristled brushes

Lint-free swabs

Micro-abrasion for stubborn deposits

Caution: Excessive force may damage delicate traces or components.

Chemical cleaning is often the most effective way to combat PCB Corrosion:

Solvent-Based Cleaning: Removes flux residues and light oxidation.

Acidic or Alkaline Solutions: Target tough copper oxides, but must be neutralized and rinsed thoroughly.

Specialized PCB Cleaners: Formulated to dissolve corrosion without harming the board’s materials.

Recommendation: Always test a small area first and follow manufacturer instructions.

For multilayer or densely packed PCBs, ultrasonic cleaning is highly effective:

Uses high-frequency sound waves to agitate cleaning solutions.

Penetrates small crevices, removing debris and corrosion from hard-to-reach areas.

Often followed by deionized water rinsing and careful drying.

After cleaning, applying a conformal coating or anti-corrosion spray is essential to prevent recurrence:

Acrylic coatings for general protection

Polyurethane for chemical resistance

Silicone coatings for high-temperature environments

PCB Corrosion is a silent, costly threat that can compromise electronics performance and longevity. Understanding its causes—environmental factors, electrochemical reactions, and material vulnerabilities—allows engineers and technicians to adopt effective preventive strategies.

Cleaning is not just a maintenance step; it is an investment in reliability. By implementing proper inspection, cleaning, and protective measures, and choosing high-quality manufacturers like JM PCB, companies can:

Extend the lifespan of their electronics.

Reduce unexpected downtime and repair costs.

Maintain consistent performance in critical applications.

Ultimately, the hidden costs of ignoring PCB Corrosion far outweigh the investment in prevention. Routine maintenance, quality materials, and professional manufacturing partnerships form the foundation of corrosion-free, reliable electronic systems.

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

PCB cleaning frequency depends on the operating environment. For devices in humid, salty, or industrial conditions, cleaning every 6–12 months is recommended. Less demanding environments may allow 1–2 years between maintenance cycles. Regular inspection is crucial for early detection of PCB Corrosion.

Minor surface corrosion can often be removed through careful mechanical or chemical cleaning, restoring electrical functionality. However, severe corrosion, especially in multilayer boards or compromised solder joints, may require full PCB replacement. Prevention is far more effective than post-damage repair.

Safe cleaning agents for PCBs include:

Isopropyl alcohol (IPA) for light residues.

Specialized PCB cleaning solutions formulated to dissolve flux and corrosion without damaging solder masks or copper.

Deionized water for rinsing after chemical cleaning.

Avoid abrasive materials or harsh acids unless specifically recommended for corrosion removal.

Hidden corrosion, especially in multilayer PCBs, can be detected using:

X-ray Inspection: Reveals internal layer damage or voids.

Electrical Testing: Resistance measurement can indicate compromised traces.

Thermal Imaging: Overheating areas may indicate high-resistance corrosion spots.

Early detection allows targeted cleaning before full board failure occurs.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote