Printed Circuit Boards (PCBs) form the backbone of modern electronic devices, ranging from everyday gadgets to highly specialized aerospace and communication equipment. While the market offers a variety of PCB materials and types, Rogers PCBs have earned a premium reputation due to their exceptional electrical, mechanical, and thermal properties.

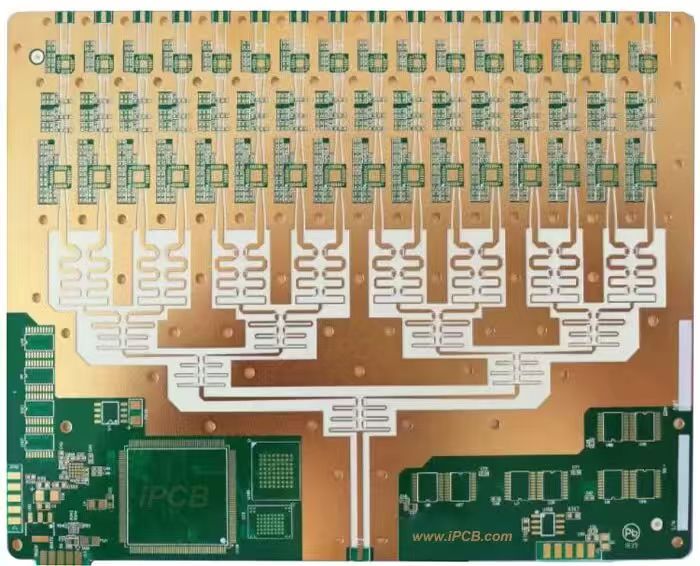

While there are many types of PCBs, one category that stands out for its premium characteristics and cost is the Rogers PCB. These are specialized circuit boards manufactured using materials from Rogers Corporation, a leading innovator in high-frequency laminate materials. Rogers PCBs are designed specifically to meet the demands of high-frequency, high-speed, and high-reliability electronic applications.

The rising adoption of technologies such as 5G telecommunications, aerospace radar systems, satellite communications, and advanced automotive electronics has driven the demand for PCBs capable of maintaining signal integrity and stability at microwave and millimeter-wave frequencies. Rogers PCBs meet these requirements through proprietary materials with superior dielectric and mechanical properties.

However, the benefits come at a significant cost premium compared to standard PCB materials like FR-4, prompting many engineers and buyers to ask: Why are Rogers PCBs expensive? This article aims to break down the key cost factors behind Rogers PCBs, explore their unique features, and provide insight into whether the premium price is justified for your application.

Rogers PCBs are distinguished primarily by the material technology underlying their construction. Unlike conventional PCBs made with standard FR-4 laminates—composed mainly of woven fiberglass and epoxy resin—Rogers PCBs use specially engineered laminates designed for superior electrical performance.

One of the most critical parameters for high-frequency PCBs is the dielectric constant (Dk), which influences signal speed and impedance control. Rogers materials typically have a low and stable dielectric constant (often in the range of 3.0 to 3.7), which remains consistent over a wide frequency range and temperature spectrum. This contrasts with FR-4, where Dk can vary significantly, leading to signal distortion and timing errors.

Additionally, Rogers laminates have an extremely low dissipation factor (Df), which means signal loss due to dielectric heating is minimal. This translates to better signal fidelity, lower insertion loss, and improved overall system efficiency—qualities vital for RF and microwave applications.

Beyond electrical advantages, Rogers PCBs exhibit excellent thermal stability and mechanical robustness. These materials maintain dimensional stability under thermal cycling, preventing warping or delamination that can degrade PCB reliability.

Their higher thermal conductivity compared to FR-4 facilitates efficient heat dissipation, which is essential for high-power RF circuits where excessive heat could otherwise damage components or affect performance.

Because Rogers materials are engineered for demanding applications, manufacturing processes must be adapted. These specialized laminates require precise lamination, drilling, plating, and testing processes to maintain their unique properties. This increased manufacturing complexity contributes significantly to the overall cost of Rogers PCBs.

Understanding why Rogers PCBs carry a higher price tag involves examining the different contributors to their cost. These can be broadly grouped into four main categories:

The raw materials used in Rogers PCBs are proprietary composites developed through extensive research and development. They incorporate advanced polymers, fillers, and reinforcing agents to achieve the desired electrical and mechanical properties. These materials are not only costly to produce but also have limited suppliers, leading to higher acquisition costs.

Rogers PCBs require advanced manufacturing processes that differ substantially from standard PCB production:

These factors increase production time and labor costs.

Applications using Rogers PCBs—such as aerospace or 5G infrastructure—demand near-zero failure rates. This requires rigorous testing protocols, including impedance measurements, thermal cycling, and environmental stress testing. The investment in quality assurance further increases the cost.

Rogers laminates are niche products with a limited number of suppliers worldwide. The supply chain’s tightness combined with high demand in specialized markets drives prices upward. Moreover, global economic conditions, raw material shortages, and shipping costs all impact the final PCB price.

At the heart of Rogers PCB pricing is the cost of the laminate material itself. The Rogers Corporation invests heavily in developing materials that provide consistent electrical performance and mechanical reliability across a wide range of applications.

For example, the widely used RO4000 series laminates are engineered to deliver low dielectric loss, stable Dk, and excellent thermal management. These laminates combine high purity fiberglass weaves with proprietary resin systems and fillers that enhance their microwave frequency performance.

Such engineered materials are not commodities but high-value products that require sophisticated manufacturing techniques and quality control. Consequently, the raw material cost alone can be several times that of standard FR-4 laminates.

Because these features require highly specialized raw materials and manufacturing processes, Rogers PCBs come with a significantly higher price tag compared to conventional PCBs.

Producing Rogers PCBs is more demanding than standard PCBs due to:

This complexity naturally translates into higher labor and operational costs.

Despite the higher cost, Rogers PCBs are indispensable for high-frequency and high-reliability applications. Their superior performance leads to:

For mission-critical projects, these benefits outweigh the initial investment in higher-cost PCBs.

The specialized nature of Rogers PCBs means fewer manufacturers can produce them at scale. Demand from cutting-edge industries such as 5G infrastructure, defense, and aerospace is growing rapidly, putting pressure on supply chains and driving prices higher.

Moreover, global supply chain disruptions and raw material shortages have exacerbated cost increases in recent years.

For companies and engineers seeking reliable Rogers PCBs, JM PCB is an excellent choice. Known for their expertise in high-frequency PCB fabrication, JM PCB offers precision manufacturing combined with stringent quality control to ensure customers receive consistent, top-tier products.

Their experience with Rogers materials and dedication to customer service make them a trusted supplier in the industry.

While Rogers PCBs are generally 3 to 5 times more expensive than standard FR-4 boards, this comparison should be contextualized by application requirements. For high-frequency applications, the cost benefits of reduced signal loss and increased reliability justify the premium.

Standard FR-4 boards are suitable for low-frequency, low-cost applications, but fall short when precision and performance are paramount.

Rogers PCBs command a premium price due to advanced materials, complex manufacturing, and superior performance characteristics critical for RF, aerospace, and high-speed digital applications. While they may not be necessary for every project, in scenarios demanding signal integrity and reliability, their cost is justified.

Choosing a trusted manufacturer like JM PCB ensures you get the best value and quality in Rogers PCBs.

Q1: What is the difference between rolled copper foil and electrolytic copper foil?

Rolled copper foil is produced by mechanically rolling copper into thin sheets, offering better surface quality and mechanical strength. Electrolytic copper foil is deposited via an electrolytic process and is more flexible and cost-effective.

Q2: Can Rogers PCBs be used in standard consumer electronics?

While technically possible, Rogers PCBs are usually reserved for high-frequency or high-reliability applications due to their higher cost.

Q3: How does the dielectric constant affect PCB performance?

A lower and stable dielectric constant reduces signal loss and timing delays, which is critical for high-speed and RF circuits.

Q4: Are Rogers PCBs more environmentally friendly?

Rogers materials comply with environmental regulations, but their production is resource-intensive compared to standard FR-4.

Q5: Where can I get Rogers PCBs manufactured quickly and reliably?

JM PCB specializes in Rogers PCB manufacturing with rapid turnaround times and stringent quality control.

Connect to a Jerico Multilayer PCB engineer to support your project!

Request A Quote